Aquaculture Custom HDPE Geomembrane Sheet

In recent years, the demand for Aquaculture Custom HDPE Geomembrane Sheet has surged as aquaculture continues to expand worldwide. With the increasing emphasis on sustainable fish farming and water resource protection, geomembrane sheets have become an essential material in pond construction, wastewater treatment, and irrigation systems.

According to global market reports, the geomembrane industry is expected to grow at a CAGR of over 6% between 2024 and 2030, driven by the rising aquaculture sector in Asia-Pacific, Africa, and Latin America. This growth reflects a shift from traditional pond liners to engineered HDPE materials that ensure longer service life, environmental compliance, and operational efficiency.

Global Overview of Aquaculture Custom HDPE Geomembrane Sheet

In recent years, the demand for Aquaculture Custom HDPE Geomembrane Sheet has surged as aquaculture continues to expand worldwide. With the increasing emphasis on sustainable fish farming and water resource protection, geomembrane sheets have become an essential material in pond construction, wastewater treatment, and irrigation systems.

According to global market reports, the geomembrane industry is expected to grow at a CAGR of over 6% between 2024 and 2030, driven by the rising aquaculture sector in Asia-Pacific, Africa, and Latin America. This growth reflects a shift from traditional pond liners to engineered HDPE materials that ensure longer service life, environmental compliance, and operational efficiency.

Market Trends and Industry Demand

The market for HDPE geomembrane for aquaculture is evolving rapidly as environmental regulations become stricter. Fish farmers and aquaculture project developers are prioritizing solutions that combine mechanical strength, UV resistance, and chemical stability.

Emerging economies such as Indonesia, India, and Vietnam are leading the adoption, where aquaculture contributes significantly to GDP. In these regions, the custom HDPE geomembrane sheet has become a critical investment to prevent seepage, reduce contamination, and maintain ideal water quality parameters.

Technical Specifications and Structural Design

The Aquaculture Custom HDPE Geomembrane Sheet is typically manufactured from high-density polyethylene resin, meeting ASTM and ISO standards. Common thickness ranges from 0.5mm to 2.0mm, depending on project requirements.

Key parameters include: - Tensile Strength: ≥27 MPa - Elongation at Break: ≥700% - Carbon Black Content: 2–3% - Puncture Resistance: ≥800 N

These properties ensure durability against physical stress, UV degradation, and microbial attack. The sheet structure consists of multiple layers—base resin, stabilizer, and anti-aging additive—enhancing both flexibility and chemical inertness.

Manufacturing Process and Quality Control

High-performance HDPE geomembrane sheets are produced through advanced blown film extrusion or flat die extrusion technology. During production, temperature, extrusion pressure, and cooling rates are precisely controlled to ensure uniform thickness and superior surface smoothness.

Every batch undergoes quality tests including tear resistance, permeability rate, and oxidation induction time (OIT). Continuous online inspection systems help maintain strict consistency, ensuring that each geomembrane sheet meets international aquaculture standards.

Applications in Modern Aquaculture

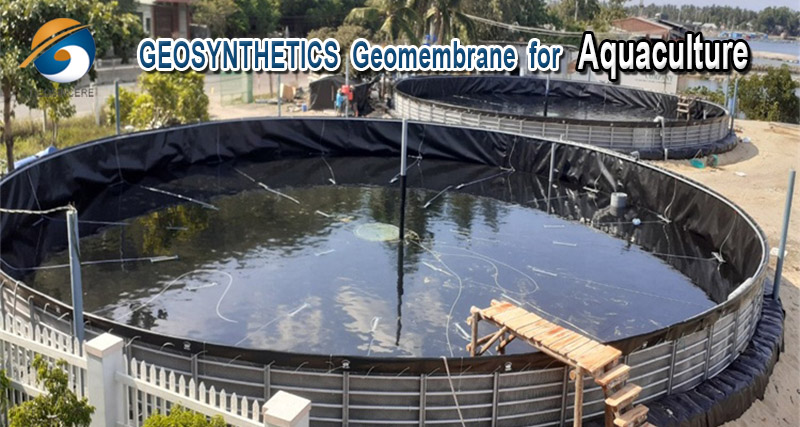

The HDPE geomembrane sheet for fish ponds plays a crucial role in various applications such as fish, shrimp, and crab farming. Its impermeable surface prevents leakage and maintains water levels, while its chemical stability resists fertilizers and disinfectants used in aquaculture systems.

Custom-fabricated sheets allow seamless installation even in irregular pond shapes, minimizing welding seams and reducing the risk of leakage. Many international buyers prefer prefabricated panels to simplify installation and shorten project timelines.

Buyer Preferences and Procurement Insights

International buyers prioritize three key factors when sourcing aquaculture geomembrane liners: quality certification, tensile strength, and delivery lead time. Buyers from Southeast Asia and the Middle East often request SGS or CE-certified materials with complete technical data sheets.

Price sensitivity remains high, but reliability and long-term durability are now greater priorities. Suppliers offering customized thickness, size, and installation guidance tend to gain stronger customer loyalty and repeat orders.

Future Outlook and Sustainability Trends

With growing environmental awareness, the HDPE geomembrane aquaculture market is shifting toward eco-friendly materials and improved recycling technologies. Manufacturers are exploring bio-based polyethylene blends and enhanced UV stabilization systems to extend lifespan under tropical conditions.

In the next five years, digital monitoring and smart pond management are expected to integrate with geomembrane-based infrastructure, providing real-time insights into water levels, temperature, and contamination control.

Frequently Asked Questions (FAQ)

1. What is the main advantage of using HDPE geomembrane in aquaculture?

It provides exceptional impermeability, UV resistance, and corrosion protection, preventing water loss and maintaining ideal conditions for aquatic life.

2. How long can a geomembrane sheet last in outdoor pond environments?

A high-quality sheet can last more than 10–15 years when properly installed and protected from direct mechanical damage.

3. What are the recommended thicknesses for aquaculture ponds?

Typically, 0.75mm to 1.5mm sheets are suitable for small and medium ponds, while 2.0mm is used for large or deep projects.

4. Can HDPE geomembrane be customized for irregular pond shapes?

Yes, custom fabrication and on-site welding ensure perfect fitting for any pond geometry or project layout.

Request Technical Support and Samples

We supply high-grade Aquaculture Custom HDPE Geomembrane Sheets tailored for various pond and reservoir projects. Our engineering team provides full technical documentation, installation guidance, and sample testing upon request.

Contact our specialists to obtain a quotation, download product specifications, or schedule a consultation for your next aquaculture infrastructure project.