HDPE Geogrid

HDPE Geogrid is a high-strength geosynthetic material made from high-density polyethylene, designed for soil reinforcement and stabilization in civil engineering projects. It provides top notch tensile strength, chemical resistance, and long-term durability, making it perfect for enhancing floor shape and extending the lifespan of development works.

- High Tensile Strength: Provides most fulfilling reinforcement for soil, slopes, and holding structures.

- Durable and Weather-Resistant: Resistant to UV radiation, aging, and environmental stress cracking.

- Chemical and Biological Stability: Performs nicely in acidic, alkaline, and saline soil conditions.

- Easy Installation: Lightweight fabric simplifies transportation and on-site handling.

- Wide Applications: Commonly used in roadbeds, protecting walls, embankments, railways, and landfill projects.

HDPE Geogrid from GEOSINCERE Geosynthetics is a high-strength geosynthetic reinforcement material made from top class high-density polyethylene (HDPE) via superior extrusion, punching, and stretching technologies. This specific manufacturing technique creates a strong grid shape that can provide incredible tensile strength, dimensional stability, and interlocking overall performance with surrounding soil or aggregates.

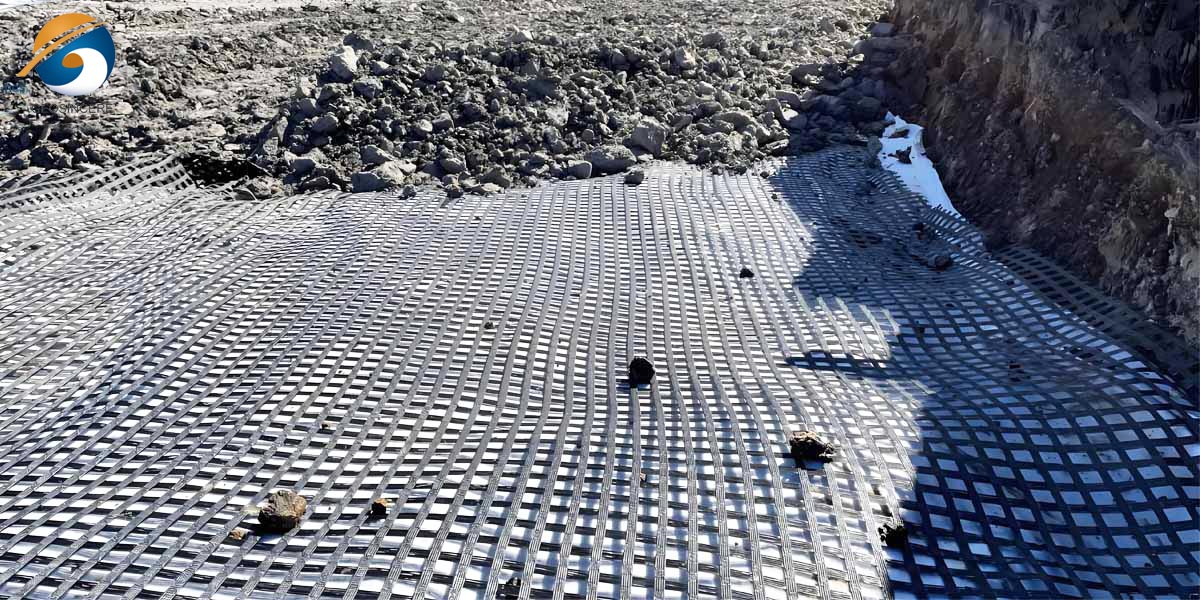

Engineered to decorate soil balance and load-bearing capacity, the HDPE Geogrid successfully distributes utilized loads, reduces differential settlement, and improves the average structural integrity of foundations. It is extensively used in avenue base reinforcement, keeping walls, embankment stabilization, and slope protection. With magnificent chemical resistance, UV durability, and long-term performance, it ensures dependable consequences even in harsh environmental conditions, making it an perfect and not pricey answer for present day civil engineering and geotechnical projects.

1. HDPE Geogrid Material Characteristics

1.1 High-Quality HDPE Resin

The HDPE geo grid mesh is manufactured the use of premium-grade high-density polyethylene (HDPE), regarded for its terrific toughness, flexibility, and influence resistance. This top notch resin ensures uniform performance, tremendous processability all through extrusion and stretching, and long-lasting electricity even underneath heavy load conditions.

1.2 UV and Weather Resistance

The fabric is particularly formulated with anti-UV components and stabilizers to stand up to long-term publicity to daylight and excessive weather conditions. It keeps its structural integrity and mechanical homes beneath excessive temperatures, freezing conditions, and extended outside use, making sure reliable overall performance in a vast vary of environments.

1.3 Chemical Stability

HDPE provides greatest resistance to acids, alkalis, and salts, making the geogrid retaining wall appropriate for use in chemically aggressive or contaminated soils. Its inert nature prevents degradation or corrosion, making sure long-term chemical steadiness in functions such as landfills, coastal structures, and industrial foundations.

1.4 High Tensile Strength and Low Creep

Through specific stretching and molecular orientation, the HDPE geogrid mesh achieves remarkable tensile power and minimal deformation below non-stop load. Its low creep traits warranty sustained reinforcement overall performance over the lifespan of the structure, even below consistent stress or dynamic loading conditions.

2. HDPE Geogrid Structure and Design

GEOSINCERE HDPE Geogrids are designed in uniaxial, biaxial, and triaxial configurations, every developed to meet the precise needs of current geotechnical and civil engineering projects. These structural versions permit for top-quality overall performance in soil reinforcement, load distribution, and slope balance applications.

2.1 Uniaxial Geogrid

The HDPE uniaxial geogrid presents tremendously excessive tensile electricity in a single direction, making it perfect for functions that require reinforcement towards heavy masses or lateral soil pressure. Commonly used in preserving walls, steep slopes, and embankment reinforcement, it successfully enhances soil balance with the aid of permitting robust interlocking and stress switch between the soil and the grid ribs. Its elongated aperture diagram optimizes load-bearing ability and reduces deformation underneath non-stop stress.

2.2 Biaxial Geogrid

The HDPE biaxial geogrid points balanced tensile electricity in each longitudinal and transverse directions, imparting amazing load distribution and floor stabilization. It is extensively utilized in avenue base construction, pavement reinforcement, and railway subgrade stabilization the place uniform power is required. The rectangular mesh shape correctly distributes utilized loads, minimizes rutting and cracking, and extends the carrier existence of roads and foundations.

2.3 Triaxial Geogrid

The triaxial geogrid accommodates a multi-directional triangular mesh pattern, designed to supply best 360° load-bearing and reinforcement capability. This superior diagram enhances interlocking with combination materials, making sure wonderful balance underneath dynamic or uneven loading conditions. It is specially appropriate for smooth soil areas, heavy-duty pavements, and complicated terrain initiatives the place multi-directional stress manage is essential.

2.4 Manufacturing Process

Each geo grid ground grid kind is produced via a particular extrusion–punching–stretching process, which ensures regular aperture size, excessive tensile performance, and incredible dimensional stability. The ensuing uniform mesh shape maximizes soil interlocking efficiency, enhances load transfer, and ensures long-term mechanical integrity, even in annoying building environments.

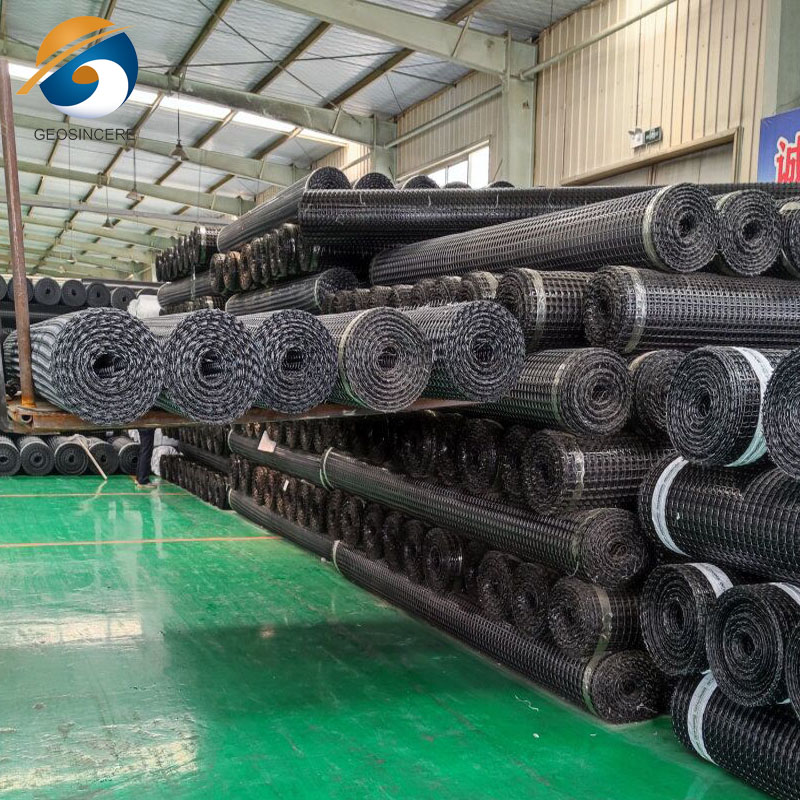

3. GEOSINCERE Geosynthetics HDPE Geogrid Manufacturing Excellence

GEOSINCERE Geosynthetics makes use of trendy computerized extrusion and stretching tools to produce high-performance HDPE geogrid mesh retaining wall with exquisite consistency and precision. Every step of the manufacturing procedure — from uncooked fabric choice to closing satisfactory inspection — is performed below strict technical supervision to warranty most fulfilling product uniformity, dimensional accuracy, and mechanical reliability.

3.1 Precision Engineering

Each manufacturing batch undergoes meticulous monitoring and checking out for key parameters such as thickness, tensile modulus, elongation, and weight per unit area. Advanced trying out units make certain that each roll of geogrid material meets or exceeds global standards. This precision engineering strategy ensures secure tensile performance, uniform aperture geometry, and long-term sturdiness throughout all product grades.

3.2 Automated Control Systems

GEOSINCERE’s contemporary manufacturing strains are geared up with wholly computerized manage and comments systems, enabling non-stop monitoring of temperature, stretching ratio, and material flow. These computerized structures assurance constant product quality, limit human error, and hold manufacturing effectivity and repeatability. This excessive degree of automation lets in for unique manipulate over plastic geogrid uniformity, making sure most effective interlocking overall performance in each undertaking application.

3.3 Customized Options

Understanding that each challenge has special engineering requirements, GEOSINCERE presents a large vary of customization options. Mesh aperture size, roll width, tensile strength, and elongation traits can all be tailor-made to precise format needs. Custom manufacturing allows the geogrid erosion control to combine seamlessly with a number of soil types, load conditions, and structural configurations, turning in project-specific reinforcement options for roads, slopes, holding structures, and foundations.

4. HDPE Geogrid Technical Properties

4.1 Tensile Strength

The HDPE geogrid soil stabilization affords a large tensile power vary from 20 to 200 kN/m, relying on whether or not it is uniaxial, biaxial, or triaxial. This choicest tensile ability lets in it to efficaciously withstand excessive stresses and distribute hundreds throughout massive soil areas. The high-strength grid ribs make sure fantastic load switch and soil confinement, making it best for purposes such as holding walls, embankments, and basis stabilization.

4.2 Elongation at Break

With an elongation at wreck normally ≤13%, the HDPE geo grid driveway famous low deformation and excessive dimensional steadiness beneath tension. This low elongation behavior ensures regular structural reinforcement, lowering the chance of agreement and floor cracking over time. It gives long-term reliability, even beneath cyclic or dynamic loading stipulations often encountered in avenue and railway applications.

4.3 Chemical Resistance

Manufactured from chemically inert high-density polyethylene, the retaining wall grid demonstrates super resistance to acids, alkalis, salts, and different corrosive agents. It keeps its bodily and mechanical homes even when uncovered to aggressive soil or groundwater conditions, making sure long-term steadiness in functions such as landfills, coastal structures, and industrial sites.

4.4 Temperature Range

The HDPE gravel geogrid provides secure overall performance throughout a large temperature spectrum, usually ranging from -60°C to +60°C. It resists thermal expansion, contraction, and cloth brittleness in each extraordinarily bloodless and warm climates. This function ensures reliable performance and sturdiness in difficult environments, inclusive of desolate tract areas and subarctic building sites.

4.5 UV Resistance

Formulated with anti-UV stabilizers and oxidation inhibitors, the HDPE geogrid slope stabilization offers awesome resistance to ultraviolet degradation and long-term outside exposure. Even underneath non-stop sunlight, it retains its tensile power and structural integrity, making it best for open-air installations such as slopes, embankments, and street foundations.

5. HDPE Geogrid Key Performance Advantages

5.1 Enhanced Soil Reinforcement

The HDPE geogrid wall appreciably improves the load-bearing potential of vulnerable or unstable soils by way of presenting a secure reinforcement layer that distributes utilized hundreds uniformly. Its inflexible grid shape varieties sturdy interlocking with soil or mixture particles, decreasing displacement and deformation underneath heavy loads. This consequences in larger stability, multiplied shear strength, and extended long-term overall performance for roads, embankments, and holding structures.

5.2 Erosion and Slip Prevention

With its excessive tensile energy and interlocking design, the HDPE retaining wall geo grid presents high quality erosion manipulate and slope stabilization. It prevents floor soil erosion, slip failures, and settlement, mainly on steep embankments and riverbanks. When blended with geotextiles or vegetation, it offers a complete soil safety system, making sure the integrity of slopes and earth constructions even underneath heavy rainfall or water go with the flow conditions.

5.3 Cost-Effective Construction

By reinforcing the soil and growing its bearing strength, the HDPE erosion control geogrid lets in for a discount in the thickness of mixture layers or different base materials. This no longer solely minimizes fabric consumption however additionally reduces transportation, set up time, and standard undertaking costs. Its lengthy provider existence in addition contributes to decrease upkeep expenses, making it a affordable answer for large-scale infrastructure and civil works.

5.4 Long Service Life

Engineered from high-density polyethylene with gorgeous resistance to UV radiation, oxidation, and chemicals, the HDPE biaxial plastic geogrid provides long-lasting overall performance in the most worrying environments. It keeps its structural integrity and mechanical energy for decades, even beneath consistent load or harsh climatic conditions. This ensures sustained reinforcement and minimal want for restore or alternative over the undertaking lifespan.

5.5 Eco-Friendly Solution

Lightweight and effortless to transport, the HDPE geogrid landscaping reduces gasoline consumption and lowers the carbon footprint at some point of transport and installation. Its potential to reduce the use of herbal aggregates contributes to aid conservation and sustainable building practices. Additionally, it is one hundred percent recyclable, aligning with modern-day environmental requirements and inexperienced infrastructure initiatives.

Conclusion

The HDPE Geogrid via GEOSINCERE Geosynthetics represents a ideal aggregate of strength, durability, and sustainability. Its superior sketch and tested overall performance make it an indispensable factor in present day geotechnical engineering.

By selecting Shandong Geosino New Material Co.,Ltd(GEOSINCERE Geosynthetics), you obtain a depended on companion committed to innovation, quality, and environmental accountability — turning in geosynthetic options that construct a superior and greater sustainable future.