Aquaculture Fish Pond LDPE Geomembrane Sheet

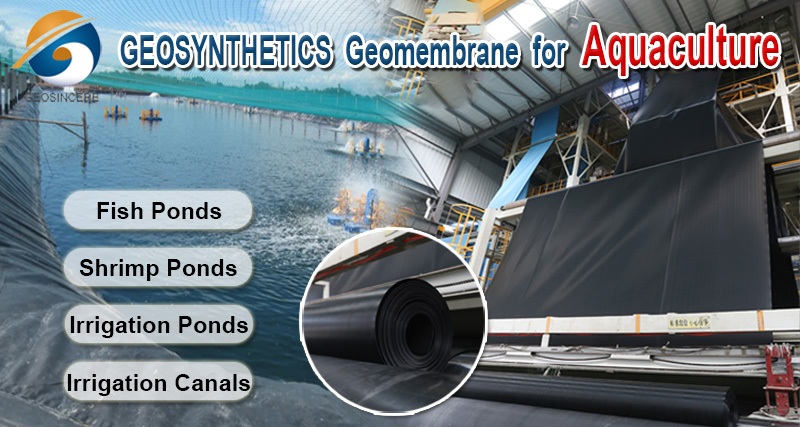

The rapid expansion of global aquaculture has increased the need for reliable pond lining materials capable of improving water retention and enhancing farming efficiency. The aquaculture fish pond LDPE geomembrane sheet is widely recognized as a stable, flexible and cost-effective lining solution for fish ponds, shrimp ponds and integrated aquaculture farming systems. As fish farming shifts toward higher-density operations, materials that provide consistent sealing and long-term durability have become essential for both small-scale operators and commercial aquaculture facilities.

Market data indicates that the global aquaculture infrastructure materials sector has grown steadily, supported by strong demand from Asia-Pacific regions such as China, Indonesia, Vietnam and India. These markets account for over 70% of the global aquaculture output, driving increasing orders for fish farming liner products and LDPE waterproof membrane systems. Rising environmental regulations and efficiency-driven farming models also contribute to greater adoption of engineered geomembrane sheets for pond sealing.

Global Market Background of Aquaculture Fish Pond LDPE Geomembrane Sheet

The rapid expansion of global aquaculture has increased the need for reliable pond lining materials capable of improving water retention and enhancing farming efficiency. The aquaculture fish pond LDPE geomembrane sheet is widely recognized as a stable, flexible and cost-effective lining solution for fish ponds, shrimp ponds and integrated aquaculture farming systems. As fish farming shifts toward higher-density operations, materials that provide consistent sealing and long-term durability have become essential for both small-scale operators and commercial aquaculture facilities.

Market data indicates that the global aquaculture infrastructure materials sector has grown steadily, supported by strong demand from Asia-Pacific regions such as China, Indonesia, Vietnam and India. These markets account for over 70% of the global aquaculture output, driving increasing orders for fish farming liner products and LDPE waterproof membrane systems. Rising environmental regulations and efficiency-driven farming models also contribute to greater adoption of engineered geomembrane sheets for pond sealing.

Industry Trends and Market Opportunities

Recent trends show that the adoption of aquaculture fish pond LDPE geomembrane sheet is accelerating due to several key factors. First, the industry is moving away from traditional clay ponds, which are prone to seepage, erosion and inconsistent water quality. LDPE sheets, with their controlled permeability and mechanical elasticity, offer a more stable foundation for controlled aquaculture environments.

Second, the rise of high-value species—such as shrimp, tilapia, catfish and ornamental fish—requires precise water management. Shrimp pond operations, in particular, rely heavily on geomembrane for shrimp pond facilities to maintain salinity, reduce disease exposure and support sustainable water cycles. Additionally, many international buyers prioritize pond lining systems capable of withstanding UV exposure in tropical climates, making LDPE a strong choice due to its balanced flexibility and weather resistance.

Technical Specifications of LDPE Geomembrane Sheet

The aquaculture fish pond LDPE geomembrane sheet is engineered for stability and optimized water containment. Standard specifications include:

• Thickness Range: 0.3mm – 1.5mm, depending on pond size and soil conditions

• Tensile Strength: 12–18 MPa, providing flexibility for uneven pond structures

• Elongation at Break: High elongation capacity to reduce stress cracking

• Permeability Rating: Extremely low permeability for long-term water retention

• UV Resistance: Suitable for long-term outdoor use in tropical climates

• Environmental Stability: Resistant to algae, acids, fertilizers and organic waste

These parameters ensure that the sheet delivers consistent performance across diverse farming environments, from inland freshwater ponds to coastal brackish-water aquaculture systems.

Material Composition and Product Structure

The LDPE geomembrane sheet is produced from low-density polyethylene resins combined with anti-aging additives, stabilizers and carbon black (for enhanced UV resistance). Its low-density molecular structure provides excellent elasticity, enabling the liner to adapt to subgrade irregularities and resist puncturing from rocks or sediment crusts. The sheet’s uniform thickness contributes to predictable sealing performance, which is essential for modern aquaculture pond lining system operations.

Manufacturing Process Flow

1. Raw Material Selection

High-quality LDPE granules are selected for uniformity, purity and controlled melt-flow properties.

2. Extrusion Film Production

The resin is processed through an advanced extrusion-blowing or flat-die casting system to ensure consistent sheet thickness.

3. Cooling and Stabilization

Rapid cooling technologies maintain dimensional stability and mechanical strength.

4. Surface Treatment and Inspection

Strength, elongation, thickness uniformity and sealing capacity are tested before packaging.

Application and Installation in Aquaculture

The aquaculture fish pond LDPE geomembrane sheet is primarily applied as the base sealing material for new pond construction or renovation. The installation process includes soil compaction, removal of sharp debris, placement of a protective geotextile layer (when needed), liner deployment and seam bonding. Proper installation ensures stable water levels, reduces the risk of contamination, and improves the efficiency of feed and water treatment systems.

In shrimp pond applications, LDPE liners reduce disease prevalence by eliminating mud surfaces where pathogens accumulate. For freshwater fish ponds, the sheet helps maintain consistent pH, reduces seepage loss and enhances the economic feasibility of high-density fish farming.

International Buyer Expectations and Procurement Pain Points

Global buyers typically prioritize material reliability, certification coverage and long-term performance. Customers from Southeast Asia and South Asia demand cost-effective sheets for large pond areas, while buyers from the Middle East and Africa emphasize UV resistance due to extreme solar exposure. European and North American buyers place greater value on traceability, production compliance and environmental testing.

Key procurement pain points include inconsistent thickness, uneven film quality, limited technical support and unclear installation guidance. Buyers also frequently request tailored solutions for aquaculture pond lining systems that include geotextile underlayers, geomembrane anchoring design and long-term service support.

Conclusion and Strategic Purchasing Recommendations

The aquaculture fish pond LDPE geomembrane sheet continues to gain market traction as fish and shrimp farming expand globally. With its adaptable structure, cost-efficiency and reliable waterproof performance, LDPE remains one of the most versatile materials in modern aquaculture engineering. Buyers seeking stable supply, dependable performance and verified quality standards should carefully examine material formulation, production technology and supporting installation services.

For detailed quotations, technical data reports and material samples, buyers are encouraged to request a full specification package tailored to their aquaculture project.

Frequently Asked Questions (FAQ)

1. What thickness is recommended for aquaculture pond construction?

Most fish and shrimp pond applications use 0.5mm–1.0mm LDPE sheets, depending on soil stability and pond size.

2. Can LDPE geomembrane sheets withstand long-term sunlight exposure?

Yes. LDPE liners with proper UV stabilizers are suitable for outdoor, high-temperature environments.

3. What advantages does LDPE offer over HDPE for aquaculture ponds?

LDPE provides higher elasticity and better adaptation to uneven ground, reducing stress cracking during pond settlement.

4. Do you provide technical support for pond installation?

We offer installation guidance, seam-welding recommendations and engineering advice based on project requirements.