A Deep Dive Into Landfill Liner Material

Underneath the large, often grassy hills of modern landfills, lies a sophisticated and vital engineering system whose only function is to keep things contained. The foremost and most important line of defense of this system is the material of the landfill liner. These materials are not just simple plastic sheets but are the pinnacle of geosynthetic engineering, crafted to separate the waste generated by society from the nature for decades, if not centuries. Their journey, make, and performance are the basics of securing water sources, safeguarding nature, and allowing the safe disposal of municipal solid waste - MSW (the abbreviation for the waste management sector) - in a world that produces more and more waste.

1. The Imperative for Landfill Liner Material

Before the era of the sanitary landfills, waste was thrown in open dumps, where the formation of the leachate—which is the most harmful liquid resulting from the infiltration of precipitation into the wastes—was inevitable. This leachate is in direct contact with the soil and the groundwater, hence the leachate travels along with heavy metals, organic compounds, and pathogens. The mid-20th-century environmental disasters woke the legislators up and brought about the era of strict rules and regulations, with the landmark law of the U.S. Resource Conservation and Recovery Act (RCRA) as the most striking example. These rules enforced the installation of composite liner systems in landfills of new construction, thus these facilities stopped being the crude waste receivers and became highly engineered containment sites. Landfill liner system play an essential role, and this role cannot be doubted: They are there to reduce the chances of unrestrained movements of leachate and landfill gases, which leads to the protection of human health and the environment.

2. Anatomy of a Modern Composite Landfill Liner Material

Rarely will one find a modern liner system in landfill made of a single material. It is a carefully planned, layered composite system whose each constituent plays a definite role. The major components, in the order from the bottom to the top, most probably will be:

2.1 Prepared Subgrade

The local soil is not only sufficiently compacted but also reshaped in order to provide a solid and even base.

2.2 Clay Layer (Bentonite or Compacted Clay)

The main water barrier. In many cases, a 1-2 foot layer of low-permeability compacted clay (permeability ≤ 1x10⁻⁷ cm/s) is employed. As another option, geosynthetic clay liners (GCLs) are utilized. GCL is composed of a layer of sodium bentonite clay that is placed between two geotextiles or glued to a geomembrane. When water is added, the bentonite expands, thereby forming an extremely efficient, self-sealing barrier.

2.3 Geomembrane

The highlight of the assembly. Landfill liner material is a pliable, man-made sheet of very low permeability. It works as the main, long-lasting barrier. HDPE geomembrane landfill liner is laid directly over the clay layer or GCL.

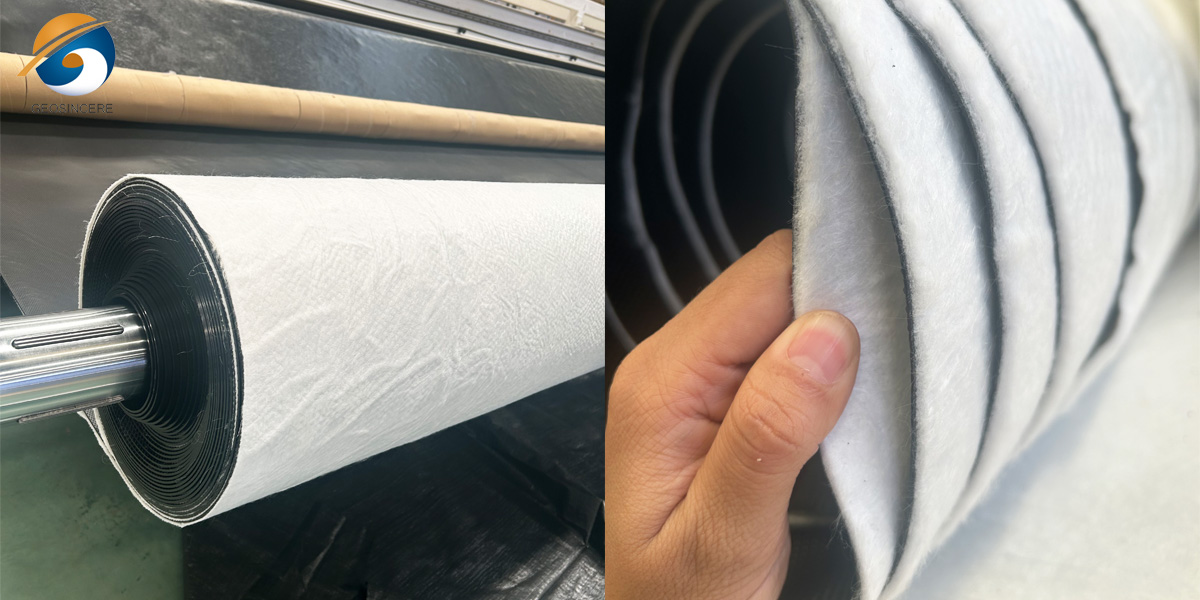

2.4 Geotextile Protection Layer

A strong, non woven geotextile is normally used covering the geomembrane for protection against puncture during the installation of the next layer.

2.5 Leachate Collection Layer

The layer above the landfill is of a sufficient thickness of granular gravel or a geonet (a grid-like plastic drainage core) is there. This layer is for the fast leachate collection and their road to the collection pipes–thus the hydraulic head (pressure) on the primary liner is lessened.

What really characterizes a composite liner is the interaction between the clay part and the geomembrane. The geomembrane for landfill is a very efficient barrier for diffusion and advection, whereas the clay layer beneath it is there as a redundant backup, can repair itself in the case of a tinyhole, and slows down any leak that might find its way through a crack in the geomembrane liner landfill.

3. Examining Materials for Key Landfill Liner Material

3.1 Geomembranes: The Main Barrier

The selection of a geo membranes polymer is a very important decision and mostly it depends on the material's resistance to chemicals, it long-lastingness and the ease of installation.

3.1.1 High-Density Polyethylene (HDPE)

A landfill liner that has been the great-work is probably HDPE. It is very famous for its almost perfect chemical resistance to various leachate components, good tensile strength, and very low permeability. The biggest problem of the hdpe geomembrane material is the arising of stress cracks if a condition is set and its limited flexibility in cold weather, thus making the process of welding seams a very important task for the skill of the operator.

3.1.2 Linear Low-Density Polyethylene (LLDPE)

Providing more than HDPE flexibility and elongation the product is more resistant to uneven settlement of the ground and also adaptable to the problematic subgrade. It has a good resistance to chemicals; however, in general, LLDPE geomembrane is less strong than HDPE against the attack of solvents.

3.1.3 Polyvinyl Chloride (PVC)

A flexible metal-sheet made of one piece and easy to weld, however, the migration of the plasticizer in the material (which, as a result, can make the plastic brittle) and lower resistance of the product to some of the organic materials have caused the decrease of the use of PVC in the first liners of MSW landfills. PVC geomembrane is still widely used in caps and other applications.

3.1.4 Flexible Polypropylene (fPP) and Reinforced Polyethylene

A polymer like fPP that is recently made is characterized by the combination of features such as flexibility and resistance to chemicals. In areas where materials are reinforced, the incorporation of the fabric scrim is for the tensile strength that is increased.

3.2 Geosynthetic Clay Liner (GCL): The Swelling Clay

Innovator GCL liner have completely changed the barrier component of the clay. Their benefits are very noticeable:

3.2.1 Speedy Installation

In rolls of large sizes, they come and are unrolled like a carpet, thus they cover a big area much faster than the transporting, the spreading, and the compacting of 2feet of native clay.

3.2.2 Purity

Being made under controlled conditions, they offer a uniform thickness and hydraulic performance.

3.2.3 Superior Hydraulic Performance

The sodium bentonite that is hydrated is able to achieve permeabilities down to 1x10⁻⁹ to 1x10⁻¹⁰ cm/s which is a few times lower than the permeabilities of the compacted clay layers.

3.2.4 Self-Sealing Feature

The bentonite is able to expand and from that small punctures in the overlying geomembrane it can seal it. However, geosynthetic liner have certain drawbacks, such as long-term performance in certain chemical environments (for example, with high ionic strength leachate) and being prone to ion exchange, thus their swelling capacity can be reduction.

3.3 Compacted Clay Liner (CCL): The Traditional

Mineral Barrier When CCLs are made properly from good local soils, they are capable of providing a strong, safe, and time-proven barrier. Their effectiveness depends much on the quality of the construction which in turn should be controlled strictly (among other things, moisture content, compaction effort, lift thickness) so that there would be no cracks, voids, and increase of permeability. The main advantage of them is predictable mineralogical behavior and high adsorption capacity for contaminants.

4. Landfill Liner Material - Performance, Challenges, and the Future

The main challenge for a landfill liner material is time. Landfills

are made with a post-closure care period (30-50 years), whereas the waste remains dangerous for a lot more years. Major long-term challenges are:

4.1 Long-Term Degradation

Polymers may face oxidative degradation, stress cracking, and loss of plasticizer. Additives such as carbon black (that makes HDPE uv-resistant) and antioxidants are very important for the lifespan of the materials.

4.2 Chemical Compatibility

Leachate chemistry changes over decades. Liner in landfill materials should be able to resist attacks by acids, swelling by solvents, and oxidation.

4.3 Physical Stresses

Subsidence, seismic activity, and root penetration (for caps) are some of the physical stresses that the liner system has to face.

The future landfill liner materials are expected to have enhanced durability features and be "smart" functional. Some of the research areas include:

- Novel Polymers and Nanocomposites: The addition of nano-clays or other particles can improve the barrier properties, mechanical strength, and chemical resistance of the material.

- Durability Monitoring: The installation of sensor networks can help track changes in temperature, strain, and even leakage in real-time thus, enabling preventive maintenance.

- Biochemical Barriers: One of the ideas is that certain layers can support microbial activity that will biologically degrade the contaminants before they migrate.

Conclusion

Landfill liner materials are, essentially, the silent heroes that protect our underground environment. From widely used HDPE geomembrane to the latest GCL, these carefully designed materials are the embodiment of the "concentrate and contain" concept which is at the core of the modern waste management system. Choosing, designing, and installing these materials call for an in-depth knowledge of geotechnical engineering, polymer science, and hydrogeology.

With the worldwide waste trend upward and human tolerance to environmental risk on the decline, the perseverance in innovating and carefully applying these materials will, undoubtedly, be the main pillars of the sustainable waste infrastructures going forward. They are not simply plastic sheets or clay layers; rather, they represent a crucial social contract with the future, thus, ensuring that today's waste will not be the source of the environmental crisis of tomorrow.

Picking a Dependable GEOSINCERE Geosynthetics Supplier to Get a Price Quotation for You :

GEOSINCERE Geosynthetics has been continually working on technological innovation, upgrading of manufacturing facilities and engineering turnkey project capabilities. We have put $10 million into our manufacturing plant which is outfitted with advanced fully automated production lines to produce high-quality HDPE geomembranes and other geosynthetics with efficient processes.

Our wide variety of geosynthetics products are very popular with their guaranteed quality, high performance, great durability, and the best cost-effectiveness.

The Shandong Geosino New Material Co., Ltd.(GEOSINCERE Geosynthetics)of HDPE geomembranes along with other geosynthetics products and solutions can be your ideal partner by our reliable technologies, innovative engineering solutions, and outstanding customer services. GEOSINCERE Geosynthetics consistently endeavors to address the most complicated civil, mining, and environmental issues through our innovative, high-performing geosynthetic products.

We are competitive because of quality assurance, factory price, and quick delivery time.