Geomembrane LDPE

Geomembrane LDPE (Low-Density Polyethylene) is a bendy and long lasting water-resistant barrier extensively used in civil engineering, environmental protection, and agricultural projects. It is manufactured from wonderful virgin LDPE resin with superior extrusion or calendaring technology, making sure extremely good elongation, chemical resistance, and long-term overall performance in more than a few area conditions.

- Geomembrane LDPE Thickness Range: 0.2 mm to 3.0 mm

- High Flexibility: Ideal for purposes requiring bending and shaping barring cracking.

- Excellent Chemical Resistance: Withstands acids, alkalis, and a vast vary of industrial chemicals.

- UV & Weather Resistant: Maintains integrity beneath extended solar publicity and harsh climates.

- Ease of Installation: Lightweight and adaptable for on-site welding or fastening.

Geomembrane LDPE (Low-Density Polyethylene) is a premium, relatively bendy water-proof lining fabric engineered to grant long-lasting containment options in civil, environmental, industrial, and agricultural projects. Produced from terrific virgin LDPE resin, it provides outstanding elongation, tensile strength, and chemical resistance. Its special low-density molecular shape ensures optimal flexibility besides compromising durability, making it best for initiatives the place adaptability and waterproofing overall performance are critical.

1. Geomembrane LDPE Material Properties and Composition

Manufactured the use of superior extrusion or calendaring processes, LDPE pond liner is handy in easy or textured finishes to go well with one of a kind engineering needs. The formula accommodates UV stabilizers, antioxidants, and anti-aging components to make sure long-term stability, even below harsh environmental conditions. This mixture of high-grade uncooked substances and modern-day manufacturing technological know-how effects in a geomembrane that offers dependable performance, prolonged carrier life, and steady excellent in stressful applications.

2. Performance and Properties of Geomembrane LDPE

2.1 Geomembrane LDPE Physical Performance

- Tensile Strength: High tensile resistance ensures structural steadiness beneath mechanical stress.

- Elongation at Break: LDPE liner typically exceeds 500%, offering exceptional flexibility for irregular surfaces and agreement areas.

- Puncture Resistance: Withstands have an impact on and sharp object penetration, making sure long-term integrity in rugged environments.

- Tear Resistance: Maintains sealing overall performance even when subjected to anxiety or mechanical damage.

2.2 Geomembrane LDPE Chemical Resistance

- Acids: Excellent resistance to hydrochloric acid, sulfuric acid, nitric acid (up to average concentrations).

- Alkalis: Strong resistance to sodium hydroxide, potassium hydroxide, and different bases.

- Salts: Stable in saline water and a number salt solutions.

- Organic Compounds: Good resistance to many alcohols and glycols; constrained resistance to sturdy solvents such as fragrant hydrocarbons.

- Resistant to a extensive vary of chemicals, including:

Ideal for purposes in wastewater treatment, mining, and chemical containment.

2.3 Geomembrane LDPE Temperature Performance

- Low-Temperature Flexibility: Remains pliable at temperatures as low as -60°C, stopping brittleness in bloodless climates.

- High-Temperature Stability: Retains mechanical and waterproofing overall performance up to +60°C in non-stop exposure.

- Thermal Expansion/Contraction: Low coefficient of thermal enlargement minimizes deformation in temperature fluctuations.

2.4 Geomembrane LDPE UV and Weather Resistance

- Formulated with high-grade UV stabilizers to forestall degradation from extended daylight exposure.

- Tested for >5,000 hours of accelerated weathering with minimal loss of mechanical strength.

- Resistant to ozone, oxidation, and common atmospheric aging, making it appropriate for long-term out of doors installations.

3. LDPE Geomembrane Technical Specifications

3.1 Geomembrane LDPE Thickness:

Available from 0.2 mm to 3.0 mm to meet numerous engineering requirements.

Thinner geomembrane liner is appropriate for brief or light-duty containment, whilst thicker membrane provide greater mechanical energy and puncture resistance for heavy-duty purposes such as mining or landfill liner.

Manufactured in accordance with ASTM D5199 for correct thickness measurement.

3.2 Geomembrane LDPE Width:

Supplied in geomembrane pond liner rolls up to eight meters extensive (seamless), lowering the range of area seams and enhancing set up efficiency.

Wide-width manufacturing minimizes practicable leakage factors and speeds up deployment on large-scale projects.

3.3 Geomembrane LDPE Length:

Standard roll size stages from 50 to 200 meters, with customized lengths on hand upon request.

Longer geomembrane sheet assist decrease welding time and labor expenses in giant installations.

3.4 Geomembrane LDPE Color Options:

- Black Geomembrane LDPE (standard): Provides most UV resistance and light-blocking performance.

- White Geomembrane LDPE : Reflects sunlight, supporting to manage substrate temperature and limit thermal expansion.

- Green Geomembrane LDPE : Offers aesthetic mixing with herbal environment in landscaping or environmental applications.

- Dual-Colored Layers Geomembrane LDPE : Combines distinctive colours on every aspect for convenient set up orientation and inspection.

3.5 Geomembrane LDPE Surface Finish:

- Smooth Geomembrane LDPE : Ensures excessive impermeability and is less difficult to clean.

- Textured Geomembrane LDPE : Improves friction between the geomembrane and soil or geotextile, improving slope balance in embankments and landfill sidewalls.

3.6 Geomembrane LDPE Compliance Standards:

- ASTM D5199 – Standard Test Method for Measuring Nominal Thickness of Geomembranes.

- ASTM D6693 – Standard Test Method for Tensile Properties of Geomembranes.

- ISO 9001 – Quality administration certification making sure steady manufacturing standards.

- GRI-GM – Geosynthetic Research Institute requirements for polyethylene geomembranes overall performance and durability.

4. Main Advantages of Geomembrane LDPE

4.1 Geomembrane LDPE - Exceptional Flexibility

LDPE geomembrane presents magnificent flexibility, permitting it to adapt without difficulty to irregular surfaces, slopes, and complex structures. This property ensures a tight suit besides stress cracking, making it best for tasks that require lining over uneven terrain or settlement-prone areas.

4.2 Geomembrane LDPE - Excellent Waterproofing

The membrane gives a totally impermeable barrier towards water, oil, and most industrial chemicals. This makes it an high-quality answer for containment structures such as reservoirs, chemical storage areas, and landfill liner, making sure no leakage or seepage takes place over the lengthy term.

4.3 Geomembrane LDPE - High Durability

Designed to stand up to mechanical stress, LDPE impermeable geomembrane resists punctures, tears, and abrasion. Its strong composition permits it to operate reliably in difficult environments, which includes these with coarse subgrades, heavy tools traffic, or fluctuating loads.

4.4 Geomembrane LDPE - UV and Weather Resistance

Formulated with top class UV stabilizers and anti-aging additives, the material continues its mechanical power and sealing overall performance even after extended publicity to sunlight, ozone, and various climate conditions. This makes it appropriate for each everlasting out of doors installations and high-altitude projects.

4.5 Geomembrane LDPE - Customizable Dimensions

Available in a vary of thicknesses (0.2 mm to 3.0 mm), widths (up to eight meters), and roll lengths (50–200 meters), LDPE geomembrane can be tailor-made to meet precise assignment requirements. Options for easy or textured surfaces in addition increase its software versatility.

4.6 Geomembrane LDPE - Ease of Installation

Lightweight and effortless to handle, the polyethylene geomembranes permits for speedy deployment and environment friendly installation. It is wholly like minded with warmth welding techniques, enabling strong, leak-free seams that meet strict engineering specifications.

5. Market and Competitive Advantages of Geomembrane LDPE

5.1 Performance Comparison of Geomembrane LDPE and other Geomembranes

Compared to HDPE geomembrane, LDPE provides larger flexibility and ease of installation, making it perfect for tasks with irregular surfaces or requiring difficult lining work. While it has barely decrease tensile power than HDPE, it affords higher elongation properties. Against LLDPE Geomembrane, LDPE usually has comparable flexibility however provides greater softness for elevated handling. In assessment to PVC geomembrane, LDPE is extra resistant to environmental stress cracking and chemical degradation, whilst heading off the use of plasticizers that can leach out over time.

5.2 Geomembrane LDPE Cost-to-Lifespan Value

LDPE geomembrane can provide a sturdy stability between preliminary funding and long-term performance. Its average manufacturing value blended with prolonged carrier existence gives a favorable cost-performance ratio, specially in medium- to large-scale containment projects. Lower preservation necessities additionally make contributions to general financial savings over the product’s operational lifespan.

5.3 Geomembrane LDPE Global Market Applications

LDPE geomembranes are extensively adopted in worldwide markets for environmental protection, water conservation, mining, aquaculture, and industrial containment. Their adaptability to various regulatory necessities and task specs makes them a depended on desire for engineers and contractors worldwide.

5.4 Geomembrane LDPE Climate and Regional Suitability

Engineered to function in a extensive vary of climates, LDPE geomembrane retains flexibility and sealing overall performance in severe bloodless (down to -60°C) and continues balance in high-temperature environments (up to +60°C). Its UV and climate resistance make it appropriate for tropical, arid, temperate, and high-altitude regions, making sure dependable operation regardless of environmental conditions.

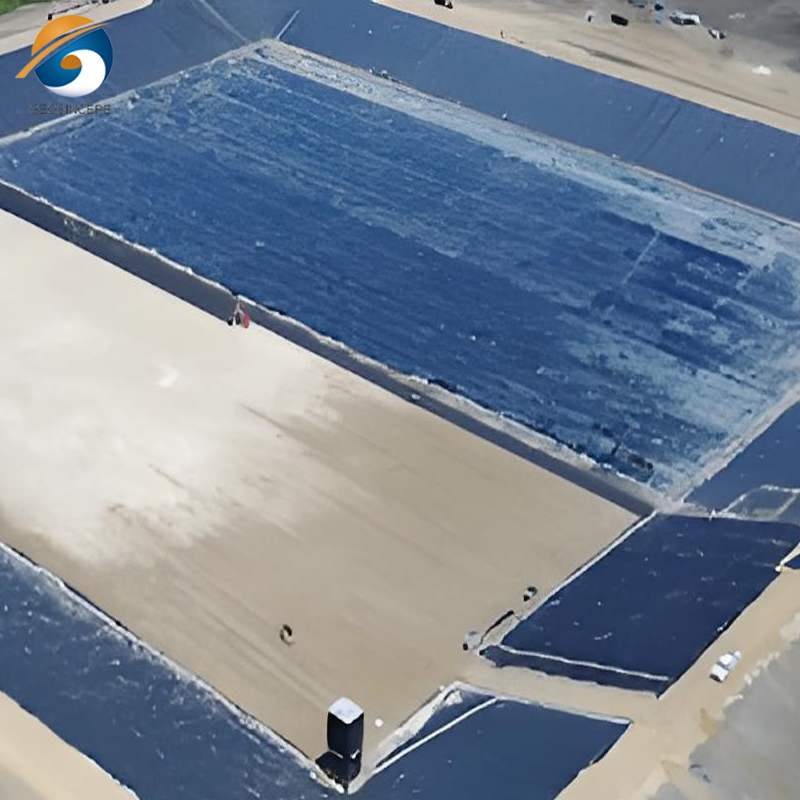

6. Geomembrane LDPE Project Cases and Applications

6.1 Successful Project Examples

Our LDPE geomembrane has been deployed correctly in severa high-profile tasks worldwide. For instance, in a latest landfill lining undertaking in Southeast Asia, a 1.5 mm thick LDPE membrane was once used to cowl over 150,000 m², supplying a durable, leak-proof barrier.

6.2 Industry-Specific Project Comparisons

- Geomembrane LDPE for Mining Applications: LDPE geomembranes are used for tailings ponds and heap leach pads, the place chemical resistance and puncture sturdiness are critical. Thicknesses usually vary from 1.0 to three mm to stand up to harsh mining environments.

- Geomembrane LDPE for Agricultural Uses: In agriculture, thinner membranes (0.5 to 1.2 mm) serve properly for pond linings, irrigation canals, and silage covers, emphasizing flexibility and ease of installation. The fabric helps forestall water loss and contamination, assisting sustainable farming practices.

These examples spotlight how LDPE geomembrane specs are tailor-made to meet wonderful region needs.

6.3 Customer Feedback and Usage Experience

Clients regularly commend the LDPE geomembrane for its dependable waterproofing, ease of installation, and long-term durability. Many observe decreased preservation charges and high quality containment even in harsh climates. Testimonials from engineers and undertaking managers underscore the material’s overall performance consistency throughout various applications.

7. Why Choose Our GEOSINCERE LDPE Geomembrane?

Choosing GEOSINCERE’s LDPE Geomembrane capacity partnering with a producer famend for optimal expertise, constant provide reliability, and rigorous pleasant control. Our geomembranes are engineered to supply long-term sturdiness and awesome performance, safeguarding the integrity of your undertaking and making sure environmental safety.

We make use of superior manufacturing technologies, thorough fine assurance processes, and provide customized client carrier to furnish geomembranes that meet and exceed the absolute best enterprise standards. Whether your assignment focuses on environmental protection, water conservation, or industrial containment, our LDPE geomembrane offers a proven, cost-effective, and reliable answer tailor-made to your unique needs.

For depended on first-rate and lasting performance, select GEOSINCERE Geosynthetics — your accomplice in sustainable geotechnical solutions.