Price of Geotextile

The geotextile industry has become a cornerstone of modern civil engineering and environmental management, driven by the demand for sustainable infrastructure, soil stabilization, and effective drainage solutions.

Globally, the market for geotextiles is projected to exceed USD 7 billion by 2030, fueled by road construction, railway development, and urban landscaping projects. Buyers increasingly seek products that combine durability, high filtration efficiency, and cost-effectiveness, making the understanding of geotextile pricing a critical aspect of procurement strategy.

Global Overview of the Geotextile Industry

The geotextile industry has become a cornerstone of modern civil engineering and environmental management, driven by the demand for sustainable infrastructure, soil stabilization, and effective drainage solutions.

Globally, the market for geotextiles is projected to exceed USD 7 billion by 2030, fueled by road construction, railway development, and urban landscaping projects. Buyers increasingly seek products that combine durability, high filtration efficiency, and cost-effectiveness, making the understanding of geotextile pricing a critical aspect of procurement strategy.

Factors Influencing the Price of Geotextile

Pricing of geotextiles is affected by multiple technical and market factors:

• Material type: Polypropylene (PP) and polyester (PET) are the most common, with PET generally commanding higher prices due to tensile strength.

• Fabric weight: Nonwoven geotextiles range from 100–500 g/m²; heavier fabrics cost more but offer superior performance.

• Manufacturing process: Needle punched, spunbond, or stitch-bonded processes impact production costs.

• Technical specifications: Tensile strength, elongation, puncture resistance, and permeability directly affect value.

• Market dynamics: Raw material prices, labor costs, and shipping logistics contribute to regional price variations.

Technical Parameters and Product Structure

Geotextiles are engineered for specific functions such as separation, filtration, reinforcement, and drainage. Nonwoven fabrics typically feature randomly oriented fibers mechanically bonded for high permeability, whereas woven geotextiles provide enhanced tensile strength for load-bearing applications.

Key technical parameters include:

• Tensile strength: 20–60 kN/m

• Elongation at break: 50–100%

• Water permeability: 100–500 L/m²/s

• Puncture resistance: ≥ 500 N

• UV stability: ≥ 500 hours

Manufacturing Process

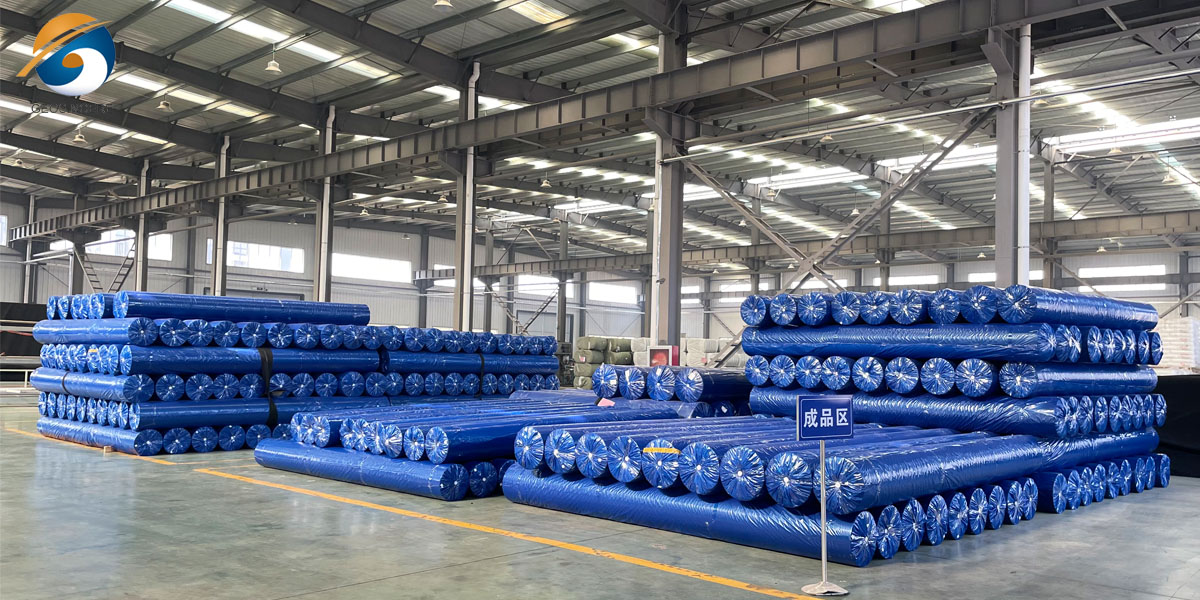

Geotextiles are produced using either woven or nonwoven methods. In nonwoven production, synthetic fibers are laid into a web, mechanically bonded via needle punching, and then heat-treated to ensure dimensional stability. Woven geotextiles involve interlacing warp and weft yarns to create high-strength sheets suitable for reinforcement purposes.

Stringent quality control includes testing for tensile strength, elongation, permeability, puncture resistance, and UV stability. Compliance with ASTM, ISO, and EN standards ensures suitability for international projects.

Applications Driving Demand

Geotextiles are widely used in civil and environmental engineering projects:

• Road and highway construction: Separation and stabilization of subgrade layers

• Railway construction: Ballast separation and drainage improvement

• Landfill and waste containment: Liner protection and filtration

• Landscaping and erosion control: Soil retention and water flow management

• Drainage systems: Prevention of soil clogging and efficient water movement

International Buyer Preferences and Pain Points

Global buyers prioritize product reliability, technical documentation, and cost-effectiveness. Typical concerns include:

• Consistent quality and compliance with international standards

• Long-term durability under environmental stress

• Ease of installation and customization to project-specific dimensions

• Transparent pricing and total lifecycle cost, not just initial purchase price

Pricing Trends and Market Insights

Current geotextile pricing ranges between USD 1–5 per square meter, depending on fabric type, weight, thickness, and technical specifications. Needle punched nonwoven fabrics typically occupy the mid-price range, offering a balance of cost and performance. Global price trends are influenced by polypropylene and polyester raw material costs, regional labor rates, and shipping logistics.

Buyers are increasingly adopting a total value approach, emphasizing durability and installation efficiency over upfront cost. Suppliers providing detailed technical documentation, certifications, and flexible order sizes often gain a competitive advantage.

Frequently Asked Questions (FAQ)

1. What factors affect the price of geotextile?

Material type, fabric weight, manufacturing process, technical specifications, and market conditions all influence pricing.

2. Can geotextile be customized for specific applications?

Yes, we provide custom weights, thicknesses, and roll sizes to meet project requirements.

3. How does geotextile improve soil stabilization and drainage?

By separating soil layers and allowing water flow, geotextiles reduce erosion, prevent clogging, and enhance subgrade strength.

4. What certifications and test reports are provided?

Comprehensive ASTM, ISO, and EN compliance documentation is supplied to ensure international project suitability.

Professional Consultation and Sample Requests

For engineers, contractors, and procurement professionals seeking reliable geotextile solutions, we offer a range of high-performance products tailored for separation, filtration, reinforcement, and drainage applications. Contact our technical team to request detailed specifications, competitive quotations, and material samples to ensure optimal selection for your project.

We are dedicated to delivering certified, high-quality geotextile fabrics that enhance infrastructure longevity, reduce maintenance costs, and support sustainable construction practices globally.