Waterproof Preformed Pond Liner Membrane for Artificial Lake

HDPE is a durable and robust material that offers excellent resistance to UV radiation, chemicals, and punctures. It is known for its high strength and dimensional stability, which makes it suitable for large-scale applications like artificial lakes.HDPE pond liners provide a waterproof barrier that prevents water from seeping into the ground and helps retain the water within the artificial lake. The impermeable nature of HDPE ensures that the lake remains filled and minimizes the risk of leakage.

HDPE pond liners are available in various sizes and can be customized to fit the specific dimensions and shape of your artificial lake to match your requirements accurately.HDPE liners have a long lifespan and can withstand environmental conditions, including temperature variations and ultraviolet (UV) exposure. When properly installed and maintained, they can provide reliable waterproofing for many years.

The construction of artificial lakes for landscaping, recreation, aquaculture, or stormwater retention requires precise engineering and durable waterproofing solutions. One of the most reliable materials used in these applications is the waterproof preformed pond liner membrane. This article offers a detailed overview of the structural, regulatory, and operational aspects of preformed pond liner membranes in artificial lake projects.

Table of Contents

What is a Preformed Pond Liner Membrane?

Engineering Properties and Material Specifications

Advantages in Artificial Lake Construction

Installation Guidelines and Site Considerations

Compliance with Environmental and Engineering Standards

Common Mistakes and How to Avoid Them

Frequently Asked Questions (FAQs)

Conclusion and Professional Recommendations

1. What is a Preformed Pond Liner Membrane?

A preformed pond liner membrane is a factory-molded geomembrane, designed to maintain its shape and integrity when installed. It differs from flexible liners by offering a more rigid, predefined geometry, making it ideal for controlled environments like decorative artificial lakes, koi ponds, and residential or commercial water features.

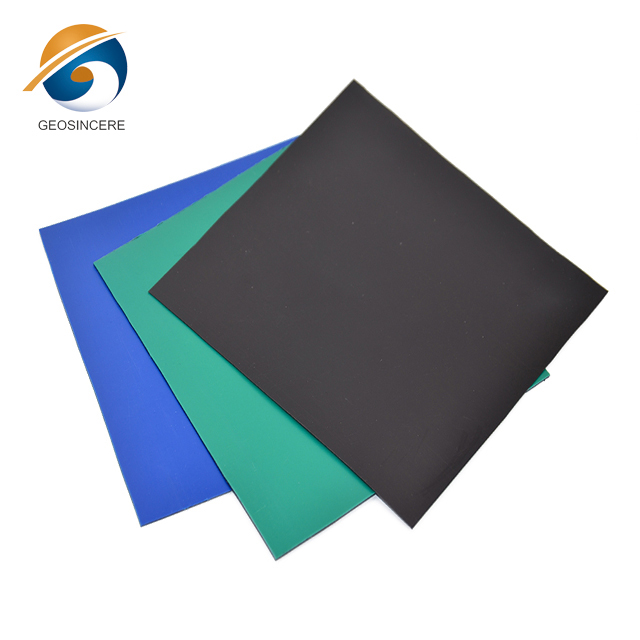

These liners are typically constructed from high-density polyethylene (HDPE), low-density polyethylene (LDPE), or reinforced polypropylene (RPP). Their pre-molded structure offers added strength and simplifies installation in circular or symmetrical basins.

2. Engineering Properties and Material Specifications

Key Material Characteristics:

Tensile Strength: ≥16 MPa for HDPE (ASTM D638)

Puncture Resistance: ≥600 N (ASTM D4833)

Water Vapor Permeability: <1.0 × 10⁻¹³ g·cm/(cm²·s·Pa)

UV Resistance: >90% retention after 1600 hours (ASTM G154)

Thickness Ranges:

Typically 0.75 mm to 2.0 mm depending on usage and regulatory requirements.

Roll Dimensions:

While not in rolls, standard prefabricated membranes come in modular panels or molded forms.

3. Advantages in Artificial Lake Construction

Waterproof Integrity: Reduced risk of seam failures compared to flexible liners.

Longevity: Service life exceeding 20 years in UV-exposed outdoor applications.

Easy Maintenance: Preformed liners reduce sediment accumulation in folds or creases.

Fast Installation: Eliminates the need for on-site welding or seaming in small to medium applications.

Aesthetic Appeal: Offers a smooth, clean finish ideal for visible water features.

4. Installation Guidelines and Site Considerations

Subgrade Preparation:

Compact and smooth the lake bed to avoid puncturing the liner.

Remove sharp rocks, roots, and other debris.

Anchoring:

Use anchor trenches or perimeter weights for stability.

Avoid stretching or forcing the liner into an irregular shape.

Backfilling and Protection:

Protect the liner from direct mechanical stress by applying a non-woven geotextile underlay.

Add a protective soil or sand layer before filling the lake with water.

Hydrostatic Pressure:

Ensure outlet drains or overflow systems are in place to manage excess water, as trapped hydrostatic pressure can deform rigid liners.

5. Compliance with Environmental and Engineering Standards

Projects involving artificial lakes must conform to local and international guidelines. Common regulatory references include:

EPA (U.S. Environmental Protection Agency) for aquaculture and water retention safety.

ASTM D5885 for leakage rates in geomembranes.

ISO 9001:2015 quality management systems in manufacturing.

ISO 14001 for environmental impact compliance.

For public or commercial projects, professional engineering consultation and municipal approval may be required.

6. Common Mistakes and How to Avoid Them

Incorrect Liner Selection: Use UV-stabilized liners in exposed areas. Avoid garden liners in large-scale lakes.

Poor Subgrade: Failing to level and compact the base can lead to long-term damage.

Lack of Overflow Management: Always incorporate an overflow system to prevent liner displacement.

7. Frequently Asked Questions (FAQs)

Q1: Can preformed liners be used for large lakes?

A: They are ideal for small to medium installations. Larger artificial lakes typically use custom-fabricated HDPE panels with field seaming.

Q2: Are preformed membranes safe for fish and plants?

A: Yes, food-grade HDPE or LDPE liners are non-toxic and suitable for aquaculture and ornamental ponds.

Q3: What is the typical lifespan of a preformed pond liner?

A: 15–25 years, depending on UV exposure, chemical contact, and mechanical stress.

Q4: Do I need a geotextile under a preformed liner?

A: Yes, a cushioning layer is essential to protect against punctures and improve liner stability.

8. Conclusion and Professional Recommendations

Preformed pond liner membranes are an efficient and durable choice for artificial lakes, offering simplified installation, consistent waterproofing performance, and compatibility with modern landscaping and aquaculture systems. By adhering to engineering best practices and environmental standards, these liners can deliver long-term performance with minimal maintenance.

Call to Action

If you're planning an artificial lake project and require expert guidance on selecting and installing preformed pond liners, contact our engineering team for a site-specific consultation. We provide technical drawings, compliance documentation, and installation support to ensure your project is both structurally sound and environmentally compliant.

Excellent Chemical Resistance.

Outstanding Stress Crack Capacity.

Lowest Permeability.

Excellent UV Resistance.

Stable Low Temperature Embrittlement Resistance.

Proven Performance.

Fast Deployment.

Easy Transportation.

ISO9001 Certificated Geomembrane Factory.

Meet or Exceed All Aspects of GRI GM13.

Complete Width and Thickness Specifications.

Competitive Factory Price.

ODM/OEM are Available.

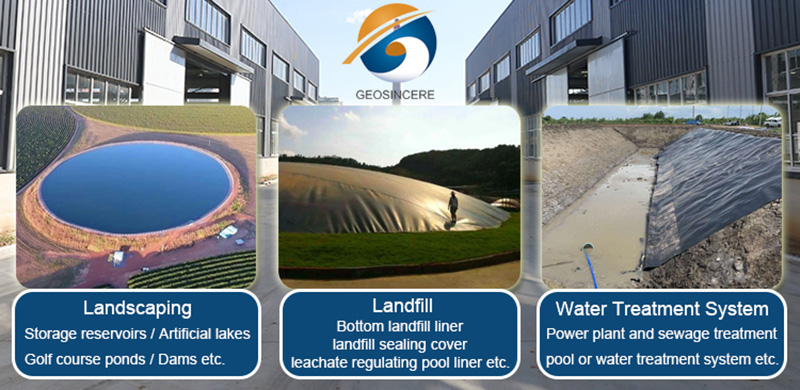

Applications of Waterproof Preformed Pond Liner Membrane

Waterproof preformed pond liner membranes have a wide range of applications beyond artificial lakes. Here are some common uses:

Garden Ponds and Water Features: Preformed pond liners are frequently used to create garden ponds, water gardens, and decorative water features. They provide a watertight barrier that prevents water from seeping into the surrounding soil, ensuring the pond retains its water.

Fish Ponds and Aquaculture: Waterproof pond liners are essential for fish ponds and aquaculture systems. They create a controlled environment for raising fish, ensuring that water is contained and preventing contamination from the surrounding soil.

Retention and Detention Ponds: Preformed pond liners are often employed in the construction of retention and detention ponds, which are designed to store excess rainwater and control stormwater runoff. These ponds help prevent flooding and manage water drainage in urban and commercial areas.

Water Reservoirs and Tanks: Preformed pond liners are utilized in the construction of water reservoirs, tanks, and cisterns. They provide a reliable barrier to contain water for various purposes, including irrigation, firefighting, and industrial use.

Golf Course Water Hazards: Many golf courses incorporate water hazards as part of their design. Preformed pond liners are used to create these water features, ensuring they hold water and maintain their aesthetic appeal.

Wetlands and Natural Filtration Systems: For the construction of wetlands and natural filtration systems, preformed pond liners are used to create the necessary water containment structures. These systems help purify water by utilizing natural processes and beneficial plant and microbial communities.

Decorative Ponds and Landscape Design: Preformed pond liners are commonly employed in landscape design to create decorative ponds, reflecting pools, and waterfalls. They allow for the creation of visually appealing water features that enhance the overall aesthetics of gardens and outdoor spaces.