60 Mil HDPE Liner Cost

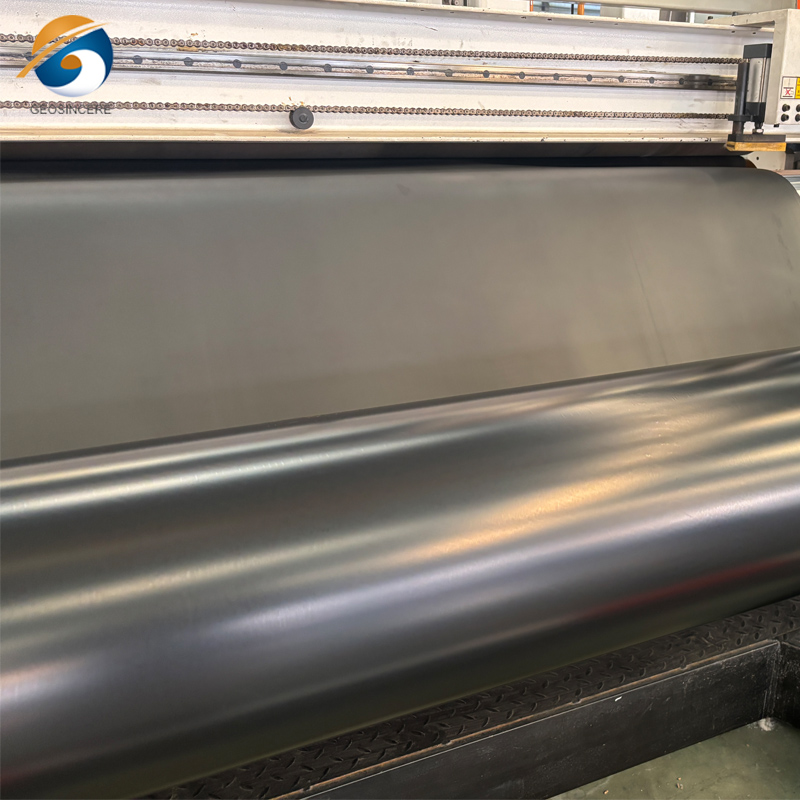

The 60 Mil HDPE Liner is a high-strength, tough geomembrane mainly used in water retention, containment, and environmental protection projects. This HDPE liner is widely known for its outstanding chemical resistance, its flexibility, and a service life that can be counted in decades. Therefore, it is suitable for such applications as ponds, canals, landfills, and mining containment areas, among others.

- Thickness & Strength: 60 mil (1.52 mm) HDPE offers superior resistance to punctures and tears.

- Chemical & UV Resistance: It is quite capable of enduring strong chemicals, acids, and exposure to UV for a long time.

- Flexible & Easy to Install: Despite its strength, it is lightweight, thus facilitating on-site handling and installation.

- Versatile Applications: It can be used for different purposes like water reservoirs, mining ponds, landfill liners, canal lining, and industrial containment without any issue.

- Cost-Effective Solution: It combines the qualities of being durable and affordable at the same time, thus giving a great return for large-scale projects over the long term.

60 Mil HDPE Liner is a high-quality geomembrane, which has been specifically designed for tough containment and waterproofing applications. Having a thickness of 60 mil (1.52 mm), this HDPE liner is a perfect mix of strength, flexibility, and price efficiency. It finds its application in the environmental protection, water management, mining, and industrial sectors where it becomes essential to have impermeability and durability over extended periods.

1. 60 Mil HDPE Liner Cost Material Composition and Manufacturing

1.1 High-Density Polyethylene Resin

This hdpe pond liner has been made from the finest quality high-density polyethylene (HDPE) resin, selected mainly due to its amazing strength, flexibility, and chemical stability. The use of this raw material guarantees long-term durability and consistent performance in the toughest of containment environments.

1.2 Advanced Extrusion and Calendering Technology

The current extrusion and calendering processes are capable of achieving very precise thickness control as well as a uniformly structured membrane. These technologies not only improve the mechanical strength but also result in a smooth and defect-free surface area of the hdpe geomembrane, which is beneficial in many ways.

1.3 UV Stabilizers for Weather Resistance

UV stabilizers have been added during the production process to prevent the 60 mil hdpe liner from deteriorating due to its exposure to sunlight for a long time. This greatly increases the lifespan of the geomembrane pond liner both in the case of exposed as well as buried installations.

1.4 Antioxidants for Aging and Oxidation Resistance

Antioxidants help the geomembrane sheet resist resisting thermal aging and oxidation, thus making the liner more stable and allowing it to maintain its physical properties even after it has been subjected to long-term environmental stress.

1.5 Environmental Stress Crack Resistance (ESCR)

The component composition has been adjusted so as to further improve the resistance of the hdpe geomembrane liner to environmental stress cracking, thus lowering the likelihood of the membrane breaking down due to heavy load, temperature fluctuations, and chemical exposure.

1.6 Strict Quality Control and Inspection

After every production batch, strict quality control testing is performed to verify the uniformity of the thickness and density and also the stability of mechanical performance throughout the entire roll.

1.7 Smooth and Consistent Surface Finish

Carefully regulated manufacturing conditions yield a smooth, flawless surface finish, thus resulting in an improved welding quality and ensuring a reliable seam strength at the time of the installation.

2. 60 Mil HDPE Liner Cost – Mechanical Strength and Durability

2.1 High Tensile Strength

With this 60 mil HDPE liner, you get incredible tensile strength, which means it is capable of enduring very high pulling forces during its installation and use over a long period, without getting torn or stretched beyond a reasonable limit.

2.2 Superior Puncture Resistance

At 1.5 mm thickness, it is quite tough to get damaged by punctures through sharp stones, debris, or rough subgrade surfaces, thus your containment performance will be the least of your worries.

2.3 Excellent Tear Resistance

It is designed in such a way that it can resist tearing, and this is a great aid to preventing damage that might occur when it is being handled, welded, and used in environments where there are heavy loads.

2.4 Flexibility Under Load

To the surprise of some, and despite its thickness, the high density polyethylene pond liner didn't lose its flexibility; thus, it's capable of adjusting to an uneven subgrade and even accommodating small ground displacements without getting cracks.

2.5 Resistance to Cracking and Deformation

The durable makeup of the material hardly ever results in the production of cracks, splits, or permanent deformations, even after it has been subjected to continuous mechanical stress and heavy loads.

2.6 Performance in Temperature Fluctuations

The hdpe liner sheet is able to preserve its properties related to mechanics along with a wide range of temperatures; therefore, hdpe dam liners is dependable both in extreme heat and cold without a decrease of its strength.

2.7 Long-Term Durability

The 60 mil HDPE liner, which is a product of great workmanship, hardly ever loses its mechanical stability and structural integrity which results in minimized maintenance and replacement expenses.

3. 60 Mil HDPE Liner Cost – Chemical Resistance and Environmental Protection

3.1 Resistance to Acids and Alkalis

By virtue of the hdpe geomembrane 1.5 mm, an outstanding resistance to a vast range of acids and alkalis which are the typical components of the industrial and municipal waste streams, has been observed. This chemical stability guarantees the containment performance over a more extended period without material degradation or loss of mechanical strength.

3.2 Salt and Chemical Solution Compatibility

1.5 mm hdpe liner possess a highly resistant characteristic when it comes to exposure to saline environments and chemical solutions, thus they are very suitable for being used in situations where there is exposure to a high concentration of salt, brines, and aggressive chemical mixtures.

3.3 Performance in Industrial Effluents and Wastewater

The hdpe impermeable liner shows a perfect ability to sustain exhausting contact with industrial effluents and wastewater that contain hydrocarbons, solvents, and other contaminants. In this way, the impermeability of the wastewater treatment plants and industrial containment systems is ensured at all times.

3.4 Landfill Leachate Resistance

The 60 mil HDPE liner has been specifically designed for landfill applications and, therefore, it is resistant to the chemically complex landfill leachate. HDPE membrane sheet is also a barrier to the penetration of chemicals and, at the same time, 60 mil hdpe geomembrane is the protector of the surrounding soil and groundwater from getting contaminated.

3.5 Mining and Tailings Containment Protection

Such a hdpe geomembrane pond liner performs reliably in mining environments, is able to resist the nature of acidic leach solutions and mineral processing chemicals. Therefore, the chemical resistance of the leach pads and tailings ponds is supported.

3.6 Environmental Compliance and Safety

Strict environmental protection requirements are met by the current version of the 60 mil HDPE liner, and it is a shelf and a perfect choice when it comes to applications that require regulatory compliance. Its proven performance plays a great role in the achievement of environmental standards through waste containment and water protection.

3.7 Long-Term Environmental Protection Value

The polyethylene pond liners are a great contributor to the soil and groundwater protection by being a barrier against the leakage and chemical migration. Its excellent resistance to chemicals and long service life are factors that defeat the risk of environmental incidents and, consequently, bring the reduction of the long-term cost of remediation.

4. Factors Affecting 60 Mil HDPE Liner Cost

4.1 Raw Material Quality and Resin Grade

The cost of the hdpe liner pond is generally dependent on the quality and grade of the HDPE resin; therefore, usually, the initial costs of premium resins that have better chemical resistance, UV stability, and stress crack resistance are higher but they reward the user with superior performance in the long run.

4.2 Roll Width and Length Specifications

The high density polyethylene liner which have been manufactured of wider and longer rolls may be the reason for less welding on-site as well as less installation time; however, it might be the case that there will be an increase in costs of manufacturing and transportation because of the requirement for specialized equipment and handling.

4.3 Customization Requirements

When it comes to demanding features such as specific thickness tolerances, colors, textures, or project-specific formulations, the discussion of pricing comes up. Tailored solutions indeed achieve better results when they are applied to particular cases, thus the input cost gets deserved.

4.4 Surface Type: Smooth or Textured

Textured 60 mil HDPE liner have a higher unit price than smooth liners because they go through extra processing. On the other hand, textured surfaces increase friction and help stabilize the slope, thus, the risk of high density polyethylene geomembrane sliding on inclined applications is greatly minimized.

4.5 Order Quantity and Project Scale

Large-volume orders typically enjoy the advantage of lower prices. Making bulk orders for a large-scale project can bring down the rate per square meter drastically as compared to the ones for small orders.

4.6 Transportation and Logistics

Final costs are impacted by the distance of shipment, packaging method, and transport conditions. You may have to pay extra for logistics in international projects especially if the rolls are oversize.

4.7 Installation Conditions and Methods

The overall expenses of the project can be influenced by complex site conditions, refabrication welding requirements, and high labor costs. The less complicated a hdpe geomembrane sheet is for installation and welding the more total installed cost is lowered.

4.8 Long Service Life and Low Maintenance Value

Polyethylene geomembrane is true that thicker liners are more expensive at the initial stage, however, their long service life and low maintenance requirements make the 60 mil hdpe geo membrane a budget-friendly option when we talk about the whole project lifecycle.

5. 60 Mil HDPE Liner Cost – Packaging, Transportation, and Export Experience

5.1 Roll Packaging for International Transportation

The tightly rolled qty of GEOSINCERE 60 mil HDPE liners feature an inner core (protected). Outer pipe wraps help avoid deformation, dirt, and damages caused by transport and repeated handling.

5.2 Customized Roll Size for Container Optimization

Containers can be loaded with higher efficiency when roll width, length, and diameter are adjusted. By selecting the correct measurements of the rolls, we are able to optimize the use of the container space and lower the shipping cost per square meter as well.

5.3 Efficient Container Loading and Logistics Planning

Our hdpe liner material can be loaded most efficiently in standard 20-foot and 40-foot containers. Clever loading plans result in minimizing the space not used, lowering freight cost, and guaranteeing the safety of the shipped content in large-volume international orders.

5.4 Export-Grade Packaging Standards

All packaging materials comply with export standards, providing moisture resistance and protection against mechanical damage during sea and land transport.

5.5 Extensive Global Export Experience

GEOSINCERE Geosynthetics is a globally recognized supplier that has a vast experience of 60 mil hdpe pond liner sheet implementation in international projects such as landfills, mining operations, and wastewater treatment facilities.

6. 60 Mil HDPE Liner Cost – FAQ

Q1: How much does a 60 mil HDPE liner cost per square meter?

A: The price mainly depends on the resin grade, surface type (smooth or textured), order quantity, and shipping conditions. Larger orders generally get better pricing. Please, provide your project-specific details for the exact price quotation.

Q2: How is the cost of 60 mil HDPE liner price kept in balance compared to the price of 40 mil or 80 mil liners?

A: The cost of 60 mil comes out as one more than 40 mil, liner but the 60 mil liner is hugely more durable and resistant to puncturing. It is a cost-saving solution as compared to 80 mil liner for projects that do not require heavy-duty thickness.

Q3: Does having a textured surface on a 60 mil HDPE liner increase the cost of the liner?

A: It might usually. Textured liners are generally priced higher than smooth ones simply because of the extra manufacturing steps, but they give better friction and slope stability, which means less risk during the installation on the incline.

Q4: Which elements are mostly affecting the overall cost of the installation?

A: The main components are liner thickness, roll size, surface type, welding method, site conditions, labor costs, and transportation distance.

Q5: How many years does the 60 mil HDPE liner last in service?

A: A 60 mil HDPE liner used correctly can last to provide service for about 20–30 years or even more depending on the environmental conditions and how it is used.

Q6: Is it possible for 60 mil HDPE liners to have a personal touch?

A: Yes. It is possible to personalize the dimensions of the rolls, the surface texture, and the packaging to fit perfectly the project needs, which in return might change the overall cost.

Q7: Could a 60 mil HDPE liner work out as a cost-effective solution for enormous projects?

A: Sure. Exactly, it is a 60 mil HDPE liner that through its longevity, minimal upkeep, and excellent performance, outweighs its initial higher price versus thinner liners making it the most cost-effective option at the end of the project lifecycle.

Conclusion

The 60 Mil HDPE Liner is a dependable, durable, and cost-effective geomembrane made to meet containment and waterproofing project requirements. Besides that, its outstanding mechanical strength, chemical resistance, and impermeability make it a top choice for engineers and contractors looking for long-term performance and value.

In order to provide top quality and a dependable supply, GEOSINCERE Geosynthetics is the one that has premium 60 mil HDPE liners coming from factories where strict quality control and international standards are firmly observed. Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) has been experience in landfill, mining, and wastewater projects around the globe. They offer tailor-made solutions, stable delivery, and professional technical support to ensure successful project outcomes.