Erosion Control HDPE Typar Geocell Material for Road

HDPE (High-Density Polyethylene) geocells are commonly used in erosion control and road construction applications. Geocells are three-dimensional cellular structures made from HDPE panels that are connected together to form a grid-like system. These geocells are then filled with soil, aggregate, or other infill materials to create a stable and reinforced structure.HDPE geocells are highly resistant to chemical degradation and environmental factors such as ultraviolet (UV) radiation. They have a long service life and can withstand harsh weather conditions, making them suitable for long-term erosion control applications.

HDPE geocells offer a cost-effective and environmentally friendly solution for erosion control in road construction. They provide stability, load-bearing capacity, and protection against erosion, making them a valuable tool in promoting sustainable infrastructure development.

In modern road construction and infrastructure engineering, erosion control and soil stabilization are two of the most crucial challenges. Without proper reinforcement, roads built on soft, unstable ground can fail prematurely, resulting in high maintenance costs and safety hazards. That’s where Erosion Control HDPE Typar Geocell Material for Road comes into play.

This innovative geosynthetic solution is designed to provide long-lasting soil confinement, reduce erosion, and improve the performance of roads, embankments, and load support systems.

🌍 What Is Erosion Control HDPE Typar Geocell Material for Road?

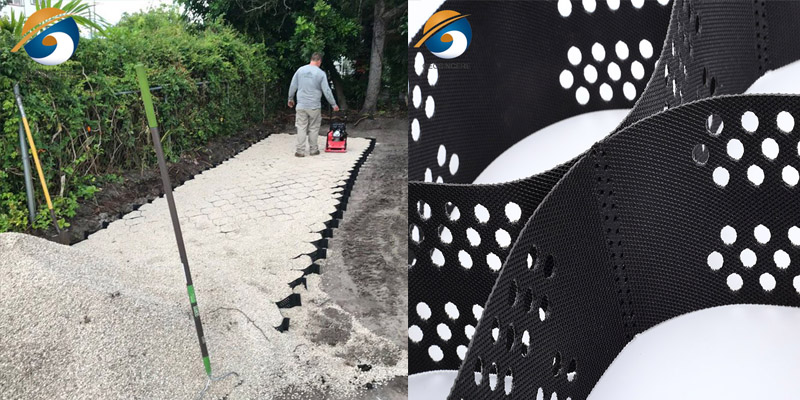

Erosion Control HDPE Typar Geocell Material for Road is a three-dimensional, honeycomb-like cellular structure made from high-density polyethylene (HDPE). When expanded and filled with soil, sand, gravel, or other infill materials, it forms a highly stable layer that resists lateral movement and erosion.

Unlike traditional geotextiles or mesh products, this system creates load distribution and erosion protection in one integrated structure, making it ideal for unpaved roads, gravel paths, slopes, and low-bearing soils.

✅ Key Benefits of Erosion Control HDPE Typar Geocell Material for Road

🌧️ Superior erosion control on slopes and roadside shoulders

🚚 Enhanced load-bearing capacity for weak soil bases

🧱 Reduces rutting, potholes, and base layer degradation

♻️ Environmentally safe and recyclable HDPE material

🛠️ Quick and easy to install in remote or uneven terrains

⏳ Durable performance with UV, chemical, and water resistance

The Erosion Control HDPE Typar Geocell Material for Road is designed to last over 50 years in outdoor environments, ensuring long-term infrastructure performance.

🛣️ Applications of Erosion Control HDPE Typar Geocell Material for Road Projects

This advanced solution is trusted in a wide range of civil engineering and infrastructure applications, including:

Rural and forest road reinforcement

Access roads for mining, energy, and oil projects

Steep slope protection and erosion control

Road shoulder stabilization

Unpaved and gravel road systems

Rail bed support

Construction site access roads

Temporary or permanent haul roads

For any project requiring both load support and erosion resistance, Erosion Control HDPE Typar Geocell Material for Road delivers unbeatable performance.

🧪 Technical Features of Erosion Control HDPE Typar Geocell Material for Road

Material: High-Density Polyethylene (HDPE)

Cell height: Available in 50mm, 75mm, 100mm, 150mm

Welding distance: Customizable (330mm to 660mm)

Color: Black, green, or as requested

Perforated or solid cell walls

UV stabilized for long-term outdoor use

These features ensure that Erosion Control HDPE Typar Geocell Material for Road meets or exceeds international standards for geosynthetic performance.

⚙️ How It Works: The Science Behind the Strength

The power of Erosion Control HDPE Typar Geocell Material for Road lies in its cellular confinement system:

Confinement: The honeycomb structure confines infill material, reducing lateral movement.

Load Distribution: It disperses loads over a wide area, reducing pressure on subgrade.

Erosion Resistance: Prevents soil loss from wind, rain, and runoff.

Stabilization: Improves bearing capacity and reduces deformation under repeated traffic loads.

The result? A robust and reliable roadbed that withstands harsh conditions without failure.

🧱 Installation of Erosion Control HDPE Typar Geocell Material for Road

Installing Erosion Control HDPE Typar Geocell Material for Road is simple and efficient:

🔧 Step-by-Step Process:

Site Preparation: Clear vegetation and debris; level the ground.

Geotextile Base (Optional): Place a separation layer if required.

Geocell Deployment: Expand and position the geocell panels across the subgrade.

Anchoring: Secure cells with rebar, stakes, or anchors.

Infill: Use soil, gravel, sand, or concrete as infill material.

Compaction: Compact the infill to ensure uniform performance.

Surface Finish: Apply the final layer or pavement if needed.

The Erosion Control HDPE Typar Geocell Material for Road can adapt to curved, sloped, or uneven terrain with ease.

🏗️ Why Choose Typar HDPE Geocell Material Over Traditional Systems?

While conventional geogrids and geotextiles serve specific purposes, Erosion Control HDPE Typar Geocell Material for Road offers comprehensive performance in a single system:

| Feature | Traditional Geotextile | Typar Geocell |

|---|---|---|

| Load support | Moderate | Excellent |

| Erosion control | Limited | High |

| Flexibility | High | High |

| Cost-efficiency | Medium | High |

| Long-term durability | Good | Excellent |

| Environmental impact | Varies | Recyclable, non-toxic |

In short, Erosion Control HDPE Typar Geocell Material for Road is the smarter, stronger, and more sustainable choice.

🌱 Eco-Friendly Infrastructure with HDPE Geocell Systems

As green construction becomes a global trend, Erosion Control HDPE Typar Geocell Material for Road supports sustainability goals:

Reduces the need for thick base layers

Minimizes material transportation and CO₂ emissions

Fully recyclable HDPE plastic

Promotes re-vegetation on slopes and embankments

Requires less maintenance over time

This makes it a go-to solution for eco-conscious civil engineering.

🧩 FAQs: Erosion Control HDPE Typar Geocell Material for Road

Q1: How long does HDPE geocell last in the field?

Typically 50+ years with proper installation.

Q2: Is it suitable for high-traffic roads?

Yes, when properly installed with the right infill, it can support heavy loads.

Q3: Can I use it on steep slopes?

Absolutely. It’s designed for steep gradient erosion control.

Q4: What infill works best?

Common options include gravel, sand, crushed stone, and concrete.

🚀 Conclusion: Build Stronger, Safer Roads with HDPE Geocell Technology

If you’re planning a road construction or erosion control project, Erosion Control HDPE Typar Geocell Material for Road offers a high-performance, low-maintenance, and cost-effective solution. Whether you're reinforcing a gravel path in a rural village or constructing an access road in an industrial zone, this material delivers unmatched strength, stability, and sustainability.

🛒 Looking for a Reliable Supplier of Erosion Control HDPE Typar Geocell Material for Road?

Choose a manufacturer that offers:

Customized cell size and panel dimensions

Fast delivery and global shipping

Technical support for project design

ISO and CE certified products

Invest in the future of infrastructure with Erosion Control HDPE Typar Geocell Material for Road — engineered for performance, built for durability.

HDPE geocells have a perforated design that allows for proper water drainage. They facilitate the flow of water through the cells, preventing the accumulation of water and reducing the risk of water-related damage, such as erosion and saturation of the roadbed.HDPE geocells are highly durable and resistant to environmental factors such as UV radiation, chemicals, and biological degradation. They can withstand long-term exposure to harsh weather conditions, ensuring a prolonged service life and cost-effective erosion control solution for road projects.

Geocells are lightweight and easy to install, making them a convenient choice for erosion control in road construction. They can be quickly deployed and filled with the desired infill material, reducing construction time and costs.By using HDPE geocells for erosion control in road construction, engineers and contractors can effectively address erosion issues, improve road stability, and enhance the overall performance and longevity of the road infrastructure.

Parameter

Product Type | Height (mm) | Welding Distance (mm) | Thickness (mm) | Tensile Strength of Welding Points (N/cm) | Tensile Strength of Connection of Cells (N/cm) | Tensile Strength at Yield of Each Sheet (MPa) |

Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Not | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Erosion Control HDPE Typar Geocell Material for Road for Road Features