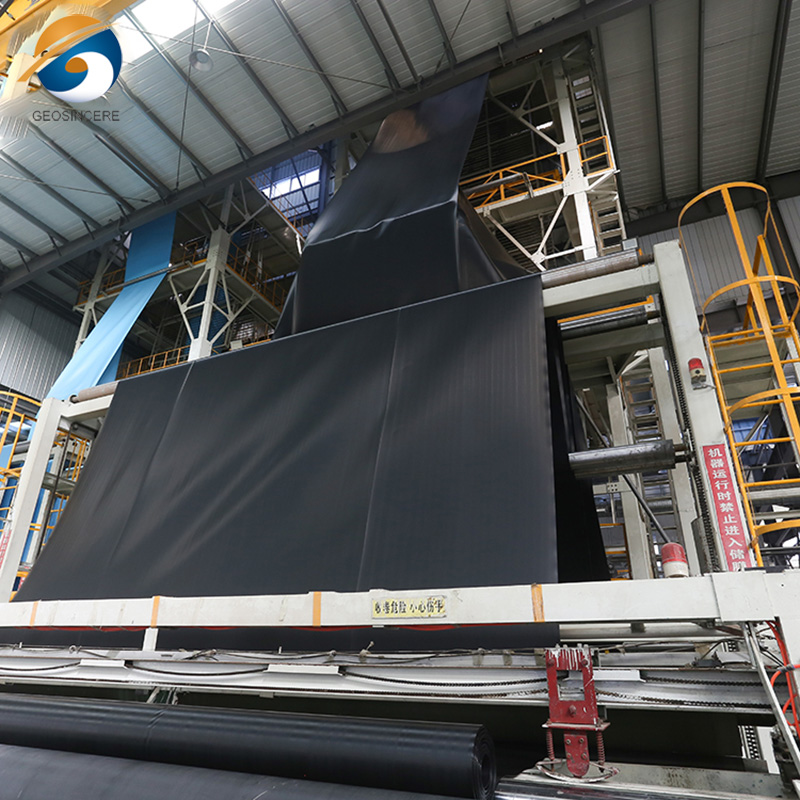

Preformed Plastic Pond Waterproof Membrane HDPE Dam Liner

Our Preformed Plastic Pond Waterproof Membrane HDPE Dam Liner is meticulously crafted to deliver exceptional waterproofing and containment capabilities for ponds and dams. This liner is constructed using high-density polyethylene (HDPE), a material renowned for its remarkable strength and ability to withstand punctures, tears, and UV degradation.

The primary objective of our HDPE dam liner is to ensure reliable waterproofing, guaranteeing that water remains contained within the designated area. By effectively preventing water leakage, this liner safeguards the integrity and longevity of ponds and dams, providing peace of mind to users.Our HDPE dam liner is environmentally friendly. It is crafted from a non-toxic material that poses no harm to aquatic life or the surrounding environment. The liner does not release harmful chemicals or leach into the water, ensuring the safety and well-being of the ecosystem.

When it comes to creating a durable and leak-proof water containment system, nothing beats the reliability and versatility of a preformed plastic pond waterproof membrane. Engineered from premium HDPE (High-Density Polyethylene), this advanced liner is designed for ponds, dams, aquaculture systems, and irrigation reservoirs that demand superior waterproofing, UV resistance, and long service life.

If you're planning a water project—whether residential, agricultural, or industrial—our preformed plastic pond waterproof membrane is the ideal choice to ensure lasting performance and peace of mind.

Why Choose a Preformed Plastic Pond Waterproof Membrane?

A high-quality preformed plastic pond waterproof membrane offers significant advantages over traditional concrete or clay linings:

✅ Effortless Installation

Unlike roll liners that require cutting, seaming, or welding, a preformed plastic pond waterproof membrane comes factory-molded to fit your design. This drastically reduces labor, time, and installation error.

✅ Leak-Proof Design

Manufactured in a seamless, single-body structure, the preformed plastic pond waterproof membrane eliminates the risk of leaks caused by joint failure or poor on-site welding.

✅ UV and Chemical Resistance

HDPE material is resistant to harmful UV rays, algae buildup, and harsh chemicals—making the preformed plastic pond waterproof membrane perfect for outdoor and exposed installations.

✅ Eco-Friendly and Safe

Food-grade HDPE ensures no contamination, making it safe for fish, plants, and irrigation systems. Plus, the preformed plastic pond waterproof membrane is recyclable, aligning with green building goals.

Technical Features of Our Preformed Plastic Pond Waterproof Membrane

| Feature | Specification |

|---|---|

| Material | High-Density Polyethylene (HDPE) |

| Thickness | 0.75mm to 2.0mm |

| UV Resistance | ≥ 95% retention after 2000 hrs |

| Flexibility | Excellent - adapts to irregular terrain |

| Tensile Strength | ≥ 28kN/m (ASTM D638) |

| Temperature Range | -60°C to +80°C |

| Lifespan | 20+ years in exposed environments |

Whether you're building a koi pond in your backyard or a 10,000 m² agricultural dam, our preformed plastic pond waterproof membrane is tailored for top-tier durability and performance.

Key Applications

The preformed plastic pond waterproof membrane is suitable for a wide range of water-related projects:

Ornamental Garden Ponds

Aquaculture & Fish Farming Tanks

Agricultural Irrigation Reservoirs

Rainwater Harvesting Systems

Industrial Wastewater Basins

Water Storage for Drought Resilience

Its flexibility and customizability allow you to choose from a wide range of sizes, shapes, and thicknesses—making the liner perfectly suited to both small home projects and large-scale installations.

Customization & Support

We understand that every project is unique. That’s why we offer:

Custom-molded preformed plastic pond waterproof membrane sizes

Color options (black, green, blue, etc.)

Technical drawings and 3D layout support

Installation guidance or on-site service

Bulk discounts for government, NGO, and commercial orders

With global delivery capabilities and years of field-proven reliability, we’re a partner you can trust for your water containment solutions.

Why Clients Worldwide Trust Our Preformed Plastic Pond Waterproof Membrane

✔ ISO 9001 & CE Certified

✔ Over 100,000 successful installations worldwide

✔ Direct factory supply = unbeatable value

✔ Fast lead times & reliable logistics

✔ 24/7 after-sales technical support

The preformed plastic pond waterproof membrane is more than a liner—it’s your guarantee of long-term water security, reduced maintenance, and sustainable water use.

Get a Free Quote Today!

Don't compromise on quality when it comes to your water containment project. Choose the preformed plastic pond waterproof membrane trusted by landscape designers, farmers, engineers, and contractors worldwide.

📞 Contact us now to get a custom quote, request a free sample, or speak with our engineers about your specific requirements.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||