What is 8 oz Geotextile Fabric?

Perhaps, when involved in a landscaping, construction, or civil engineering project, you might have come across the term "geotextile fabric" and how important it is for the project. Different weights and types of this fabric exist, but 8 oz geotextile fabric is the one that is versatile and thus heavily used. So, what exactly is it and why is it so often that it gets specified? We detail all aspects of 8 oz geotextile fabric in this thorough article. Besides, we will also elaborate on its main uses and advantages, and lastly, we will give you a step-by-step installation guide to make sure your project turns out to be a success.

1. 8 oz Geotextile Fabric Understanding the Basics: What Does "8oz" Mean?

Before talking about the fabric itself, it makes sense to understand what the "8 oz" specification means.The term "8 oz" refers to the fabric's weight per square yard. This non woven geotextile is generally made of polypropylene fibers that are needle-punched together for creating a strong felt-like mat. This manufacturing method produces thick, permeable fabric which can be used for separation, filtration, drainage, and light stabilization.

Simply put, if a perfectly square yard measuring 3 feet by 3 feet is cut from the geotextile fabric and weighed, its approximate weight would be 8 ounces. Here, the weight stands for a strong and durable material, which is thicker than the light variants (e.g. 4 oz or 6 oz) but more flexible and economical than heavy ones (e.g., 10 oz or 16 oz). So, the 8 oz non woven geotextile fabric is an excellent middle ground in terms of strength, permeability, and the convenience of handling.

2. Key Uses and Applications of 8 oz Geotextile Fabric

8 oz geotextile fabric is a very versatile product. Its most important functionalities in engineering work are that it is used for separation, filtration, and drainage. Here are the areas of its applications:

2.1 Beneath Gravel Driveways and Walkways

This is probably its most popular use. The non woven geotextile fabric 8 oz is spread over the compacted subsoil prior to the addition of gravel. It does a wonderful job in separating gravel from soil, thus, over time, the stones will not have a chance to sink into the mud. The result is that not only, the structural integrity of your driveway will be maintained, but also, it will be less rutted and less gravel will need to be added at a later time.

2.2 Under Paver Patios and Retaining Walls

In the case of patios and retaining wall foundations, the geotextile fabric 8 oz can be seen as a stable separation layer. By separating the sand or gravel base layer from the clay or soil underneath, it eliminates the problem of the base settling and shifting. Also, it facilitates water drainage, which leads to a lesser hydrostatic pressure at the back of the retaining walls.

2.3 French Drains and Drainage Systems

A significant role here is played by the 8 oz non woven geotextile's superior filtration properties. When a perforated pipe, which is surrounded by gravel, is in a trench, the 8 oz nonwoven geotextile fabric is used as a filter. Water will receive its free passage through the drain, but soil particles are blocked from moving into the gravel or pipe, thus pipes do get clogged and the problem is "piping."

2.4 Erosion Control on Slopes

Putting the 8 oz filter fabric on slopes and then covering it with either soil or mulch will contribute to soil being loosely held and at the same time, as new roots start growing, the place gets stabilized. It significantly reduces soil erosion through wind and rain so it is an excellent solution for embankments, shorelines, and land that has just been graded.

2.5 Landscape and Garden Beds

As a weed barrier, it starves weeds of light thus suppressing their growth while letting air and water reach plant roots. 8 oz non woven geotextile filter fabric doesn't decay and create new impermeable layers which make it bad for the soil health as plastic does.

2.6 Soil Stabilization for Temporary Access Roads

At construction sites, 8 oz geotextile is sometimes laid over marshy ground to create a stable working platform for vehicles and machinery. This way, the load is spread and the ground does not become a sticky mud pit.

3. 8 oz Geotextile Fabric The Major Benefits: Why Choose an 8 oz Weight?

What are the reasons for 8 oz selection rather than other alternatives? The advantages come from the physical characteristics of the fabric:

3.1 Durability and Puncture Resistance

The 8oz weight provides the fabric with high tensile strength and puncture resistance. It will not rip even after a heavy load of gravel and if an occasional sharp stone pits it, strong enough for a long time.

3.2 Excellent Water Permeability

Due to its non-woven, needle-punched nature, the 8 oz needle punch filter fabric gets to have millions of micro-pores. This affords a very high rate of vertical water flow, which is very necessary for drainage and for instance, preventing the roots from being drowned.

3.3 Effective Separation and Filtration

Non woven geotextile fabric 8 oz effectively separates different soil layers and at the same time filters out the finest clay particles while letting water through (filtration) thus it can easily do both tasks at high load levels.

3.4 UV Resistance

A product that has been ultraviolet stabled will be able to endure the sun's rays for a reasonable number of days (usually 30-90 days, depending on the product) and will not be too seriously damaged by exposure before being covered.

3.5 Cost-Effectiveness

For a wide range of residential and commercial applications, the fabric geotextile is a winner in terms of the performance-to-cost ratio. The weight is sufficient to handle work that is demanding without going into the higher expense area of heavy industrial-grade non woven geotextile fabric.

4. A Step-by-Step Installation Guide for 8 oz Geotextile Fabric

It is through the correct installation of geo fabric that all its benefits can be fully realized. The following is the correct way of doing it.

8 oz Geotextile Fabric Materials & Tools Needed:

8 oz geotextile fabric (rolls)

Utility knife or scissors

Landscape staples (6-inch or longer)

Tape measure

Gloves

Overlap tape (optional, for critical seams)

Step 1: Site Preparation

Firstly, clear the site of any rubbish, chiselled rocks, twigs, and plants. In the case of a driveway, the subsoil should be graded and compacted to the required level and curve. It is highly recommended that the base be very compacted and also smooth.

Step 2: Calculate and Roll Out the Fabric

Take measurements of your surface and lay the non woven geotextile out over the ground that has been prepared. The manufacturer usually indicates the roll direction as the direction of maximum strength; therefore orient the roll in such a way that the strongest direction is at right angles to the main traffic or point of stress (e.g., across the driveway not down the length of it).

Step 3: Overlap the Seams

If you want an uninterrupted surface, you have to overlap the edges of the two rolls. A usual practice is that the overlap should be from 12 to 18 inches at the very least. For places where there is a lot of stress like in driveways, some experts suggest that the overlap should be as much as 3 feet. If the seam is of utmost importance, you can use special geotextile tape to join the two layers and thus prevent them from shifting.

Step 4: Secure the 8 oz Geotextile Fabric

Consider using one of these methods, such as landscape staples, to always hold the geofabric down on the top of the ground. Note the use of these on slopes or when there is wind. You may place the staples anywhere from 3-5 feet apart along edges and seams. Do not stretch the fabric; instead, perform it flat and let it take the shape of the ground.

Step 5: Cover Immediately

One of the ways to counter the UV degradation of your geotextile drainage fabric is to cover it with whatever material (gravel, sand, soil) you decide to use as soon as possible. Instead of dumping the entire load right away, you should carefully drop your geotextile filter fabric material on the fabric's center and nicely spread it to the edges so as not to shift or tear the fabric.

Step 6: Final Placement

You are free to perform the last step according to your preference - adding pavers, gravel, etc. While working against the geo textile material (e.g., in a retaining wall), be cautious if you use a large stone as it might puncture the fabric with its sharp edge.

Common Mistakes to Avoid

- Insufficient Overlap: Not putting enough layers on top of each other is the cause that leads most often to failure. Through the gaps, the soil can need to be migrated and the separation function is undermined.

- Using the Wrong Side: Despite the majority of non woven geotextiles being the same on both sides, a few feature a smooth side and a fuzzy side. Usually, the fuzzy part faces the soil for better adhesion. You may want to verify this at the manufacturer's guide.

- Prolonged UV Exposure: A running joke about plastic pollution is that it takes a millennium to decay; the truth is that polythene is only a couple of decades old and it is the same with geotextiles. Keeping the fabric in direct sunlight for an extended period of time will cause it to weaken.

- Using it as a Primary Erosion Control on Steep Slopes:If that is the case, then you should be looking at specialized erosion control mats or heavier woven fabrics as the answer to that question. The 8 oz geotextile fabric is really more about stabilization underneath the cover layer.

Conclusion

The 8 oz geotextile fabric is a versatile engineering material that has proven to be a great tool in solving in a very effective manner fundamental problems such as separation, drainage, and stabilization. Due to the fact that it is not very heavy, it is possible to use it for a multitude of projects, starting from a residential gravel driveway all the way to sophisticated drainage and civil engineering systems. Hence, it is possible to keep the lifecycle longer and aggregate the performance level of the construction by undertaking the study of the product's operational features, picking the right product for each use, and following the correct installation procedures.

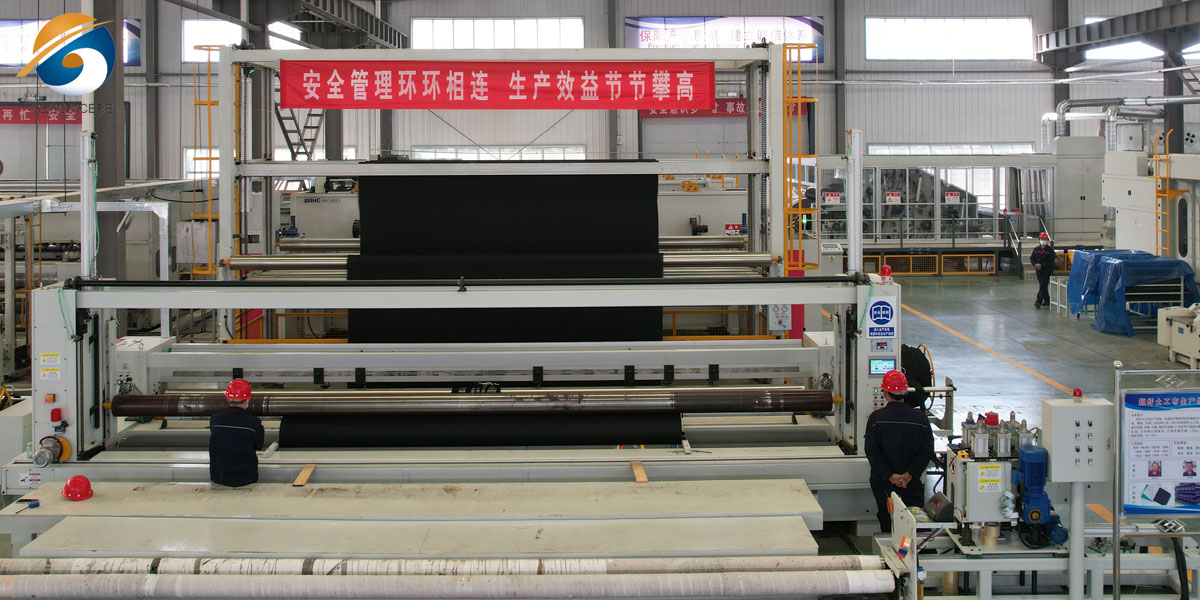

Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) is a brand that one can trust for factory-direct quality 8 oz geotextile fabric that are under strict quality control. Highly skilled and globally experienced, working thus can offer you geotextile substructure solutions that assure the long-term stability and functionality of your project.

It is a simple layer that delivers a complex yet essential solution—protecting what you build on the surface and keeping it stable, durable, and functional for years to come.