Geomembrane HDPE Liner Cost Per m2

Manufacturing Process

Raw Material Drying

HDPE resin is dried to meet moisture control standards, preventing bubble defects.Extrusion Melting

High-capacity extruders melt resin at 200–260°C with precise temperature zones.Blown Film or Flat Die Casting

Sheet is formed using a multi-layer extrusion die for uniform thickness.Cooling & Calendering

Rollers stabilize thickness and surface texture.Corona Treatment

Enhances surface bonding performance for welded joints.Automatic Winding & Inspection

Full-roll inspection includes thickness tolerance, gel count, and visual defects.

Product Definition

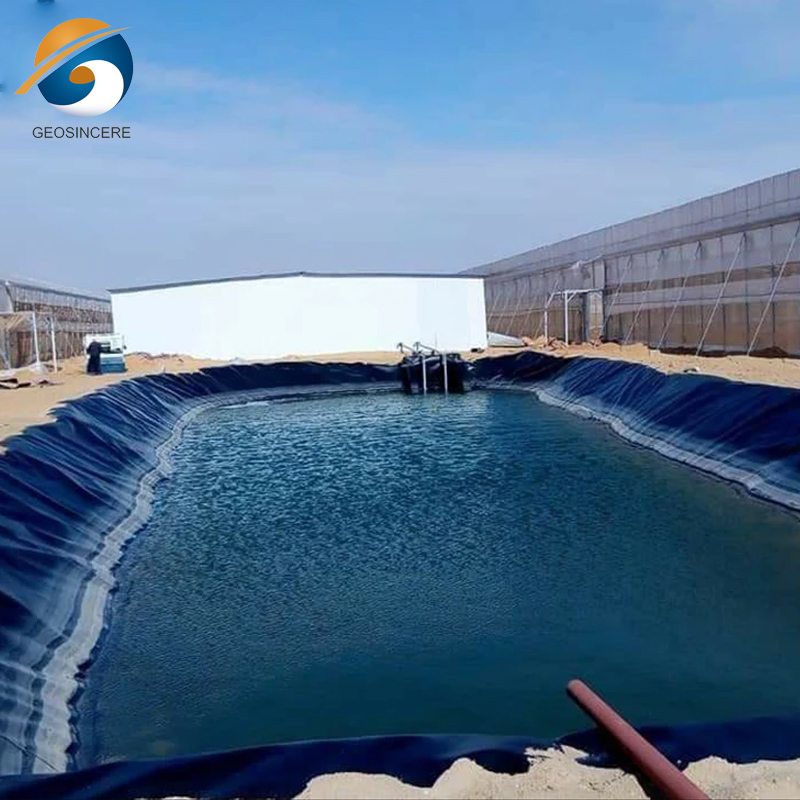

HDPE geomembrane liner is a thermoplastic impermeable sheet made from high-density polyethylene. It is engineered for landfill, mining, aquaculture, and water containment projects where chemical resistance, durability, and leakage control are required.

Technical Parameters & Specifications

Material: High-Density Polyethylene (≥97% HDPE resin)

Thickness Options: 0.5 mm / 0.75 mm / 1.0 mm / 1.5 mm / 2.0 mm

Standard Width: 5.8 m–8.0 m (suitable for container loading)

Tensile Strength: 16–30 MPa

Elongation at Break: ≥700%

Puncture Resistance: 400–800 N

Carbon Black Content: 2–3% (UV protection)

Expected Service Life: 50–75 years (depending on UV exposure)

Structure & Material Composition

HDPE Base Resin — Provides tensile strength and long-term durability.

Carbon Black — Enhances UV resistance for outdoor landfill usage.

Antioxidants & Stabilizers — Reduce thermo-oxidative degradation.

Optional Textured Surface — Improves interface friction coefficient.

Manufacturing Process

Raw Material Drying

HDPE resin is dried to meet moisture control standards, preventing bubble defects.Extrusion Melting

High-capacity extruders melt resin at 200–260°C with precise temperature zones.Blown Film or Flat Die Casting

Sheet is formed using a multi-layer extrusion die for uniform thickness.Cooling & Calendering

Rollers stabilize thickness and surface texture.Corona Treatment

Enhances surface bonding performance for welded joints.Automatic Winding & Inspection

Full-roll inspection includes thickness tolerance, gel count, and visual defects.

Industry Comparison

| Material | Impermeability | Chemical Resistance | Cost per m2 | Service Life |

|---|---|---|---|---|

| HDPE Geomembrane | Excellent | Excellent | Low–Medium | 50–75 years |

| LLDPE Geomembrane | Very Good | Good | Medium | 30–50 years |

| Clay Liner (GCL) | Moderate | Poor | Medium–High | 20–30 years |

| Concrete Lining | Moderate | Moderate | High | 40–60 years |

Application Scenarios

EPC contractors handling landfill cell construction.

Mining operators requiring heap leach pads.

Water treatment and reservoir containment projects.

Chemical storage ponds requiring corrosion resistance.

Distributors supplying municipal solid waste projects.

Core Pain Points & Engineering Solutions

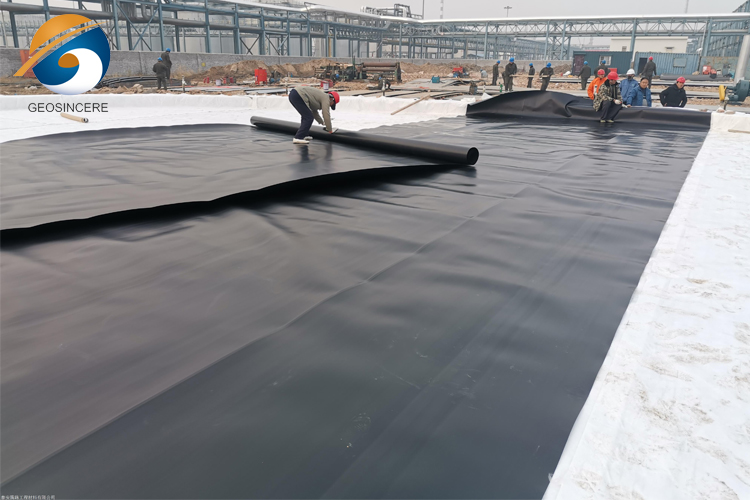

Leakage Risk: Use 1.5–2.0 mm HDPE liner with double hot-wedge welding to ensure seam integrity.

UV Degradation: Select 3% carbon-black content for long-term outdoor exposure.

Puncture from Sub-base: Install geotextile cushioning layer (≥300 g/m2) beneath the liner.

Difficult On-site Welding: Use IGBT-controlled welders and conduct destructive seam tests every 150–200 m.

Risk Warnings & Avoidance Recommendations

Do not install when winds exceed 25 km/h or temperatures below 5°C.

Avoid sharp objects and untreated subgrade surfaces.

Ensure QC testing for every welding section, including vacuum box and air channel tests.

Check supplier certificates: ISO 9001, GRI-GM13 compliance, and UV resistance reports.

Procurement Selection Guide

Define project requirements and target impermeability grade.

Choose appropriate thickness based on landfill type and loading.

Confirm resin origin (preferably prime-grade HDPE, not recycled).

Request third-party test reports confirming GRI-GM13 compliance.

Evaluate total installation cost, not only the geomembrane HDPE liner cost per m2.

Select suppliers providing welding equipment, onsite guidance, and QC documentation.

Engineering Case: Municipal Landfill Cell

A 1.2-million-ton municipal landfill expansion required a multilayer barrier system. Engineers selected a 2.0 mm HDPE geomembrane liner combined with 300 g/m2 geotextile and compacted clay. Over 130,000 m2 of liner were installed using dual-track welding. Seam test results met all GRI-GM13 requirements, and leakage monitoring showed zero failures during the first operational year.

FAQ

What affects geomembrane HDPE liner cost per m2? Thickness, resin grade, surface texture, and order quantity.

Is textured liner more expensive? Yes, due to additional production steps.

What is the standard lifespan? 50–75 years depending on UV exposure.

Can HDPE liner be used for high-temperature waste? Only up to ~60°C; above this, special materials are required.

How wide are common rolls? 5.8–8.0 m for container optimization.

What welding method is recommended? Dual hot-wedge welding.

Do I need geotextile underlayment? Yes, for puncture protection.

Is GM13 compliance mandatory? Strongly recommended for landfill applications.

How to verify material quality? Check melt index, density, carbon black, and tensile properties.

What is the ideal thickness for landfills? 1.5–2.0 mm depending on design load.

Request Quotation / Technical Documents / Samples

For engineering design data, project quotations, or HDPE liner samples, please contact our technical team for a detailed consultation tailored to your landfill application.

E-E-A-T Author Credentials

The content is prepared by an industry specialist with over 12 years of engineering experience in geosynthetics manufacturing, QC testing, and landfill barrier system design. Knowledge includes GRI-GM13 standards, installation QA/QC, and EPC project execution.