LLDPE Pond Liner

Manufacturing Process

The manufacturing of LLDPE Pond Liner follows a controlled extrusion process to ensure uniform thickness and material consistency.

Virgin resin selection and material batching

Resin melting and homogenization using single or twin-screw extruders

Flat die or blown film extrusion forming continuous sheets

Thickness calibration and water or air cooling

Surface texturing through embossing rollers (if required)

Inline quality inspection (thickness, dispersion, tensile properties)

Rolling, cutting, labeling, and packaging

Critical equipment includes automated thickness scanners, carbon black dispersion analyzers, and tensile testing systems.

Product Definition of LLDPE Pond Liner

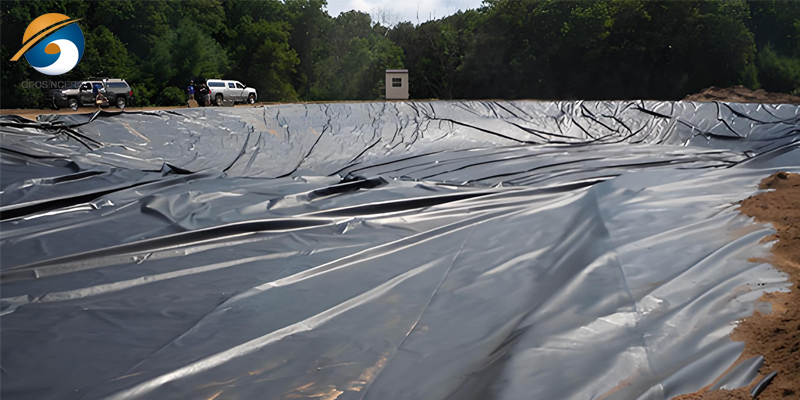

LLDPE Pond Liner is a flexible geomembrane manufactured from linear low-density polyethylene, engineered to provide reliable waterproof containment for ponds, reservoirs, and liquid storage systems. It combines high elongation, chemical stability, and installation adaptability for engineered water containment projects.

Technical Parameters and Specifications

LLDPE Pond Liner is designed to meet the performance requirements of civil, agricultural, and environmental engineering projects.

Material: Linear Low-Density Polyethylene (LLDPE)

Density: 0.915–0.935 g/cm³

Thickness Range: 0.5 mm – 2.5 mm

Standard Width: 4 m – 8 m

Standard Roll Length: 50 m – 200 m

Tensile Strength at Break: ≥ 12 MPa

Elongation at Break: ≥ 800%

Tear Resistance: ≥ 60 N

Hydrostatic Pressure Resistance: ≥ 0.25 MPa

Carbon Black Content: 2.0% – 3.0%

Service Temperature Range: -40°C to +60°C

Expected Service Life: ≥ 25 years (buried condition)

Structure and Material Composition

LLDPE Pond Liner features a homogeneous polymer structure optimized for flexibility and puncture resistance.

Base Polymer Layer: Linear low-density polyethylene resin providing elasticity and sealing performance

Carbon Black Additive: UV resistance and long-term outdoor durability

Antioxidant Package: Thermal stability and oxidation resistance

Smooth or Textured Surface: Optional texture for improved interface friction on slopes

Manufacturing Process

The manufacturing of LLDPE Pond Liner follows a controlled extrusion process to ensure uniform thickness and material consistency.

Virgin resin selection and material batching

Resin melting and homogenization using single or twin-screw extruders

Flat die or blown film extrusion forming continuous sheets

Thickness calibration and water or air cooling

Surface texturing through embossing rollers (if required)

Inline quality inspection (thickness, dispersion, tensile properties)

Rolling, cutting, labeling, and packaging

Critical equipment includes automated thickness scanners, carbon black dispersion analyzers, and tensile testing systems.

Industry Comparison with Alternative Pond Liner Materials

| Parameter | LLDPE Pond Liner | HDPE Liner | PVC Liner | EPDM Rubber |

|---|---|---|---|---|

| Flexibility | Excellent | Moderate | Good | Excellent |

| Puncture Resistance | High | High | Medium | Medium |

| Chemical Resistance | High | High | Medium | Medium |

| Installation Complexity | Moderate | Moderate | Low | Low |

| Service Life | 25+ years | 30+ years | 15–20 years | 20–25 years |

Application Scenarios

LLDPE Pond Liner is widely used by distributors, EPC contractors, and engineering firms in water containment projects.

Aquaculture ponds and fish farming facilities

Agricultural irrigation reservoirs

Landscape and decorative ponds

Stormwater retention and detention basins

Industrial water storage ponds

Wastewater treatment lagoons

Core Engineering Pain Points and Solutions

Subgrade Settlement: High elongation accommodates ground movement without cracking

Puncture Risk: Enhanced tear and puncture resistance protects against stones and roots

UV Exposure: Carbon black stabilization extends outdoor service life

Complex Geometry: Superior flexibility enables easy installation on irregular pond shapes

Risk Warnings and Mitigation Recommendations

Potential risks must be addressed through proper design and construction control.

Ensure subgrade is smooth, compacted, and free of sharp objects

Avoid excessive liner exposure before backfilling or water filling

Use certified welding equipment and trained technicians

Conduct seam integrity testing after installation

Procurement and Selection Guide

Define pond size, depth, and hydraulic load requirements

Select liner thickness based on puncture and pressure demands

Determine smooth or textured surface requirements

Confirm chemical compatibility with stored liquids

Verify compliance with ASTM or ISO standards

Assess roll dimensions for transport and installation efficiency

Request samples for material verification and testing

Engineering Case Application

In an aquaculture project covering approximately 60,000 m², a 1.0 mm LLDPE Pond Liner system was installed for fish farming ponds. The liner’s high flexibility allowed rapid installation over uneven subgrade, while hot wedge welded seams passed all air pressure tests, ensuring leak-free performance during commissioning.

Frequently Asked Questions (FAQ)

What thickness is common for pond liners? – Typically 0.75 mm to 1.5 mm

Is LLDPE suitable for aquaculture? – Yes, it is chemically inert and safe

How are seams welded? – Hot wedge or extrusion welding

Can LLDPE liners handle ground movement? – Yes, due to high elongation

Is UV resistance included? – Yes, with carbon black additives

What standards apply? – ASTM D6693, ASTM D5885

Can liners be repaired onsite? – Yes, using extrusion welding patches

Are custom roll sizes available? – Yes, depending on production capability

How long is the service life? – Over 25 years under proper conditions

Is third-party inspection recommended? – Recommended for large EPC projects

CTA – Request Commercial and Technical Support

Procurement managers and engineering teams may request pricing quotations, detailed technical datasheets, or project-specific LLDPE Pond Liner samples for evaluation and approval.

E-E-A-T Author Credentials

This content is prepared by geosynthetics engineering professionals with extensive experience in pond lining, water containment systems, and EPC project support. All technical data is based on established industry standards and verified engineering practices.