HDPE Pond Liner Manufacturer

GEOSINCERE HDPE pond liners are designed to provide exceptional durability and longevity for various applications, including agricultural ponds, fish farms, and recreational water features. Manufactured using high-quality raw materials, our liners are resistant to UV radiation, chemicals, and punctures, ensuring that they can withstand harsh environmental conditions. The liners are available in various thicknesses and sizes to suit different project requirements, offering a reliable solution for effective water containment.

GEOSINCERE advanced manufacturing processes ensure consistency in quality, with strict adherence to industry standards. Each liner undergoes rigorous testing to guarantee impermeability and flexibility, allowing for easy installation even in challenging terrains. Additionally, our HDPE liners are environmentally friendly, being fully recyclable while providing a safe habitat for aquatic life.

We pride ourselves on our commitment to customer satisfaction, offering tailored solutions and technical support to help clients choose the right liner for their specific needs. With a focus on innovation and quality, our HDPE pond liners are the ideal choice for anyone looking to create sustainable water features that last for years to come.

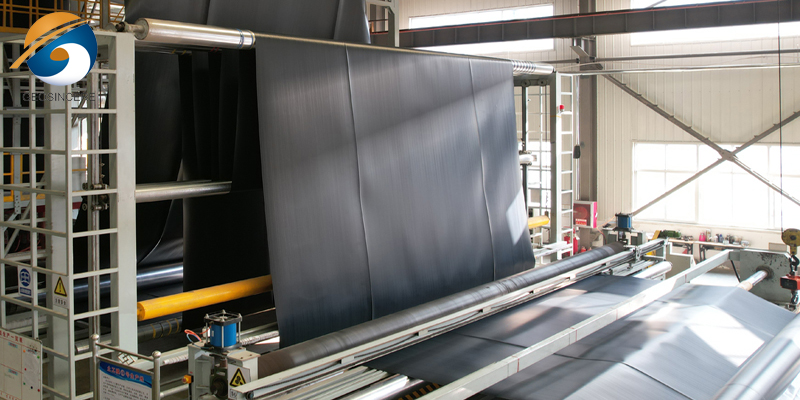

GEOSINCERE High-Density Polyethylene HDPE pond liners are essential for ensuring the integrity and longevity of water features in both residential and commercial settings. As a leading manufacturer of HDPE pond liners, we utilize advanced manufacturing techniques to produce high-quality liners that are UV-resistant, chemical-resistant, and impervious to water, making them ideal for various applications including fish ponds, ornamental ponds, and water gardens. Our liners are designed to withstand extreme weather conditions, ensuring durability and resilience over time. With thickness options ranging from 20 to 120 mils, our HDPE liners can be tailored to meet specific project requirements, providing excellent puncture resistance and flexibility for easy installation. Additionally, our products are environmentally friendly and contribute to sustainable water management practices. By choosing our HDPE pond liners, customers can rest assured that they are investing in a reliable solution that enhances the aesthetic appeal of their landscapes while maintaining water quality and reducing maintenance costs.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

HDPE Pond Liner Manufacturer Features

1. Durability: HDPE pond liners are highly resistant to punctures, tears, and UV degradation, ensuring a long lifespan even in harsh environmental conditions.

2. Chemical Resistance: These liners can withstand a variety of chemicals, including fertilizers and pesticides, making them suitable for agricultural applications and ornamental ponds.

3. Waterproof: Designed to be completely impermeable, HDPE liners effectively prevent water loss, helping to maintain the integrity of ponds and water gardens.

4. Flexibility: The material's flexibility allows for easy installation in various shapes and sizes, accommodating different pond designs without compromising performance.

5. Custom Thickness Options: Available in a range of thicknesses from 20 to 120 mils, HDPE liners can be tailored to meet specific project needs, providing enhanced protection for deeper or more rugged installations.

6. Eco-Friendly: Made from recyclable materials, HDPE pond liners promote environmentally sustainable practices in water management and landscaping.

7. Temperature Resistance: These liners are designed to withstand extreme temperatures, ensuring performance in both hot and cold climates without cracking or degrading.

8. Low Maintenance: The robust nature of HDPE liners reduces the need for frequent repairs or replacements, resulting in lower maintenance costs over time.

9. Easy Installation: Lightweight and manageable, HDPE liners can be installed quickly and efficiently, allowing for faster project completion.

10. Aesthetic Appeal: Available in various colors and finishes, HDPE pond liners can enhance the visual appeal of water features, blending seamlessly with natural landscapes.

Applications of HDPE Pond Liner Manufacturer

High-Density Polyethylene (HDPE) pond liners are essential components in modern water containment systems used in aquaculture, agriculture, mining, and environmental engineering. Choosing the right HDPE pond liner manufacturer is critical to ensuring long-term performance, regulatory compliance, and cost-efficiency. This article explores key technical considerations, material standards, manufacturing processes, and how to select a reliable supplier.

Table of Contents

What Is an HDPE Pond Liner?

Key Applications Across Industries

Properties of High-Quality HDPE Liners

HDPE Pond Liner Manufacturing Process

Industry Standards and Regulatory Compliance

How to Evaluate an HDPE Pond Liner Manufacturer

Common Issues and Technical Solutions

Frequently Asked Questions (FAQs)

Conclusion & Professional Call to Action

1. What Is an HDPE Pond Liner?

HDPE pond liners are flexible geomembranes made from high-density polyethylene polymer resins. They act as impermeable barriers designed to prevent the leakage of fluids in both exposed and buried containment applications.

Key Features:

High chemical resistance

Excellent UV and ozone durability

High tensile strength and elongation

Low permeability (typically < 1.0 × 10⁻¹³ cm/s)

Long service life: 20–50 years depending on exposure

2. Key Applications Across Industries

| Industry | Application |

|---|---|

| Aquaculture | Lining fish/shrimp ponds to prevent seepage and contamination |

| Agriculture | Water storage ponds, canal lining |

| Mining | Heap leach pads, tailings ponds, process water containment |

| Waste Management | Landfill liners, leachate ponds |

| Environmental Engineering | Constructed wetlands, stormwater ponds, biogas digesters |

3. Properties of High-Quality HDPE Liners

A reliable HDPE pond liner manufacturer ensures that each product meets the following performance criteria:

| Property | Standard Requirement | Test Method |

|---|---|---|

| Thickness | 0.5mm to 2.5mm (±10%) | ASTM D5199 |

| Tensile Strength | ≥ 16 MPa | ASTM D638 |

| Elongation at Break | ≥ 700% | ASTM D638 |

| Tear Resistance | ≥ 120 N | ASTM D1004 |

| Carbon Black Content | 2.0%–3.0% | ASTM D4218 |

| Environmental Stress Cracking | ≥ 500 hours | ASTM D5397 (notched constant tensile load test) |

4. HDPE Pond Liner Manufacturing Process

Step 1: Resin Selection

Only virgin polyethylene resin (minimum 97.5%) with appropriate carbon black and antioxidant additives should be used.

Step 2: Extrusion

Through blown film or flat die extrusion, the polymer is melted and formed into sheets of uniform thickness.

Step 3: Cooling and Surface Texturing

Sheets are cooled and optionally embossed to produce textured geomembranes for improved friction in slope applications.

Step 4: Quality Control Testing

Each roll is subjected to dimensional, mechanical, and visual inspection, as well as laboratory tests per GSI GM13 and ISO 9001:2015 protocols.

5. Industry Standards and Regulatory Compliance

Manufacturers should comply with the following international standards and environmental regulations:

GSI GM13: Standard Specification for HDPE Geomembranes

ISO 9001:2015: Quality Management Systems

ASTM D5885: Multi-axial Tension Test

EPA 40 CFR Part 258: Liners for municipal solid waste landfills

CE Certification (EU): Required for European market exports

NSF/ANSI 61: Certification for drinking water system components

6. How to Evaluate an HDPE Pond Liner Manufacturer

✔ Certification & Accreditation

Ensure the factory is certified under ISO 9001, CE, and optionally NSF for potable applications.

✔ Raw Material Control

Top-tier manufacturers use only virgin resin. Ask for Material Safety Data Sheets (MSDS) and certificates of origin.

✔ In-House Testing Laboratory

A professional facility will have tensile testers, oven aging chambers, and permeability testers for on-site quality control.

✔ Welding & Installation Support

Leading manufacturers provide:

Trained technicians

On-site supervision

Technical guides for hot wedge welding and extrusion welding

✔ Project Portfolio & References

Check for past engineering projects, export records, and feedback from high-compliance markets such as the EU, USA, and the Middle East.

7. Common Issues and Technical Solutions

| Problem | Cause | Solution |

|---|---|---|

| Liner puncture | Improper subgrade preparation | Use geotextile cushion layer |

| Seam leakage | Poor welding techniques | Use double-track hot wedge welders with non-destructive testing (ASTM D4437) |

| UV degradation | Prolonged exposure without cover | Use liners with ≥2% carbon black content and cover with soil or concrete |

| Slippage on slopes | Smooth liner on steep terrain | Use textured HDPE liners with high interface friction angle (≥30°) |

8. Frequently Asked Questions (FAQs)

Q1: What is the ideal thickness for a pond liner?

For aquaculture: 0.75mm to 1.0mm, for mining or landfills: 1.5mm to 2.0mm, depending on the design and regulatory requirement.

Q2: How long do HDPE liners last?

HDPE liners can last 20–50 years, depending on UV exposure, mechanical load, and chemical exposure.

Q3: Can HDPE liners be repaired on-site?

Yes. Damaged areas can be repaired via hot air extrusion welding or patching, provided the surface is clean and dry.

Q4: What’s the temperature range for HDPE liner operation?

HDPE can operate between -60°C to +60°C, making it suitable for diverse climates.

Q5: Is HDPE environmentally friendly?

Yes. HDPE is chemically inert and recyclable. Modern liners are manufactured with low VOC emissions and are compliant with RoHS and REACH standards.

9. Conclusion & Professional Call to Action

Selecting the right HDPE pond liner manufacturer is more than just comparing prices—it's about ensuring quality, durability, environmental compliance, and professional support. The success of your containment project depends on liners that meet international engineering standards and manufacturers who provide end-to-end technical service.