1mm HDPE Liner

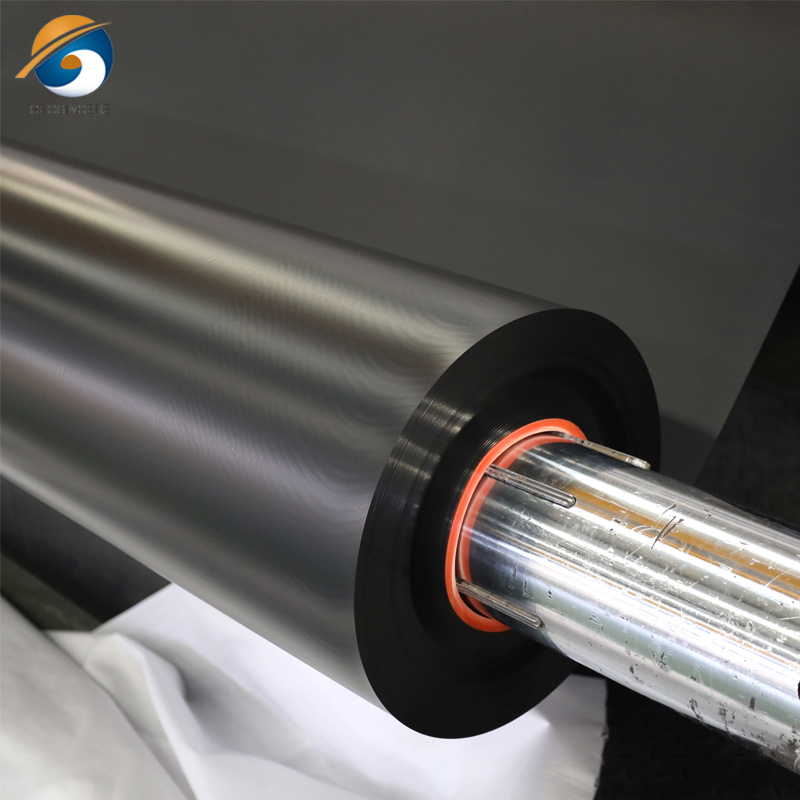

The 1mm HDPE liner is a high-performance geomembrane manufactured from premium high-density polyethylene resin, designed for reliable waterproofing and anti-seepage protection in a wide range of engineering and environmental applications. It offers excellent durability, chemical resistance, and long-term performance, making it ideal for demanding outdoor and industrial projects.

Specifications:

Thickness: 1.0 mm

Material: High Density Polyethylene (HDPE)

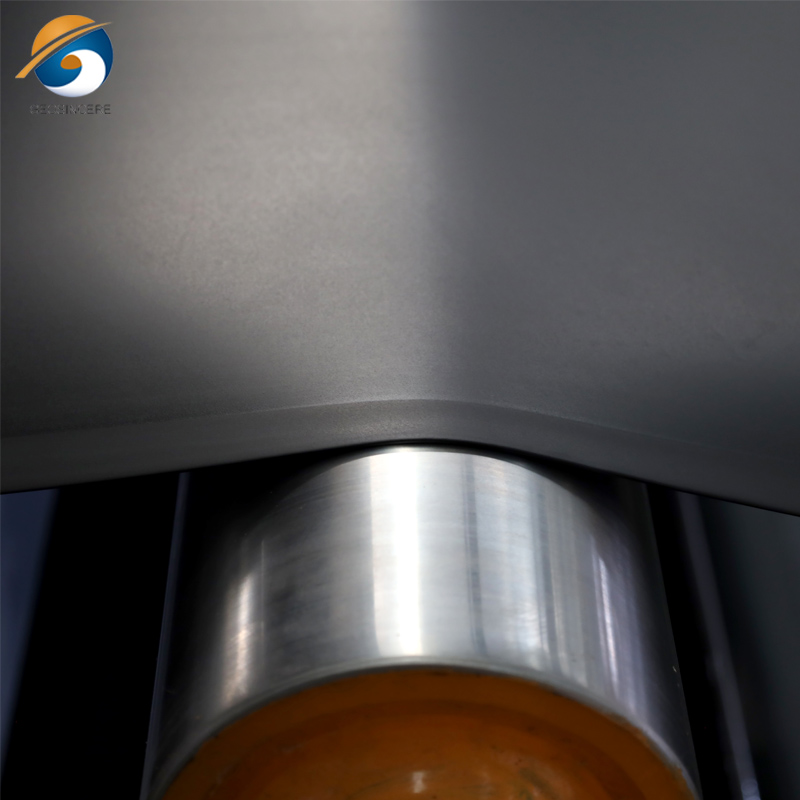

Surface: Smooth / Textured / Double Textured

Standard Width: 3 m – 10 m (customizable)

Roll Length: 50 m – 200 m (customizable)

Color: Black (other colors available upon request)

Density: ≥ 0.94 g/cm³

Standards: ASTM GRI-GM13 / GM17 (optional)

Service Life: Up to 30–50 years under proper installation

The 1mm HDPE liner is a high-quality geomembrane manufactured from premium high-density polyethylene resin using advanced extrusion technology. It is engineered to deliver reliable waterproofing and anti-seepage protection for a wide range of civil, environmental, and industrial applications. With uniform thickness and stable material properties, the hdpe pond liner offers excellent impermeability, mechanical strength, and long-term durability. It performs well under harsh conditions, including UV exposure, chemical contact, and temperature variations, making it suitable for both above-ground and buried installations. Easy to weld and install, the 1mm HDPE liner helps ensure secure seams and consistent performance, providing a cost-effective and dependable solution for modern engineering projects.

1. 1mm HDPE Liner Material & Manufacturing

1.1 Premium Raw Materials

Produced from 100% virgin or high-grade HDPE resin, the hdpe geomembrane delivers stable physical and chemical properties, ensuring high purity, strength, and long-term reliability.

1.2 Advanced Manufacturing Technology

Manufactured using advanced extrusion technology and precise temperature control, the production process guarantees consistent material structure and performance.

1.3 Uniform Thickness Control

Strict thickness control during production ensures uniform thickness across the entire roll, reducing weak points and improving overall impermeability.

1.4 Smooth and Consistent Surface Quality

The geomembrane sheet features a smooth, defect-free surface, enhancing welding efficiency and seam strength during installation.

1.5 Stable and Consistent Performance

Every roll is high density polyethylene pond liner produced under controlled conditions to ensure consistent mechanical performance, chemical resistance, and durability throughout the product’s service life.

2. 1mm HDPE Liner Performance & Durability

2.1 Ultra-Low Permeability

The 1mm HDPE liner provides exceptionally low permeability, effectively preventing the migration of liquids and gases, ensuring reliable containment and environmental protection.

2.2 High Tensile Strength

It exhibits excellent tensile strength, enabling the polyethylene pond liners to resist stress and deformation under soil pressure and external loads.

2.3 Superior Elongation Properties

High elongation at break allows the hdpe liner pond to accommodate ground movement and settlement without cracking or tearing.

2.4 Strong Puncture and Tear Resistance

The high density polyethylene liner offers outstanding puncture and tear resistance, reducing the risk of damage during installation and long-term service.

2.5 UV Resistance for Outdoor Exposure

Enhanced UV resistance ensures stable performance under prolonged sunlight exposure, making it suitable for outdoor applications.

2.6 Oxidation and Aging Resistance

Strong resistance to oxidation and aging extends the service life of the high density polyethylene geomembrane, maintaining its physical properties over time.

3. 1mm HDPE Liner Chemical & Environmental Resistance

3.1 Broad Chemical Resistance

The 1mm hdpe geo membrane is highly resistant to acids, alkalis, salts, and most organic chemicals, ensuring long-term stability even in harsh chemical environments.

3.2 Ideal for Industrial and Environmental Applications

Its chemical resistance makes it suitable for use in landfills, wastewater treatment plants, mining operations, and industrial containment projects.

3.3 Non-Toxic and Environmentally Safe

The geomembrane pond liner is made from environmentally safe HDPE material, non-toxic and inert, making it safe for use in projects involving water, soil, and ecosystems.

3.4 Corrosion and Leachate Protection

It effectively prevents chemical leaching and soil contamination, providing a reliable barrier for environmental protection projects.

3.5 Long-Term Stability

The hdpe geomembrane liner material maintains its chemical properties over time, ensuring durable performance under continuous chemical exposure.

4. 1mm HDPE Liner Application Versatility

4.1 Pond Lining

Ideal for fish ponds, irrigation ponds, and ornamental ponds, the hdpe geomembrane sheet ensures effective water containment and prevents seepage.

4.2 Reservoirs and Canals

Provides a durable barrier for water reservoirs and irrigation canals, protecting against leakage and erosion.

4.3 Tailings Dams and Mining Projects

Used in tailings storage facilities and mining operations, offering reliable containment of industrial liquids and residues.

4.4 Landfill Liners

Effectively isolates waste in landfill projects, preventing contamination of soil and groundwater.

4.5 Biodigesters

Compatible with biogas and biodigester systems, resisting chemical corrosion and maintaining long-term integrity.

4.6 Aquaculture Farms

Supports sustainable aquaculture projects, providing a safe and impermeable lining for fish and shrimp farming.

4.7 Environmental Protection Projects

Suitable for wetlands, artificial lakes, and soil remediation projects, helping to safeguard natural resources.

4.8 Flexible Engineering Solutions

Its versatility allows use in civil engineering, agriculture, and industrial projects, adapting to various terrains and environmental conditions.

5. 1mm HDPE Liner – Quality Standards & Customization

5.1 Compliance with International Standards

The 1mm HDPE liner can be manufactured according to ASTM, GRI-GM13 / GM17, ISO, and other international standards, ensuring consistent quality, safety, and reliability for global projects.

5.2 Custom Roll Widths

Roll widths can be customized, typically ranging from 3 m to 10 m, to suit project-specific installation needs and minimize on-site seams.

5.3 Custom Roll Lengths

Roll lengths are adjustable, commonly 50 m to 200 m per roll, providing flexibility for different construction scales and reducing installation time.

5.4 Surface Texture Options

Available in smooth, textured, or double-textured surfaces, allowing adaptation for various slope conditions, friction requirements, and drainage efficiency.

5.5 Color Customization

While black is standard, custom colors can be provided upon request for aesthetic or functional purposes.

5.6 Thickness & Tolerance Control

Manufactured with precise 1mm thickness control and tight tolerance, ensuring uniformity and consistent performance across the entire roll.

5.7 Tailored Solutions for Projects

Other specifications, such as density, reinforcement, or additive requirements, can be customized to meet unique project conditions and regulatory needs.

6. 1mm HDPE Liner Installation & Welding

6.1 Easy Handling and Installation

The 1mm hdpe liner sheet is lightweight and flexible, allowing for efficient transport, positioning, and deployment on-site, even in challenging terrains.

6.2 Welding Compatibility

Compatible with hot wedge welding, extrusion welding, and other standard HDPE welding techniques, ensuring strong, durable, and leak-proof seams.

6.3 Smooth and Textured Surface Options

Available in smooth, textured, or double-textured surfaces, which help optimize friction, slope stability, and seam adhesion based on specific project requirements.

6.4 Seam Strength and Integrity

Professional welding ensures uniform seam strength, providing complete system integrity and minimizing the risk of leakage.

6.5 On-Site Flexibility

The 40 mil hdpe liner can be cut, shaped, and joined on-site to accommodate slopes, corners, curves, and irregular surfaces without compromising performance.

6.6 Installation Guidance

Recommended installation includes proper surface preparation, seam testing, and protective measures to maximize the liner’s service life and long-term reliability.

7. 1mm HDPE Liner Additional Functional Features

7.1 Textured Surface Benefits

The textured liner is available with textured or double-textured surfaces, which improve friction and grip on slopes, reducing the risk of sliding and enhancing slope stability in steep or uneven terrain.

7.2 Heat and Cold Resistance

Engineered to withstand extreme temperatures, the 1mm HDPE liner maintains its physical and mechanical properties under both high heat and freezing conditions, ensuring reliable performance in diverse climates.

7.3 Customization for Special Projects

Special additives, such as UV stabilizers, anti-aging agents, or flame retardants, can be incorporated to meet the requirements of unique environmental conditions or regulatory standards.

7.4 Enhanced Seam Performance

Textured and treated surfaces can improve welding and seam strength, ensuring long-term integrity even in challenging installation scenarios.

7.5 Chemical & Abrasion Resistance Enhancements

Additional functional treatments can increase resistance to chemical exposure, abrasion, and mechanical wear, making the liner suitable for industrial, mining, or landfill applications.

7.6 Flexibility for Complex Terrain

Specially engineered liners retain flexibility and formability, allowing installation on curved, irregular, or uneven surfaces without compromising performance.

8. 1mm HDPE Liner Customer Support & Services

8.1 Technical Support

We provide professional guidance on welding, installation, and construction techniques, ensuring that customers can achieve optimal performance and seam integrity during the project.

8.2 On-Site Training

Our team can offer on-site training to help clients quickly master proper installation methods, seam welding, and handling procedures, reducing installation errors and project delays.

8.3 After-Sales Service

Comprehensive after-sales support includes quality assurance, product replacement policies, maintenance guidance, and troubleshooting advice, ensuring long-term satisfaction.

8.4 Customized Consultation

We provide tailored project consultation and design advice, helping clients select the right thickness, surface texture, and installation method for their specific requirements.

8.5 Documentation & Support Materials

Customers receive installation manuals, welding guides, and technical datasheets, making it easier to train personnel and maintain compliance with project standards.

8.6 Rapid Response Service

Our support team ensures timely responses to inquiries, on-site issues, and emergency support, minimizing downtime and ensuring smooth project execution.

Summary

The 1mm HDPE liner offers excellent waterproofing, chemical resistance, durability, and versatile application for ponds, reservoirs, canals, landfills, biodigesters, and more. With customizable specifications, reliable installation options, and comprehensive customer support, it provides a cost-effective and long-lasting solution for a wide range of engineering and environmental projects. Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) is your trusted partner for high-quality HDPE liners, delivering consistent performance, factory-direct pricing, and professional guidance for every project.