Geomembrane Liner

A geomembrane liner is a crucial component in various environmental and engineering applications, designed to serve as a barrier to prevent the migration of fluids or gases. Typically made from high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or other synthetic materials, these liners exhibit exceptional durability and resistance to chemical degradation, UV radiation, and punctures. Geomembranes are widely used in landfill construction, where they line the bottom and sides of landfill cells to contain leachate and prevent soil and groundwater contamination. In the mining industry, they are employed to manage tailings and prevent harmful substances from entering the environment. Additionally, geomembrane liners are integral to water conservation projects, such as reservoirs, canals, and ponds, where they minimize evaporation and seepage, ensuring efficient water storage. Their versatility extends to agricultural applications, where they help manage irrigation and drainage systems. Overall, geomembrane liners are essential for protecting the environment and managing resources sustainably, offering a reliable solution for fluid containment and environmental protection.

Geomembrane Liner: Unmatched Protection for Environmental and Industrial Applications

The geomembrane liner is an essential material used in various environmental and industrial applications to provide high-performance protection against contamination and seepage. Whether in landfills, wastewater treatment plants, mining operations, or containment systems, the geomembrane liner offers superior impermeability and durability, ensuring environmental safety and compliance with regulatory standards.

This high-quality liner is designed to prevent leakage of harmful liquids and gases, protecting both the surrounding environment and underlying structures. The geomembrane liner is widely trusted in industries where containment of liquids, hazardous substances, and waste is critical for environmental protection and operational efficiency.

What is a Geomembrane Liner?

A geomembrane liner is a synthetic barrier material made from high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), PVC, or other polymer materials, used for a variety of containment applications. These liners are designed to create a secure and impermeable layer that prevents the migration of liquids, solids, and gases from one environment to another. With excellent resistance to UV radiation, chemicals, and temperature fluctuations, geomembrane liners provide reliable long-term performance in harsh conditions.

Used in a wide range of applications, geomembrane liners are essential for projects requiring high resistance to punctures, tears, and chemical degradation. They offer effective solutions for applications ranging from waste management to water containment and mining operations.

Key Features of Geomembrane Liner

Choosing a geomembrane liner offers several advantages that ensure maximum protection and longevity for containment projects:

High Impermeability: The primary function of a geomembrane liner is to prevent the movement of liquids, gases, and other substances. Its impermeable nature ensures that contaminants do not migrate to the surrounding environment, making it a key component for environmental protection.

Durability and Longevity: The geomembrane liner is designed for long-term use in harsh environments. Resistant to punctures, tears, and chemical degradation, it provides a reliable solution for extended periods, reducing the need for frequent replacements.

Chemical Resistance: Made from advanced polymers, the geomembrane liner is resistant to a wide range of chemicals, including acids, solvents, and oils. This makes it ideal for use in industries such as mining, waste management, and oil and gas.

UV and Temperature Resistance: The geomembrane liner is specially engineered to withstand the damaging effects of UV radiation and temperature fluctuations, ensuring it maintains its integrity even under exposure to harsh sunlight or extreme temperatures.

Flexibility and Ease of Installation: Available in rolls or sheets, the geomembrane liner can be easily customized to fit specific applications. It is flexible and easy to install, minimizing the time and labor required for the project.

Environmental Compatibility: The geomembrane liner is eco-friendly and non-toxic, making it a safe choice for projects that require environmental protection and compliance with sustainability standards.

Benefits of Using Geomembrane Liner

The geomembrane liner offers several benefits that make it the preferred choice for industries requiring reliable containment solutions:

Protection Against Contamination: By acting as an impermeable barrier, the geomembrane liner prevents the seepage of harmful substances into the surrounding soil or water sources. This is critical for industries that deal with hazardous materials or waste.

Cost-Effective Solution: The durability and low maintenance requirements of the geomembrane liner make it a cost-effective option for long-term containment projects. It reduces the need for frequent repairs or replacements, saving on operational costs.

Improved Safety: The geomembrane liner significantly reduces the risk of leaks or contamination, enhancing safety for workers and the surrounding environment. Its effective containment properties help meet safety and regulatory standards in various industries.

Increased Operational Efficiency: With its easy installation and low maintenance needs, the geomembrane liner improves operational efficiency. It helps ensure that containment projects are completed on time and within budget.

Versatility: The geomembrane liner is adaptable to a wide range of applications, including landfill liners, ponds, reservoirs, irrigation systems, mining pits, and waste storage. It provides a versatile solution for various environmental and industrial projects.

Common Applications of Geomembrane Liner

The geomembrane liner is used in several critical industries where containment, protection, and environmental safety are of utmost importance. Some common applications include:

Landfill Liners: Geomembrane liners are essential in landfills for containing leachate and preventing the contamination of surrounding soil and groundwater. These liners ensure that hazardous waste remains confined within the landfill, safeguarding the environment.

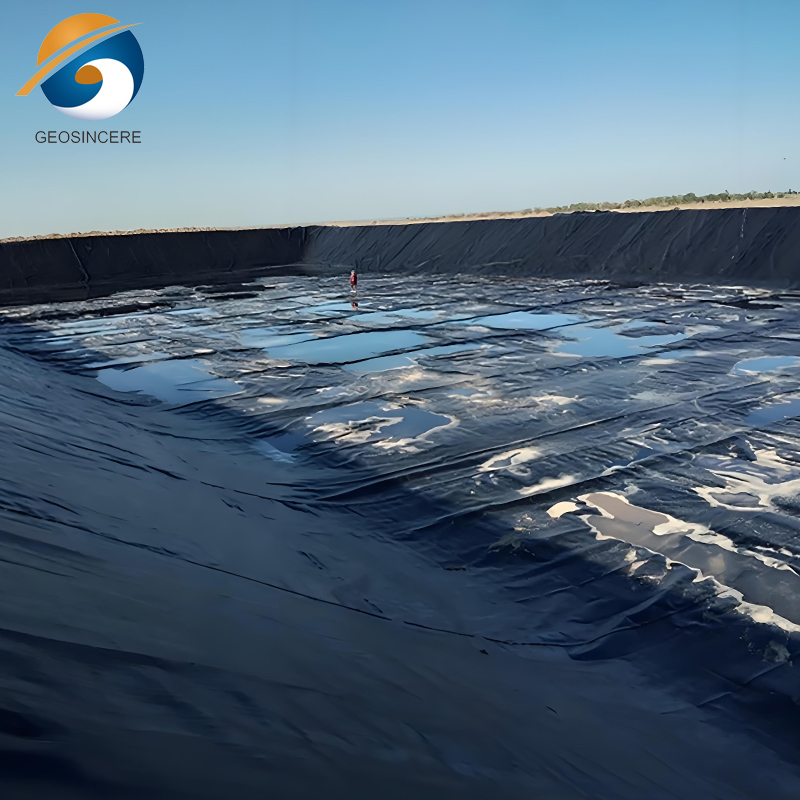

Water Reservoirs and Ponds: In water reservoirs, ponds, and lakes, geomembrane liners help prevent water loss due to seepage and provide containment for water storage systems. They are used in both potable and non-potable water containment projects.

Wastewater Treatment Plants: Geomembrane liners are widely used in wastewater treatment plants to line lagoons and ponds, ensuring the containment of wastewater and preventing leaks into the surrounding environment.

Mining Operations: The geomembrane liner is a vital component in mining operations, used for tailings ponds, heap leaching, and waste containment. It helps prevent the contamination of groundwater from harmful chemicals and mining by-products.

Agriculture and Irrigation Systems: In agricultural applications, geomembrane liners are used for irrigation channels and reservoirs to minimize water loss and prevent contamination of irrigation water.

Oil and Gas: The geomembrane liner is utilized in the oil and gas industry to line storage tanks, containment pits, and secondary containment systems, providing protection against leaks and spills of hazardous materials.

The wide range of applications highlights the versatility and importance of geomembrane liners in ensuring environmental protection and operational efficiency across multiple sectors.

How to Install and Maintain Geomembrane Liner

Installing a geomembrane liner requires careful preparation and proper handling to ensure maximum performance and longevity. Here’s how to properly install and maintain a geomembrane liner:

Preparation: Ensure the installation area is clean and free of debris. The surface should be smooth and level to prevent punctures or tears in the liner during installation.

Customization: The geomembrane liner should be customized to the dimensions of the area it will cover. It can be cut and welded to fit specific requirements.

Installation: Install the geomembrane liner by unrolling it over the prepared surface, ensuring that all seams are properly sealed. The liner can be joined using heat welding, adhesive bonding, or mechanical fasteners.

Testing: After installation, test the liner for leaks and ensure that it is fully impermeable. Conduct regular inspections to ensure its integrity over time.

Maintenance: While geomembrane liners require minimal maintenance, periodic inspections should be conducted to check for signs of damage, wear, or degradation. Any damage should be repaired promptly to maintain the liner’s effectiveness.

Why Choose Geomembrane Liner?

The geomembrane liner is the ideal solution for a wide range of containment projects, offering unmatched durability, flexibility, and environmental protection. Whether you are working on a landfill, mining operation, or water containment system, the geomembrane liner ensures that your project will meet safety standards, reduce environmental risks, and provide long-lasting protection.

By choosing the geomembrane liner, you are investing in a high-performance product that ensures operational efficiency, cost savings, and superior environmental protection. Its strength, resistance to wear, and ability to withstand harsh conditions make it the best choice for industries where containment is critical.

Conclusion

In conclusion, the geomembrane liner is a vital component for any project requiring containment, protection, and environmental safety. Its superior impermeability, chemical resistance, and long-lasting durability make it the perfect choice for a variety of industrial and environmental applications. With its versatility, cost-effectiveness, and ease of installation, the geomembrane liner provides a reliable solution for your containment needs.

Choose the geomembrane liner for your next project and experience the ultimate in environmental protection and operational efficiency.