Water Storage Tank Liner High Density Polyethylene Membrane

Manufacturing Process

Raw Material Preparation: HDPE resin blended with carbon black and stabilizers using an automated batching system.

Extrusion Process: High-precision extruders melt and press the mixture into uniform sheets.

Calendering and Stretching: Ensures consistent thickness and molecular orientation.

Cooling Section: Controlled cooling to prevent internal stress deformation.

Surface Finishing: Optional texturing using ceramic rollers.

Quality Inspection: Tensile testing, aging tests, pinhole tests, and dimension checks.

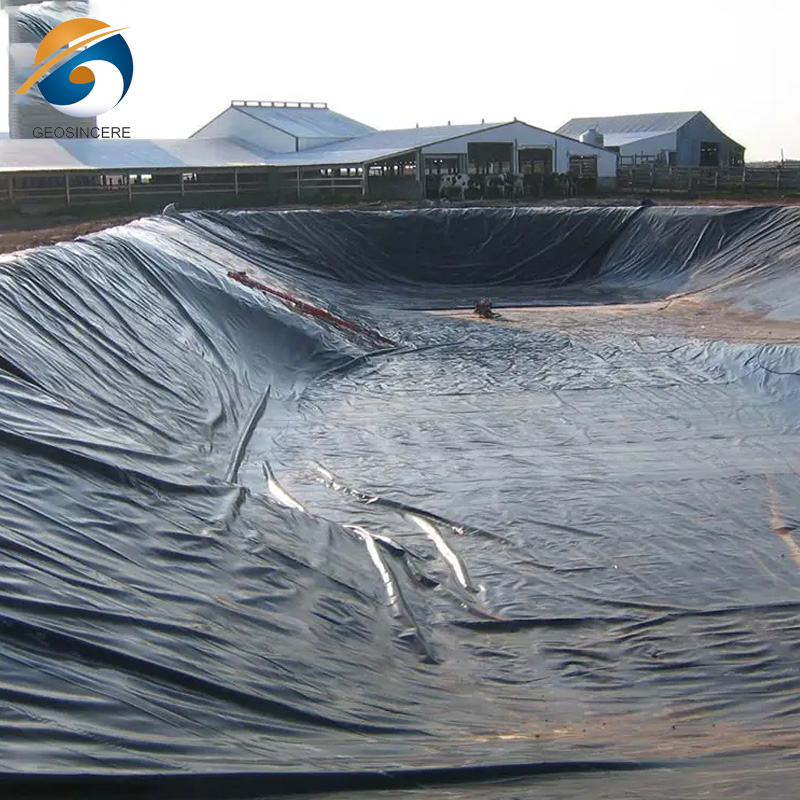

Water Storage Tank Liner High Density Polyethylene Membrane Definition

Water Storage Tank Liner High Density Polyethylene Membrane is an engineered geomembrane used to provide long-term waterproofing, chemical resistance, and structural containment inside industrial and municipal water tanks. It ensures leak prevention, corrosion isolation, and compliance with international water storage standards.

Technical Parameters and Specifications

| Parameter | Specification Range |

|---|---|

| Thickness | 0.75–2.0 mm |

| Density | ≥ 0.94 g/cm³ |

| Tensile Strength | ≥ 25 MPa |

| Elongation at Break | ≥ 600% |

| Puncture Resistance | ≥ 900 N |

| Carbon Black Content | 2.0%–3.0% |

| Service Life | 15–25 years depending on UV exposure |

| Operating Temperature | -40°C to +60°C |

Structure and Material Composition

Base Polymer: Premium-grade high density polyethylene resin.

Carbon Black Layer: UV stabilizer providing long-term outdoor durability.

Antioxidant Additives: Ensures resistance to thermal oxidation during operation.

Molecular Chain Alignment: Enhances flexibility and tensile performance.

Surface Treatment: Single- or double-sided textured options for enhanced friction.

Manufacturing Process

Raw Material Preparation: HDPE resin blended with carbon black and stabilizers using an automated batching system.

Extrusion Process: High-precision extruders melt and press the mixture into uniform sheets.

Calendering and Stretching: Ensures consistent thickness and molecular orientation.

Cooling Section: Controlled cooling to prevent internal stress deformation.

Surface Finishing: Optional texturing using ceramic rollers.

Quality Inspection: Tensile testing, aging tests, pinhole tests, and dimension checks.

Industry Comparison

| Material | Lifespan | Chemical Resistance | Installation Difficulty | Cost Level |

|---|---|---|---|---|

| HDPE Membrane | 15–25 years | Excellent | Moderate | Medium |

| PVC Liner | 8–12 years | Good | Easy | Low |

| Rubber EPDM | 12–18 years | Medium | Moderate | High |

| Fiberglass Coating | 10–15 years | Medium | High | High |

Application Scenarios

Industrial EPC Projects: Firewater storage tanks, process water tanks.

Municipal Construction: Potable water reservoirs, emergency water storage.

Agricultural Engineering: Irrigation tanks, aquaculture basins.

Commercial Installers & Distributors: Prefabricated steel plate tanks, concrete tanks.

Core Pain Points and Solutions

Pain Point 1: Leakage due to tank wall cracks.

Solution: HDPE Membrane forms a continuous waterproof barrier independent of tank structure.Pain Point 2: Chemical corrosion in industrial water systems.

Solution: Material provides high resistance to acids, alkalis, and salts.Pain Point 3: UV degradation in outdoor installations.

Solution: Carbon black stabilization delays aging and ensures long-term performance.Pain Point 4: Difficult on-site installation.

Solution: Hot-wedge welding machines provide clean seams with high tensile strength.

Risk Warnings and Mitigation Guidelines

Improper welding may cause seam failure—use certified welding technicians.

Direct installation on sharp objects may puncture the membrane—require geotextile cushioning.

Excessive UV exposure shortens lifespan—select higher carbon black content for outdoor tanks.

Poor substrate cleaning leads to liner wrinkles—ensure dry, smooth installation surfaces.

Procurement and Selection Guide

Confirm tank type (steel, concrete, prefabricated structure).

Determine required membrane thickness based on liquid type.

Evaluate UV exposure and select appropriate carbon black dosage.

Check supplier certifications (ISO, CE, ASTM testing reports).

Review welding equipment compatibility and installation method.

Request mechanical performance and aging test data.

Verify project references in similar industrial sectors.

Engineering Case Study

A 3,500 m³ industrial firewater tank in a petrochemical facility required corrosion isolation and long-term leak protection. Engineers selected a 1.5 mm Water Storage Tank Liner High Density Polyethylene Membrane. The EPC contractor installed a geotextile buffer layer followed by HDPE sheets using automated hot-wedge welding. Seam testing achieved over 90% joint efficiency. The system passed hydrostatic testing and has been operating leak-free for over four years.

FAQ

What is the standard thickness for industrial tanks? — Typically 1.0–1.5 mm.

Can HDPE membrane be used for potable water? — Yes, when certified to drinking-water standards.

How long can it last outdoors? — 15–20 years depending on UV intensity.

Is welding required? — Yes, for a fully sealed containment system.

Can it resist acidic liquids? — Suitable for mild to moderate chemical environments.

Do tanks need surface preparation? — Yes, remove debris and sharp objects.

Can it be repaired? — Yes, using hot-air weld patches.

Is textured membrane necessary? — Recommended for sloped surfaces.

Does temperature affect performance? — Operational range is -40°C to +60°C.

What testing is required? — Non-destructive seam tests (air channel or vacuum box).

Request a Quote / Technical Data / Engineering Sample

For technical specifications, engineering samples, or project-based quotations for Water Storage Tank Liner High Density Polyethylene Membrane, contact our engineering support team for detailed documentation and professional guidance.

E-E-A-T Author Credentials

This article is authored by a senior materials engineer with over 12 years of experience in geomembranes, industrial waterproofing systems, and water storage engineering projects. The content is based on internationally recognized standards and field-validated installation methodologies.