60 mil HDPE Liner Landfill Impermeable Geomembrane

The global demand for 60 mil HDPE Liner Landfill Impermeable Geomembrane has increased sharply as governments strengthen environmental protection policies and landfill owners prioritize long-term containment safety. With stricter regulations on hazardous waste disposal, groundwater protection, and leachate control, geomembrane systems have become essential components in modern waste management infrastructure.

The 60 mil thickness specification remains one of the most widely used standards in waste containment projects, balancing high mechanical strength, cost efficiency, and installation flexibility. Interest is also rising in related long-tail keywords, such as “HDPE geomembrane for landfill base lining”, “impermeable liner for waste containment”, “geomembrane landfill cap systems”, “1.5mm HDPE liner substitutes”, and “environmental protection composite liner solutions”.

Introduction: Growing Demand for 60 mil HDPE Liner in Landfill Engineering

The global demand for 60 mil HDPE Liner Landfill Impermeable Geomembrane has increased sharply as governments strengthen environmental protection policies and landfill owners prioritize long-term containment safety. With stricter regulations on hazardous waste disposal, groundwater protection, and leachate control, geomembrane systems have become essential components in modern waste management infrastructure.

The 60 mil thickness specification remains one of the most widely used standards in waste containment projects, balancing high mechanical strength, cost efficiency, and installation flexibility. Interest is also rising in related long-tail keywords, such as “HDPE geomembrane for landfill base lining”, “impermeable liner for waste containment”, “geomembrane landfill cap systems”, “1.5mm HDPE liner substitutes”, and “environmental protection composite liner solutions”.

Global Market Landscape and Industry Growth

The global geomembrane market is projected to grow at a CAGR of 7%–10% over the next five years, driven mainly by infrastructure upgrades, waste facility expansion, and increased government investment in environmental remediation. Regions such as North America, the Middle East, Africa, and Southeast Asia continue to expand landfill capacity, reinforcing the demand for 60 mil HDPE liner landfill impermeable geomembrane systems.

Emerging economies face rapid urbanization, producing higher volumes of municipal solid waste, industrial waste, and mining byproducts. As a result, the adoption of multi-layer containment systems—using HDPE geomembranes, geosynthetic clay liners, drainage composites, and protective geotextiles—is accelerating in these regions.

Technical Specifications and Key Performance Indicators

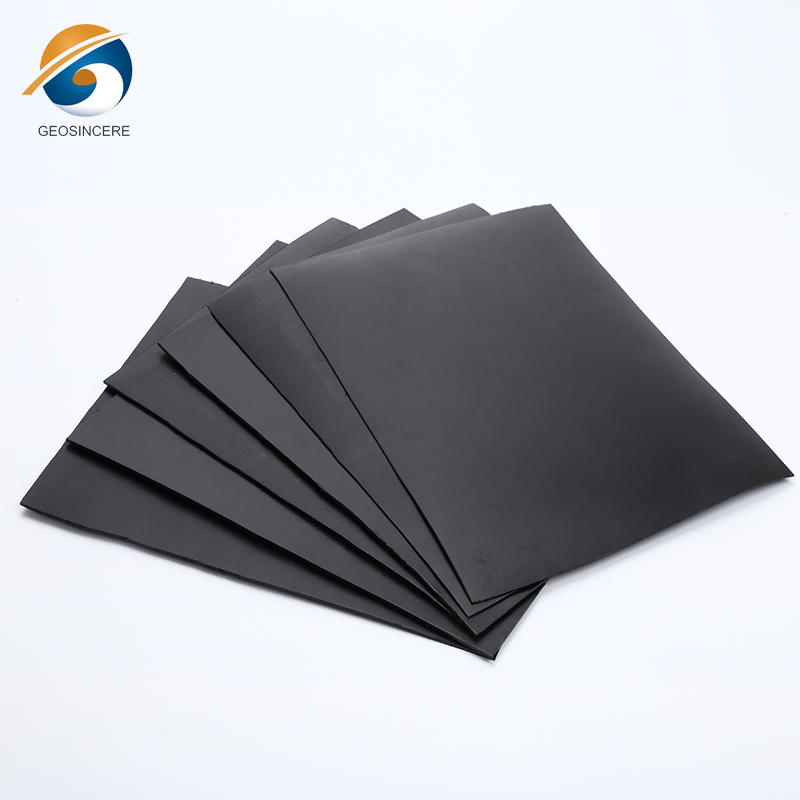

The 60 mil HDPE liner landfill impermeable geomembrane must comply with strict international engineering standards. Critical performance characteristics include:

• Thickness: 1.5 mm (nominal)

• Tensile strength at yield: 15–20 kN/m depending on resin formulation

• Break elongation: above 700%

• Puncture resistance: designed to resist rock and subgrade pressure

• Carbon black content: 2%–3% for long-term UV stability

• Permeability: ≤ 1×10⁻¹⁴ cm/s

• Chemical resistance: strong resistance to acids, alkalis, salts, organic compounds, and leachate ingredients

These specifications ensure structural reliability, impermeability, and durability throughout the lifespan of modern landfill facilities.

Product Structure and Engineering Composition

A standard 60 mil HDPE liner features a dense, high-crystallinity polyethylene matrix designed to deliver high resistance to stress cracking, chemical attack, and environmental aging. Depending on project requirements, surfaces may be smooth or textured to enhance friction performance against soils or geosynthetic layers.

The liner structure may include single-side texturing, double-side texturing, or smooth-surface configurations. Textured HDPE geomembrane variants provide improved interface friction, making them suitable for steep-slope landfill designs and composite bottom liner systems.

Manufacturing Process and Quality Control

The production of landfill-grade geomembranes requires precision manufacturing and continuous quality monitoring:

1. Resin selection and blending with additives such as antioxidants and carbon black

2. Extrusion through advanced blown-film or flat-die lines

3. Cooling, thermal stabilization, and dimensional calibration

4. Surface texturing where required

5. Automated laser inspection of thickness uniformity

6. Mechanical testing including tensile, tear, puncture, and peel strength

7. Packaging and roll labeling for traceable logistics

International procurement teams frequently request comprehensive QC documentation such as factory test reports, third-party certifications, and conformance results following standards like GRI-GM13.

Application Process: Landfill Containment and Environmental Protection

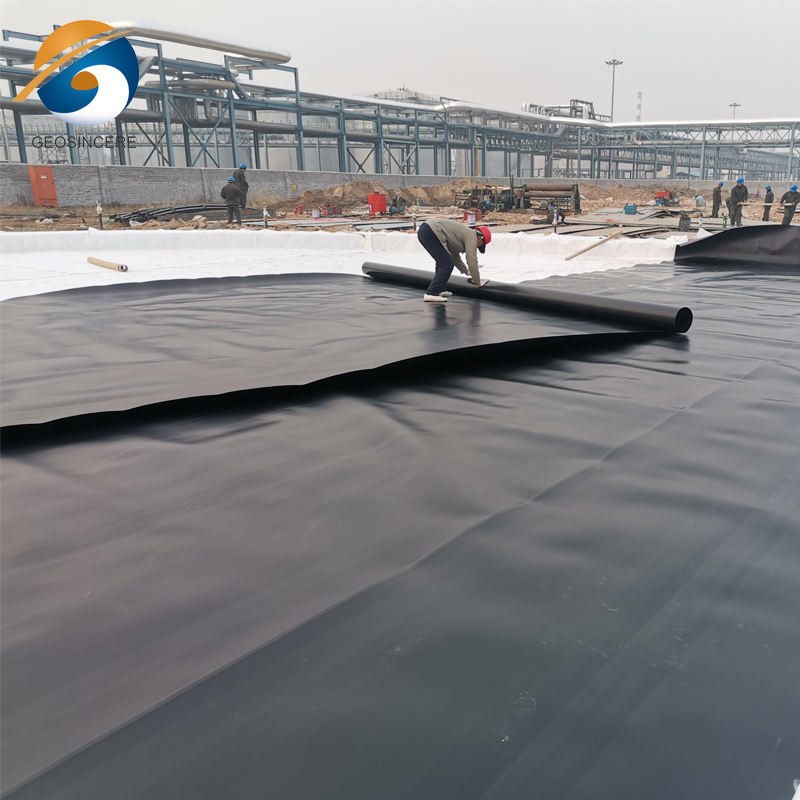

The installation of 60 mil HDPE liner landfill impermeable geomembrane typically follows a multi-step engineering sequence:

• Subgrade preparation and compaction

• Placement of cushioning geotextile

• Deployment of HDPE geomembrane rolls using specialized lifting equipment

• Field welding with hot wedge or extrusion guns

• Non-destructive and destructive seam testing

• Installation of drainage composites or leachate collection layers

• Quality documentation and construction acceptance testing

This installation workflow ensures full containment efficiency and compliance with regulatory performance criteria.

Industry Trends Shaping Global Procurement

Several key trends are influencing international purchasing decisions:

• Shift toward thicker liners (80 mil, 100 mil) for hazardous waste projects

• Increased demand for composite liner systems combining geomembrane and GCL

• Strong preference for textured surfaces in engineered slopes

• Rising focus on long-term UV stability for exposed applications

• Broader adoption of digital QA/QC monitoring systems during installation

Procurement teams are also increasingly evaluating sustainability indicators such as recycled polymer usage, energy-efficient production, and environmental compliance certifications.

Buyer Preferences and Procurement Pain Points

International buyers consistently prioritize the following aspects when sourcing landfill impermeable geomembranes:

• Verified compliance with GRI, ASTM, or ISO standards

• Reliable compatibility with leachate and chemical contamination

• Strong track record in landfill and mining containment projects

• Stable lead times and consistent production capacity

• Technical support for welding, testing, and installation

However, several pain points frequently appear in global procurement cycles:

• Variability in material thickness or resin purity

• Insufficient technical documentation for government approval

• Concerns regarding texturing uniformity in slope applications

• Inconsistent packaging leading to deformation during shipping

• Lack of engineering support for large-scale, multi-layer landfill designs

To mitigate these challenges, We recommend requesting full QC reports, project references, and welding guidance before finalizing orders.

Conclusion: Ensuring Reliable Landfill Containment with Advanced Geomembrane Technology

The 60 mil HDPE liner landfill impermeable geomembrane remains a critical component in environmental containment systems, balancing mechanical performance, chemical resistance, and cost efficiency. As global waste volumes rise and environmental regulations tighten, the importance of reliable geomembrane solutions continues to grow.

We support international landfill developers, engineering firms, and contractors with professional technical documentation, sample evaluation, and customized specifications tailored to project needs. Contact us to request detailed quotes, engineering reports, or free samples for upcoming landfill or waste containment projects.

FAQs

1. Is 60 mil HDPE liner suitable for municipal solid waste landfills?

Yes. It meets international performance requirements and is widely used in MSW landfill base liners and caps.

2. Can 60 mil HDPE geomembrane be used on steep slopes?

Textured variants are designed for improved friction performance, making them suitable for engineered slopes.

3. How is the liner welded during installation?

Hot wedge welding and extrusion welding are standard methods, followed by vacuum and destructive seam tests.

4. What quality documents should be provided by suppliers?

ASTM test reports, GRI-GM13 compliance results, raw material certificates, and roll traceability labels.

References:

• Geosynthetic Research Institute (GRI) GM13 Standard

• U.S. EPA guidelines for landfill liner system design