Uniaxial Plastic Geogrid Erosion Control for Retaining Wall

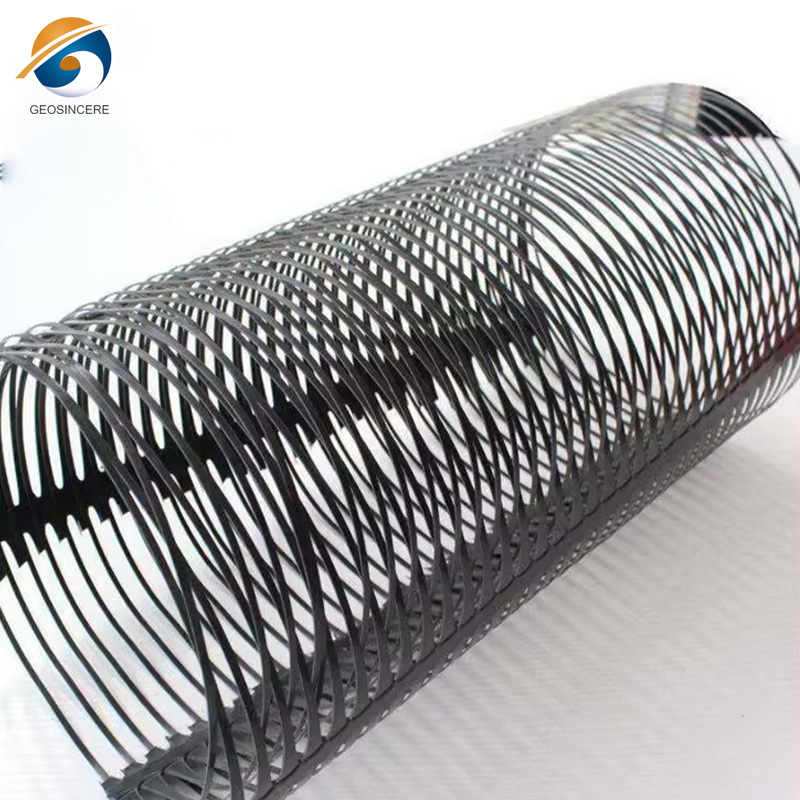

Uniaxial Plastic Geogrid Erosion Control for Retaining Wall is a specially designed geosynthetic material used to enhance the stability and erosion resistance of retaining walls. The geogrid is made from high-strength plastic polymers, which provide excellent tensile strength and durability.

The uniaxial design of the geogrid means that it has higher strength in one direction, making it ideal for stabilizing soil and preventing erosion in retaining wall applications. The geogrid is typically installed horizontally within the soil layers behind the retaining wall, creating a reinforced soil structure.

The Uniaxial Plastic Geogrid Erosion Control for Retaining Wall is a reliable and effective solution for enhancing the stability and erosion resistance of retaining walls, providing long-term protection against soil movement and erosion.

Uniaxial plastic geogrids have become essential in modern civil engineering, particularly in erosion control and reinforced soil retaining walls. These geosynthetic materials enhance structural stability, improve load distribution, and significantly extend the service life of earth-retaining systems.

This article offers an in-depth technical exploration of uniaxial plastic geogrids, focusing on their function in erosion control and their integration in retaining wall systems. The content adheres to international engineering standards and is optimized for both decision-makers and site engineers.

Table of Contents

What Is a Uniaxial Plastic Geogrid?

Engineering Principles in Retaining Wall Stabilization

Erosion Control Mechanism Using Geogrids

Material Properties and Technical Specifications

Installation Guidelines for Retaining Walls

Industry Standards and Regulatory Compliance

Performance Examples and Case Applications

Frequently Asked Questions (FAQs)

Sourcing and Supplier Checklist

Final Thoughts and Professional Recommendation

1. What Is a Uniaxial Plastic Geogrid?

A uniaxial plastic geogrid is a polymer-based, high-tensile geosynthetic material manufactured by stretching a punched sheet of HDPE (high-density polyethylene) or PP (polypropylene) in one direction—usually the machine direction. This results in a strong, stiff structure with high tensile strength in a single axis, ideal for reinforcing soil structures subjected to lateral earth pressures.

🔧 Primary applications: Retaining walls, steep slopes, embankments, and load-bearing structures

2. Engineering Principles in Retaining Wall Stabilization

Retaining walls experience active earth pressure, overturning moments, and shear loads—especially under rainfall or seismic conditions. Incorporating uniaxial plastic geogrids transforms the soil-geogrid mass into a composite system, significantly increasing internal stability and resistance to sliding and pullout.

Structural Roles:

Improve factor of safety (FS > 1.5 typically required)

Prevent lateral soil movement and wall deformation

Distribute vertical and surcharge loads more uniformly

3. Erosion Control Mechanism Using Geogrids

Uniaxial geogrids also act as erosion control stabilizers, particularly in:

Cut-and-fill slopes

Backfill transitions

Toe of wall drainage zones

By reinforcing the topsoil and acting as a mechanical anchor, geogrids:

Prevent topsoil washout

Maintain vegetative cover

Reduce sediment transport

Increase resistance to rain-induced shear failure

4. Material Properties and Technical Specifications

| Property | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength (MD) | 40–200 kN/m | ASTM D6637 (Method B) |

| Elongation at Yield | <10% | ISO 10319 |

| Aperture Size | 25–65 mm | Manufacturer Spec |

| Polymer Type | HDPE / PP with UV Stabilizer | ASTM D4218 (carbon black) |

| Creep Resistance | >10,000 hours | ASTM D5262 |

| Durability / Service Life | >75 years (buried conditions) | ISO/TR 20432 |

5. Installation Guidelines for Retaining Walls

Step-by-Step Overview:

Site Preparation: Excavate wall footprint and compact subgrade

Base Layer: Lay gravel or crushed stone bedding (≥150 mm)

Geogrid Placement: Lay geogrid in horizontal layers at design spacing (typically 0.5–1.0 m)

Embedment: Extend geogrid back into the retained soil (length L = 0.7–1.0 × wall height)

Facing Connection: Wrap or mechanically fix geogrid to the retaining wall blocks or panels

Backfilling: Compact soil in lifts of 200–300 mm to 95% Proctor density

Drainage: Install filter fabric and perforated pipe at wall toe

🏗 Tip: Do not roll heavy compaction equipment directly over unconfined geogrid sections.

6. Industry Standards and Regulatory Compliance

Compliance ensures long-term performance and safety. Key standards include:

| Standard / Guideline | Scope |

|---|---|

| ASTM D6637 / D5262 | Tensile strength and creep testing |

| ISO 10319 | Wide-width tensile properties |

| AASHTO M288 | Geosynthetic classification |

| EN 13250 / EN 13738 | Durability and mechanical strength (EU) |

| FHWA-NHI-07-092 | Soil reinforcement design (USA) |

| BS 8006-1:2010 | Reinforced soil design and construction |

7. Performance Examples and Case Applications

✅ Case: 6m-high Modular Block Wall in Coastal Zone

Challenge: Erosion from seasonal rains and weak sandy backfill

Solution: 3 layers of 100 kN/m HDPE geogrid spaced at 0.75 m intervals

Outcome: No movement after 4 years, vegetation successfully grown over face

✅ Case: Slope Reinforcement Near Railway Embankment

Geogrid prevented slip failures during heavy rainfall

Reduced need for retaining walls by 25%

8. Frequently Asked Questions (FAQs)

Q1: What’s the difference between uniaxial and biaxial geogrids?

Uniaxial geogrids offer high tensile strength in one direction, perfect for wall reinforcement. Biaxial geogrids have balanced strength in two directions and are better for ground stabilization.

Q2: Can I install geogrid with timber or gabion retaining walls?

Yes. Proper mechanical connection or embedment is critical for performance, regardless of the wall type.

Q3: What’s the lifespan of plastic geogrids in soil?

Typically exceeds 75 years, provided they are UV-protected and buried under sufficient soil cover.

Q4: How do I determine spacing and length of geogrid layers?

A geotechnical engineer should perform stability analysis using parameters like soil cohesion, angle of friction, wall height, and surcharge loads.

9. Sourcing and Supplier Checklist

Before placing an order, ensure the geogrid supplier provides:

✅ Product data sheet with tensile strength, creep curve, aperture size

✅ Test reports from accredited labs (ASTM, ISO)

✅ Guidance for layer spacing and installation

✅ Compliance with ASTM D6637 / AASHTO M288 / ISO 10319

✅ Compatibility with retaining wall system or slope angle

📥 This site provides technical support, customization, and material consultation based on project load requirements and environmental conditions.

10. Final Thoughts and Professional Recommendation

Using uniaxial plastic geogrid for erosion control in retaining walls is a proven, engineered solution that ensures long-term stability and resilience. It helps prevent structural failure, reduces maintenance costs, and improves safety in high-risk areas like slopes and coastal zones.

🛠 When properly designed and installed, geogrid-reinforced retaining structures offer a 3–5x improvement in load-bearing capacity and erosion resistance.

✅ Request Technical Consultation or Quote

This site offers:

Engineering-grade geogrids in various strengths (40–200 kN/m)

Compliance with ISO, ASTM, AASHTO, and EN standards

Design support and installation guides

Bulk pricing and international shipping

📩 Contact us today for a free engineering consultation or to receive project-specific pricing and geogrid specifications.

Parameter

Properties | BGUG 25 | BGUG 35 | BGUG 50 | BGUG 80 | BGUG 110 | BGUG 120 | BGUG 150 | |

Width(mm) | 1100 | |||||||

Length /roll (m) | 50 | |||||||

Yield strength ≥kN/M | HDPE | 25 | 35 | 50 | 80 | 110 | 120 | 150 |

PP | 25 | 35 | 50 | 80 | 110 | 120 | 150 | |

Elongation | HDPE (%) | 11-16 | ||||||

PP≤ (%) | 10 | |||||||

Strength at 2% elongation ≥kN/M | HDPE | 6 | 9 | 10 | 23 | 30 | 35 | 46 |

PP | 7 | 10 | 12 | 26 | 32 | 38 | 48 | |

Strength at 5% elongation ≥kN/M | HDPE | 12 | 18 | 25 | 44 | 60 | 70 | 87 |

PP | 14 | 20 | 28 | 48 | 64 | 75 | 93 | |

Uniaxial Plastic Geogrid Erosion Control for Retaining Wall Features

Applications of Uniaxial Plastic Geogrid Erosion Control for Retaining Wall