Landfill Cover Black 1.5mm Plastic Geomembrane Pond Liner

The Landfill Cover Black 1.5mm Plastic Geomembrane Pond Liner has become a cornerstone material in modern environmental engineering and water management projects. This geomembrane plays a critical role in preventing seepage, controlling waste leachate, and protecting soil and groundwater from contamination. As sustainability and environmental compliance gain importance worldwide, the demand for high-performance geomembrane liners continues to rise across landfills, mining facilities, agricultural ponds, and wastewater treatment plants.

According to global market research, the geomembrane industry surpassed USD 2.6 billion in 2024, with an expected CAGR of 6.5% through 2030. The black 1.5mm HDPE geomembrane liner segment has seen particularly strong growth, driven by its balance of tensile strength, impermeability, and cost-effectiveness. Asia-Pacific and North America remain the primary production and consumption regions due to large-scale environmental and infrastructure projects.

Global Overview of Landfill Cover Black 1.5mm Plastic Geomembrane Pond Liner

The Landfill Cover Black 1.5mm Plastic Geomembrane Pond Liner has become a cornerstone material in modern environmental engineering and water management projects. This geomembrane plays a critical role in preventing seepage, controlling waste leachate, and protecting soil and groundwater from contamination. As sustainability and environmental compliance gain importance worldwide, the demand for high-performance geomembrane liners continues to rise across landfills, mining facilities, agricultural ponds, and wastewater treatment plants.

According to global market research, the geomembrane industry surpassed USD 2.6 billion in 2024, with an expected CAGR of 6.5% through 2030. The black 1.5mm HDPE geomembrane liner segment has seen particularly strong growth, driven by its balance of tensile strength, impermeability, and cost-effectiveness. Asia-Pacific and North America remain the primary production and consumption regions due to large-scale environmental and infrastructure projects.

Market Trends and Industry Dynamics

The increasing adoption of 1.5mm plastic geomembrane pond liners is primarily influenced by tightening environmental regulations and the global shift toward waste management efficiency. The construction of modern sanitary landfills, aquaculture farms, and water reservoirs has led to a surge in liner demand.

In 2025, global procurement data indicates that HDPE geomembrane usage for landfill capping and containment increased by over 12% year-on-year. Government-funded waste management programs in developing regions, particularly in Africa and Southeast Asia, are boosting demand for standardized liners that meet ASTM and GRI-GM13 specifications.

Technical Specifications and Performance Characteristics

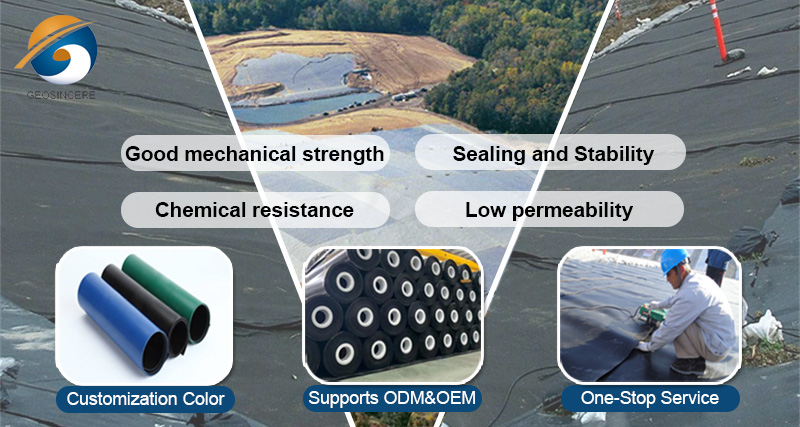

The Landfill Cover Black 1.5mm Plastic Geomembrane Pond Liner offers exceptional impermeability and mechanical stability. Key technical parameters typically include:

- Thickness: 1.5mm (nominal tolerance ±0.05mm) - Density: ≥0.94 g/cm³ - Tensile Strength at Yield: ≥27 MPa - Elongation at Break: ≥700% - Tear Resistance: ≥150 N - Puncture Resistance: ≥480 N - Carbon Black Content: 2–3% for UV protection

This combination ensures optimal resistance to puncture, stress cracking, and ultraviolet degradation. The black coloration further enhances long-term durability under sunlight, making it ideal for exposed applications such as landfill caps and agricultural ponds.

Product Structure and Material Composition

The geomembrane is manufactured using high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE) resins blended with carbon black, antioxidants, and anti-aging agents. The uniform 1.5mm structure provides an excellent balance between flexibility and stiffness, allowing it to conform to varying subgrade conditions without compromising integrity.

For landfill applications, the liner is often combined with non-woven geotextile layers to create a composite system that enhances drainage and puncture resistance. The smooth or textured surface options allow better frictional performance when used in slopes or vertical containment structures.

Manufacturing Process and Quality Control

The 1.5mm HDPE geomembrane liner is typically produced through advanced extrusion or co-extrusion technology. During production, the polymer resin is melted and extruded through flat dies, forming a continuous sheet that is then cooled, trimmed, and rolled.

Quality assurance protocols include continuous thickness monitoring, tensile testing, and oxidation induction time (OIT) evaluations. Every batch undergoes hydrostatic pressure and thermal aging tests to ensure compliance with ASTM D5199 and ISO 9001 standards. This meticulous process guarantees consistent product performance across various environmental applications.

Applications in Landfill, Pond, and Environmental Projects

The Landfill Cover Black 1.5mm Plastic Geomembrane Pond Liner is extensively used in:

- **Landfill Liners and Covers:** To prevent leachate seepage and gas emissions. - **Aquaculture Ponds:** For lining fish and shrimp ponds, reducing seepage and improving water retention. - **Water Reservoirs and Canals:** Providing a durable and impermeable base for long-term containment. - **Mining Tailings Dams:** Acting as a chemical barrier to prevent heavy metal contamination.

In landfill applications, the liner is typically installed with heat-welded seams, forming a continuous barrier system that minimizes leakage risks and extends service life.

Pricing Factors and Market Differentiation

The Landfill Cover Black 1.5mm Plastic Geomembrane Pond Liner price varies according to material grade, thickness, surface texture, and shipping region. Global average prices range from USD 1.8–3.5 per square meter.

Additional costs may arise from on-site welding services, quality testing, and installation support. Buyers in regions with limited domestic production—such as South America and the Middle East—often pay higher prices due to freight charges and import duties. Conversely, large-volume orders from Asia-Pacific benefit from economies of scale.

International Buyer Preferences and Pain Points

Global buyers prioritize three key factors when sourcing geomembrane liners: consistency, certification, and customization. Procurement teams seek suppliers who provide technical documentation, test reports, and long-term warranty assurance.

Common buyer pain points include inconsistent quality between batches, delays in shipping, and insufficient after-sales technical support. To address these concerns, experienced manufacturers are offering integrated solutions that include on-site guidance, pre-welding consultation, and digital traceability for each roll.

Future Trends and Sustainability Outlook

The global geomembrane market is transitioning toward more sustainable production and recycling methods. Manufacturers are developing geomembranes using partially recycled HDPE materials and adopting energy-efficient extrusion systems.

Digital procurement systems and AI-driven quality monitoring are also reshaping the market, allowing buyers to verify liner performance through digital certificates and real-time inspection data. These innovations are expected to stabilize geomembrane liner pricing and strengthen transparency throughout the supply chain.

Frequently Asked Questions (FAQ)

1. What is the expected service life of a 1.5mm geomembrane liner?

Under normal environmental conditions, a 1.5mm HDPE geomembrane can last 15–20 years when properly installed and maintained.

2. What testing standards apply to landfill geomembrane liners?

Common standards include ASTM D5199 for thickness, ASTM D6693 for tensile strength, and GRI-GM13 for overall performance certification.

3. Can the geomembrane liner be customized for specific projects?

Yes. Liners can be manufactured in various widths, roll lengths, and surface textures based on project design and site requirements.

4. How do buyers ensure the quality of imported geomembranes?

Buyers should request factory inspection reports, third-party testing certificates, and sample verification before shipment.

Request a Quotation or Technical Data Sheet

We supply high-performance Landfill Cover Black 1.5mm Plastic Geomembrane Pond Liners designed for durability and environmental compliance. Our team provides customized material recommendations, technical consultations, and sample evaluations for international buyers.

Contact us today to obtain a detailed quotation, updated geomembrane price list, and professional engineering support for your landfill, pond, or industrial containment project.