Landfill Pond Liner HDPE Impermeable Membrane

Manufacturing Process and Engineering Controls

Production Flow

Resin and additive incoming inspection

Automated gravimetric batching

High-temperature blown film or flat die extrusion

Online thickness scanning

Surface texturing (if required)

Controlled cooling and stress relief

Roll winding with tension control

Factory mechanical and index testing

Landfill Pond Liner HDPE Impermeable Membrane is a high-density polyethylene barrier sheet engineered for landfill cells and containment ponds to prevent leachate migration and groundwater contamination under long-term load and chemical exposure.

Technical Parameters and Specifications

For engineering procurement, Landfill Pond Liner HDPE Impermeable Membrane must be specified with measurable mechanical, hydraulic, and durability properties. Values below reflect commonly accepted engineering ranges used in containment and landfill liner systems.

| Parameter | Typical Range | Test Reference |

|---|---|---|

| Thickness | 1.0 – 3.0 mm | ASTM D5199 |

| Density | ≥ 0.94 g/cm³ | ASTM D1505 |

| Tensile Strength (Yield) | ≥ 15 kN/m | ASTM D6693 |

| Elongation at Break | ≥ 700% | ASTM D6693 |

| Tear Resistance | ≥ 90 N | ASTM D1004 |

| Puncture Resistance | ≥ 320 N | ASTM D4833 |

| Carbon Black Content | 2.0 – 3.0% | ASTM D4218 |

| Permeability Coefficient | ≤ 1×10⁻¹³ cm/s | GRI method |

Engineering submittals for Landfill Pond Liner HDPE Impermeable Membrane should include full roll batch test reports and welding compatibility data.

Structure and Material Composition

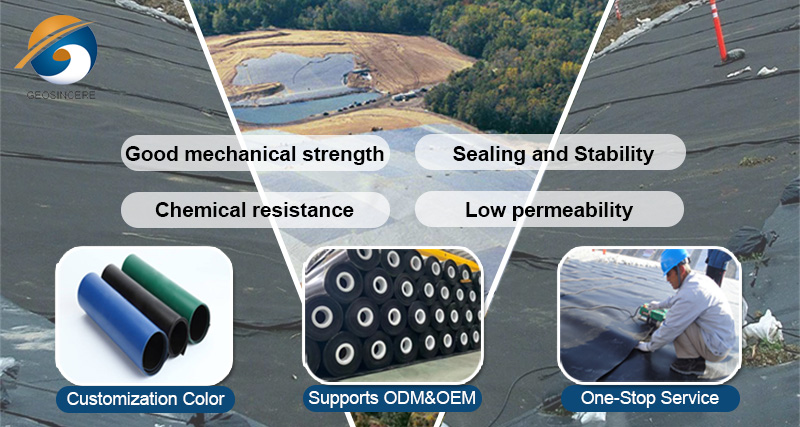

The performance of Landfill Pond Liner HDPE Impermeable Membrane depends on polymer quality and additive control.

Base Polymer: Virgin high-density polyethylene resin

Carbon Black: UV stabilization and oxidation resistance

Antioxidant Package: Thermal aging control

Processing Stabilizers: Melt flow and extrusion stability

Surface Type: Smooth or textured for slope friction

Optional Layering: Co-extruded surface for improved welding

Virgin resin is typically specified for landfill and hazardous containment use of Landfill Pond Liner HDPE Impermeable Membrane to ensure long-term durability.

Manufacturing Process and Engineering Controls

Production Flow

Resin and additive incoming inspection

Automated gravimetric batching

High-temperature blown film or flat die extrusion

Online thickness scanning

Surface texturing (if required)

Controlled cooling and stress relief

Roll winding with tension control

Factory mechanical and index testing

Key Equipment

Wide-width geomembrane extrusion lines

Automatic thickness gauge systems

Carbon black dispersion testers

Tensile and puncture test machines

Oxidative induction time analyzers

Process stability directly affects weld performance of Landfill Pond Liner HDPE Impermeable Membrane in field installation.

Industry Comparison with Alternative Liners

| Liner Type | Chemical Resistance | Service Life | Weldability | Typical Use |

|---|---|---|---|---|

| HDPE Membrane | Excellent | Long | Hot wedge / extrusion | Landfill, leachate ponds |

| LLDPE Membrane | Very good | Medium–Long | Good | Flexible basins |

| PVC Liner | Moderate | Medium | Solvent weld | Decorative ponds |

| Clay Liner | Variable | Dependent | Not welded | Low-risk sites |

For regulated sites, Landfill Pond Liner HDPE Impermeable Membrane is typically preferred due to chemical stability and seam integrity.

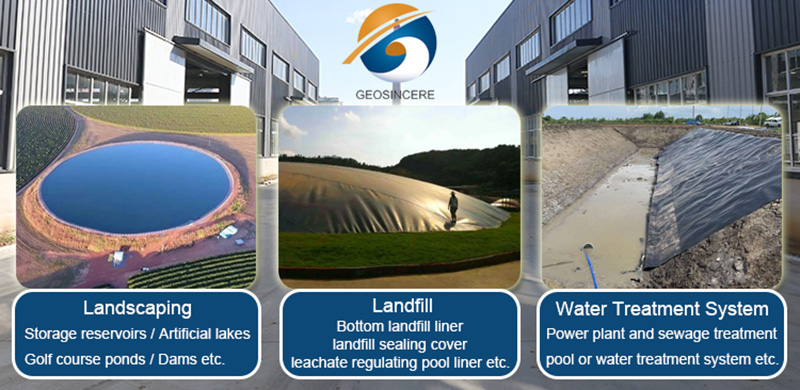

Application Scenarios

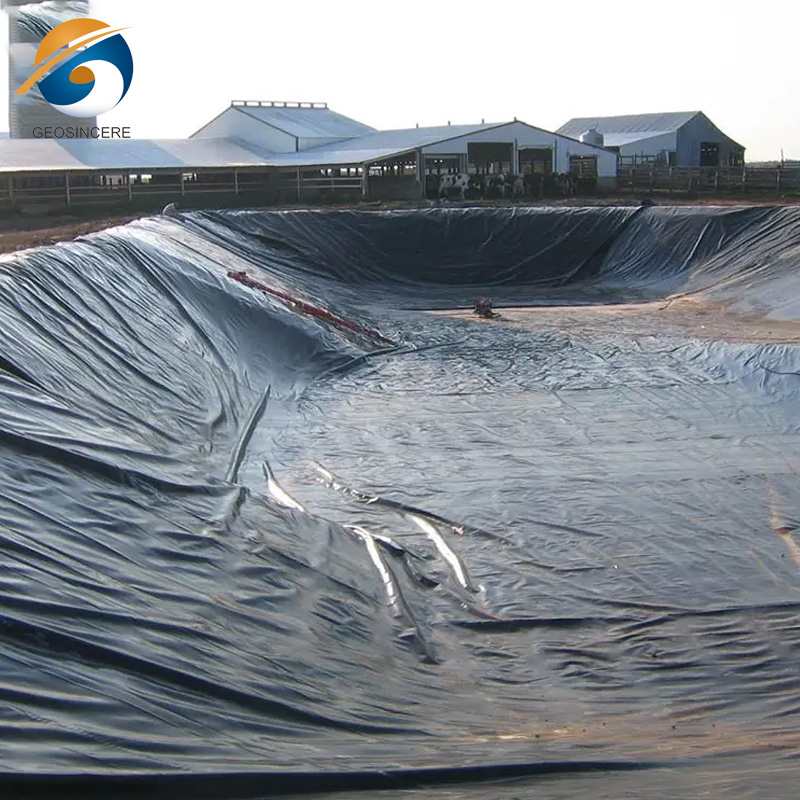

Municipal landfill bottom liners

Leachate collection ponds

Industrial waste containment

Tailings and slurry ponds

Hazardous liquid storage basins

Secondary containment systems

Distributors and EPC contractors often standardize on Landfill Pond Liner HDPE Impermeable Membrane for regulated containment projects.

Core Pain Points and Engineering Solutions

Pain Point: Seam leakage risk

Solution: Specify double-track welding and air channel testingPain Point: Stress cracking over time

Solution: Require stress crack resistance testing dataPain Point: UV degradation during storage

Solution: Check carbon black and outdoor exposure limitsPain Point: Thickness inconsistency

Solution: Demand roll-by-roll thickness scan reports

Risk Warnings and Avoidance Measures

Do not accept recycled-content liners for critical landfill cells unless approved

Verify batch test reports match roll numbers

Control on-site welding temperature and speed

Require installer welding certification

Inspect subgrade to prevent puncture damage

Improper handling can negate the barrier performance of Landfill Pond Liner HDPE Impermeable Membrane.

Procurement Selection Guide

Define liner thickness based on risk category

Specify smooth or textured surface requirement

Request full mechanical and aging test reports

Verify resin source and virgin content

Review welding method compatibility

Check roll width and transport limits

Include field QA/QC testing in contract

Require sample roll for weld trials

Engineering Case Scenario

A regional landfill expansion project installed a 2.0 mm Landfill Pond Liner HDPE Impermeable Membrane over a compacted subgrade and geotextile cushion. Double hot-wedge welds were tested with air pressure channels and vacuum boxes. Third-party inspection verified seam strength and thickness compliance. The containment cell passed leakage testing before commissioning.

FAQ — Landfill Pond Liner HDPE Impermeable Membrane

What thickness is common for landfill use?

1.5–2.5 mm is frequently specified.

Is textured surface required?

Used on slopes for friction stability.

Can recycled HDPE be used?

Usually avoided in critical cells.

How are seams tested?

Air pressure and vacuum methods.

What welding methods are typical?

Hot wedge and extrusion welding.

Does temperature affect welding?

Yes, parameters must be adjusted.

Is a cushion layer needed?

Commonly geotextile underlay is used.

How long is service life?

Often several decades when protected.

Are factory tests sufficient?

Field QA/QC is still required.

Can it resist chemicals?

HDPE shows broad chemical resistance.

Request Technical Data and Samples

For landfill and containment projects, request full Landfill Pond Liner HDPE Impermeable Membrane technical datasheets, roll test reports, welding guides, and project samples for engineering validation and contractor trials.

E-E-A-T Author Qualification Statement

This article is prepared from a geosynthetics engineering and construction procurement perspective, based on widely used geomembrane standards, field installation practices, and containment project quality control requirements.