Anti Seepage HDPE Composite Geomembrane for Tailing Bottom

Technical Parameters and Specifications

Raw Material: Virgin HDPE resin, geotextile (PET/PP nonwoven)

Thickness Range: 1.0–3.0 mm (HDPE base)

Composite Strength: ≥ 20–40 kN/m (based on GSM)

Puncture Resistance: ≥ 1,500–3,500 N

Tear Resistance: ≥ 350–650 N

Permeability Coefficient: ≤ 1.0 × 10⁻¹⁴ cm/s

Carbon Black Content: 2–3% (anti-UV)

Weld Type: Hot wedge welding / extrusion welding

Standards: GRI-GM13, ASTM D6693, ISO 10319

Product Definition

The Anti Seepage HDPE Composite Geomembrane for Tailing Bottom is a multi-layer geosynthetic barrier combining high-density polyethylene with reinforced geotextiles to deliver long-term containment, chemical resistance, and anti-permeation performance for mining tailing ponds, waste dams, and heavy-load industrial reservoirs.

Technical Parameters and Specifications

Raw Material: Virgin HDPE resin, geotextile (PET/PP nonwoven)

Thickness Range: 1.0–3.0 mm (HDPE base)

Composite Strength: ≥ 20–40 kN/m (based on GSM)

Puncture Resistance: ≥ 1,500–3,500 N

Tear Resistance: ≥ 350–650 N

Permeability Coefficient: ≤ 1.0 × 10⁻¹⁴ cm/s

Carbon Black Content: 2–3% (anti-UV)

Weld Type: Hot wedge welding / extrusion welding

Standards: GRI-GM13, ASTM D6693, ISO 10319

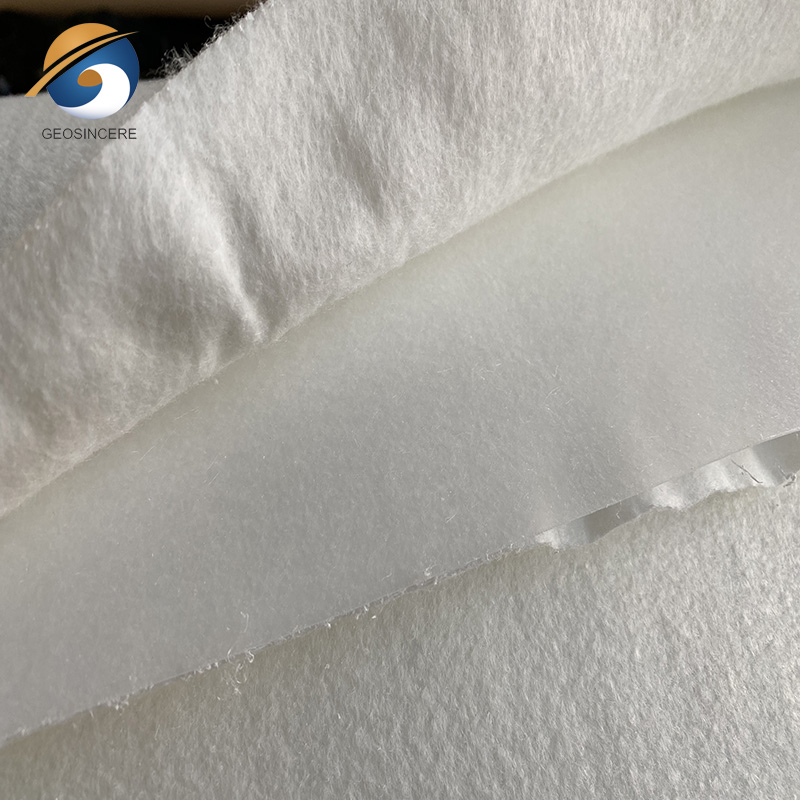

Structure and Material Composition

HDPE Base Layer: Primary impermeable barrier with high tensile strength and chemical resistance.

Reinforced Geotextile Layer: Needle-punched PET/PP providing drainage, flexibility, and puncture resistance.

Thermal Bonding Interface: Ensures long-term lamination integrity under heavy load.

Surface Treatment: Either smooth or textured (improved friction on slopes).

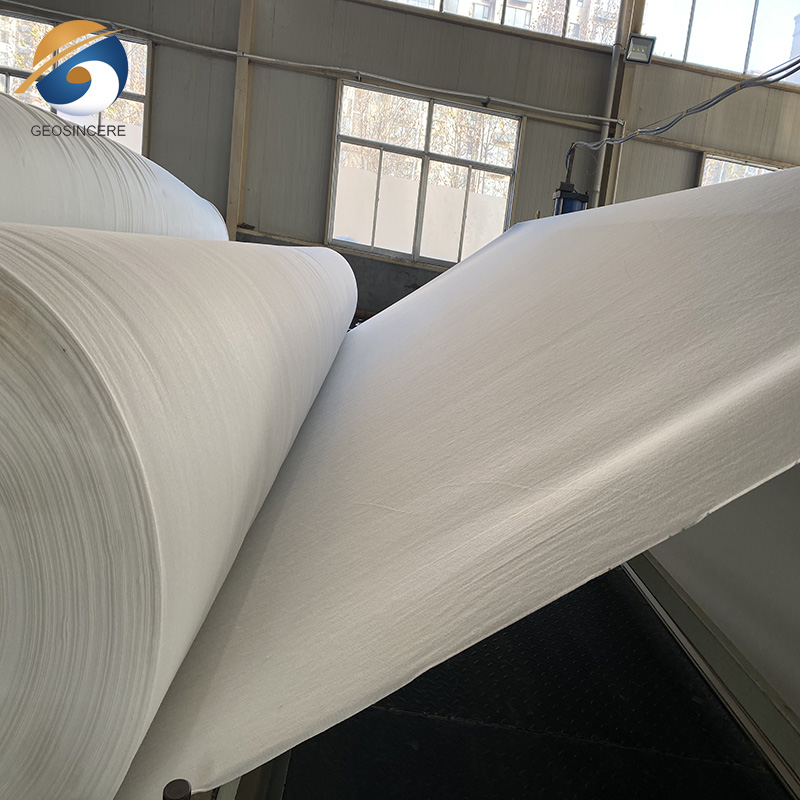

Manufacturing Process (Engineering Workflow)

Resin Drying & Filtration: HDPE pellets filtered for impurities to guarantee uniform melt flow index.

Extrusion Film Forming: HDPE melted at 210–240°C and extruded through a flat die to controlled thickness.

Calendering & Cooling: Film cooled by steel rollers to stabilize mechanical properties.

Geotextile Bonding: HDPE film laminated with nonwoven PET/PP via hot pressing or glue bonding.

Texturing (Optional): Roller embossing for anti-slip surface used in steep-slope tailing dams.

Automatic Edge Trimming & Winding: Rolls formed under tension control to avoid wrinkles.

Quality Testing: Tensile, tear, puncture, permeability and oxidation induction time (OIT) tests.

Industry Comparison

| Material | Permeability | Chemical Resistance | Cost | Typical Use |

|---|---|---|---|---|

| HDPE Composite Geomembrane | Very Low | Excellent | Medium | Tailing bottom, waste dams |

| Clay Liner (GCL) | Low | Medium | Medium-High | Landfill covers |

| PVC Geomembrane | Medium | Medium | Low | Agricultural ponds |

| EPDM Rubber Sheet | Medium | High | High | Water features |

Application Scenarios

Mining tailing pond bottom lining

Mineral processing slurry containment

Heap leaching pads

Industrial wastewater lagoons

Hazardous chemical containment areas

EPC contractor multi-layer barrier systems

Core Pain Points and Solutions

Pain Point 1: Long-term chemical attack from acidic tailings.

Solution: HDPE resin with high OIT and 3% carbon black for improved oxidative resistance.Pain Point 2: Puncture from sharp waste rock.

Solution: Composite structure with 400–800 GSM geotextile to buffer impact forces.Pain Point 3: Installation damage during welding.

Solution: On-site ASTM D6392 welding tests + double-track seam verification.Pain Point 4: Slippage on slopes and embankments.

Solution: Textured geomembrane + friction angle ≥ 28–32°.

Risk Warnings and Mitigation Measures

Risk: Subgrade irregularity causing geomembrane stretching.

Mitigation: Require 95% compaction and debris removal before installation.Risk: UV degradation on unburied sections.

Mitigation: Use 2–3% carbon black + cover soil within 30 days.Risk: Weld seam failure due to low temperature.

Mitigation: Maintain welding temperature 350–450°C depending on thickness.Risk: Chemical incompatibility with certain leachates.

Mitigation: Perform compatibility testing per EPA Method 9090.

Procurement and Selection Guide

Determine HDPE thickness: 1.5–2.0 mm for standard tailings; 2.5–3.0 mm for high-load mining dams.

Choose geotextile GSM: 400–800 GSM based on puncture and slope stability requirements.

Check compliance certifications: GRI-GM13, ISO tensile tests, OIT test reports.

Specify surface type: Smooth for flat areas, textured for slopes and embankments.

Require double-track weld seam testing before mass deployment.

Verify supplier capacity: width up to 8 m, automatic extrusion lines, QA lab.

Assess logistics: roll weight, container loading density, and on-site unrolling equipment compatibility.

Engineering Case Example

A mining EPC contractor used 2.0 mm Anti Seepage HDPE Composite Geomembrane for a 1.8-million-m² tailing pond bottom in a copper mine. The composite 600 GSM geotextile layer reduced installation puncture incidents by 42%, while textured HDPE improved slope stability by 30%. Post-operation monitoring over 24 months recorded no measurable leakage, meeting the mine safety authority’s containment requirements.

FAQ

1. What thickness is recommended for tailing bottom? Typically 1.5–2.5 mm depending on load and chemical exposure.

2. Can HDPE composite geomembrane resist acidic tailings? Yes, HDPE offers excellent chemical resistance to acids, alkalis, and salts.

3. Is textured geomembrane necessary? Yes for slopes; it increases friction and prevents slippage.

4. What welding method is recommended? Hot wedge welding is preferred for consistency and speed.

5. How long can it be exposed to sunlight? Short-term only; long-term exposure requires covering.

6. Can it be used with GCL? Yes, composite barrier systems are common in mining containment.

7. What is the typical roll width? 5–8 meters depending on production line.

8. How to test weld seam strength? ASTM D6392 shear and peel testing.

9. Is composite geomembrane better than single-layer HDPE? It offers improved puncture resistance and stability.

10. Can it handle high temperatures? Suitable for continuous service at −40°C to 60°C.

11. Does geotextile affect anti-seepage performance? No; HDPE provides impermeability, geotextile provides mechanical protection.

CTA: Request Quotation or Technical Files

For project specifications, MSDS files, ASTM test reports, or engineering samples of Anti Seepage HDPE Composite Geomembrane for Tailing Bottom, contact our technical sales department. We provide EPC-level design support, tailored thickness recommendations, and optimized container-loading solutions for large mining projects.

E-E-A-T Author Credentials

Written by a senior geosynthetics engineering consultant with 12+ years of field experience in mining containment design, geomembrane QC testing, and large-scale EPC deployment support.

Referenced institutions: Geosynthetic Institute (GSI), International Geosynthetics Society (IGS).