Geo Geocell

Manufacturing Process and Engineering Control

Standard Manufacturing Workflow

HDPE resin selection and compounding with stabilizers

Flat strip extrusion with thickness calibration

Surface embossing or texturing (if required)

Precision ultrasonic welding at programmed intervals

Panel expansion testing and weld integrity inspection

Cutting, folding, and packaging for transportation

Key Manufacturing Equipment

Polymer extrusion lines

Ultrasonic welding systems

Automated punching and cutting machines

Tensile and peel strength testing equipment

Environmental aging and UV resistance testers

Product Definition of Geo Geocell

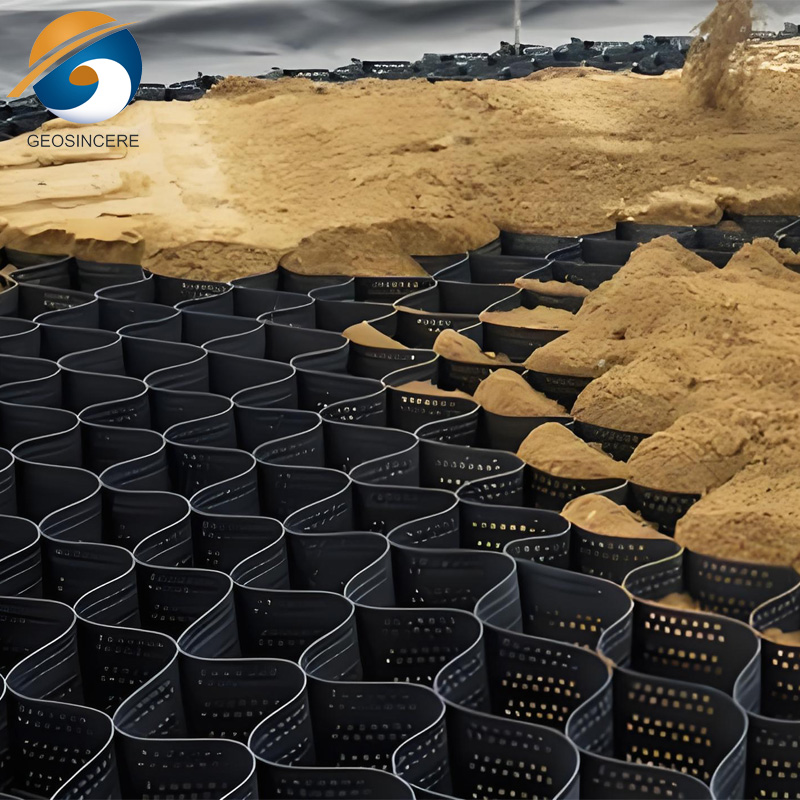

Geo Geocell is a three-dimensional cellular confinement system manufactured from high-strength polymer strips, ultrasonically welded to form an expandable honeycomb structure. When infilled with soil, aggregate, or concrete, it provides lateral confinement, load distribution, and long-term stabilization for earthworks and infrastructure engineering.

Technical Parameters and Specifications

Geo Geocell systems are engineered to meet civil, transportation, and environmental project requirements under international geosynthetics standards.

| Parameter | Typical Specification |

|---|---|

| Material | High Density Polyethylene (HDPE) |

| Strip Thickness | 1.1 mm – 1.8 mm |

| Cell Height | 50 mm – 300 mm |

| Cell Size (Expanded) | 200 × 200 mm / 250 × 250 mm |

| Tensile Strength | ≥ 20 MPa |

| Weld Peel Strength | ≥ 1,000 N |

| Carbon Black Content | 2.0% – 2.5% |

| Service Temperature | -40°C to +80°C |

| Design Service Life | ≥ 50 years (buried conditions) |

Structure and Material Composition

Geo Geocell derives its engineering performance from a carefully designed structural configuration.

HDPE Geocell Strips: Provide flexibility, chemical resistance, and tensile capacity

Ultrasonic Weld Nodes: Ensure uniform load transfer between adjacent cells

Honeycomb Geometry: Creates three-dimensional confinement and shear resistance

Surface Texture: Smooth or textured options to enhance soil–polymer interaction

Anchoring Interfaces: Allow mechanical anchoring for slope and channel stabilization

Manufacturing Process and Engineering Control

Standard Manufacturing Workflow

HDPE resin selection and compounding with stabilizers

Flat strip extrusion with thickness calibration

Surface embossing or texturing (if required)

Precision ultrasonic welding at programmed intervals

Panel expansion testing and weld integrity inspection

Cutting, folding, and packaging for transportation

Key Manufacturing Equipment

Polymer extrusion lines

Ultrasonic welding systems

Automated punching and cutting machines

Tensile and peel strength testing equipment

Environmental aging and UV resistance testers

Industry Comparison

Geo Geocell is often evaluated against alternative ground stabilization and slope protection systems.

| Criteria | Geo Geocell | Geogrid | Riprap / Gabion |

|---|---|---|---|

| Structural Form | 3D cellular confinement | 2D planar reinforcement | Mass gravity system |

| Load Distribution | Excellent | Moderate | Limited |

| Material Consumption | Low | Low | High |

| Installation Speed | Fast | Fast | Slow |

| Environmental Adaptability | High | Medium | Low |

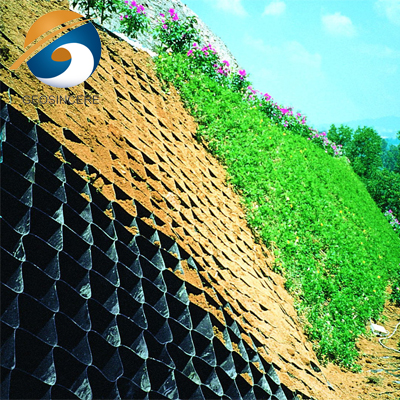

Application Scenarios

Geo Geocell is widely adopted by distributors, EPC contractors, and engineering firms across multiple sectors.

Road base and subgrade reinforcement

Railway embankment stabilization

Slope protection and erosion control

Channel lining and hydraulic engineering

Load support for parking areas and access roads

Land reclamation and soft soil improvement

Core Engineering Pain Points and Solutions

Weak subgrade bearing capacity: 3D confinement increases composite modulus

Slope erosion under rainfall: Cellular structure reduces surface runoff velocity

Material migration: Cell walls prevent lateral displacement of infill

High construction cost: Reduced fill thickness and faster installation

Risk Warnings and Mitigation Recommendations

Incorrect anchoring may reduce slope performance

Improper infill selection can limit confinement effect

UV exposure requires timely covering or backfilling

Weld damage during installation must be avoided

Design calculations should follow project-specific loading

Procurement and Selection Guide

Define application type: slope, road, channel, or foundation

Select appropriate cell height based on load and soil conditions

Confirm strip thickness and weld strength requirements

Evaluate material certification and testing reports

Assess supplier production capacity and quality control

Request samples for expansion and weld testing

Verify compliance with local engineering standards

Engineering Application Case

In a highway embankment project with soft clay subgrade, Geo Geocell panels with 150 mm cell height were installed over a granular base layer. After infilling and compaction, plate load testing showed a significant increase in bearing capacity and reduced post-construction settlement compared with untreated sections.

FAQ: Geo Geocell

What is the primary function of Geo Geocell? To provide three-dimensional soil confinement.

Is Geo Geocell suitable for slopes? Yes, particularly for erosion control and stabilization.

What infill materials are recommended? Sand, gravel, soil, or concrete depending on use.

How is it installed? Expanded on-site, anchored, infilled, and compacted.

Can it be used underwater? Yes, with appropriate installation methods.

What is the expected service life? Typically over 50 years when buried.

Is UV resistance important? Yes, especially before backfilling.

Can Geo Geocell replace traditional retaining structures? In many low to medium load cases, yes.

Does it require heavy equipment? Minimal equipment compared to rigid systems.

Is design calculation necessary? Yes, for critical infrastructure projects.

Request Quotation or Technical Documentation

For project-based pricing, detailed technical datasheets, or engineering samples of Geo Geocell systems, procurement teams and engineering consultants are encouraged to submit formal requests.

E-E-A-T: Authoritative Technical Background

This article is prepared by professionals specializing in geosynthetics engineering, infrastructure design, and international project supply, ensuring technically accurate and procurement-oriented information for B2B decision-makers.