HDPE Geomembrane: Ultimate Guide to Landfill Liners and Industrial Applications

In an era defined by increasing environmental consciousness and stringent regulatory frameworks, the management of waste and containment of hazardous materials has become a paramount global concern. At the heart of modern environmental protection infrastructure lies a critical component: the High Density Polyethylene geomembrane, most commonly deployed as a landfill liner. This engineered material represents a pinnacle of geosynthetic innovation, providing a robust, impermeable barrier that safeguards soil and groundwater from contamination. This article delves into the fundamental properties, manufacturing process, and extensive applications of HDPE landfill liner, underscoring their indispensable role in environmental engineering.

1. Understanding HDPE Geomembrane Landfill Liner : The Material Science Behind the Barrier

High Density Polyethylene is a petroleum-based polymer characterized by its high strength-to-density ratio. Its molecular structure, with minimal branching, allows the polymer chains to pack closely together, resulting in a material that is exceptionally durable, chemically resistant, and impermeable.

The transformation of raw HDPE resin into a geomembrane liner is a sophisticated manufacturing process, typically involving flat-die extrusion. The process begins with the selection of primary resin, often blended with specialized additives including:

1.1 Carbon Black: Added at 2-3% concentration, it provides critical protection against ultraviolet (UV) radiation degradation, significantly enhancing the material's long-term durability when exposed to sunlight during installation. It also improves thermal absorption and some mechanical properties.

1.2 Antioxidants: These additives retard the oxidative degradation of the polymer, which can be initiated by heat, mechanical stress, and exposure to certain chemicals, thereby extending the service life of the

1.3 Stabilizers: They help maintain the polymer's integrity during the high-temperature extrusion process and throughout its service life.

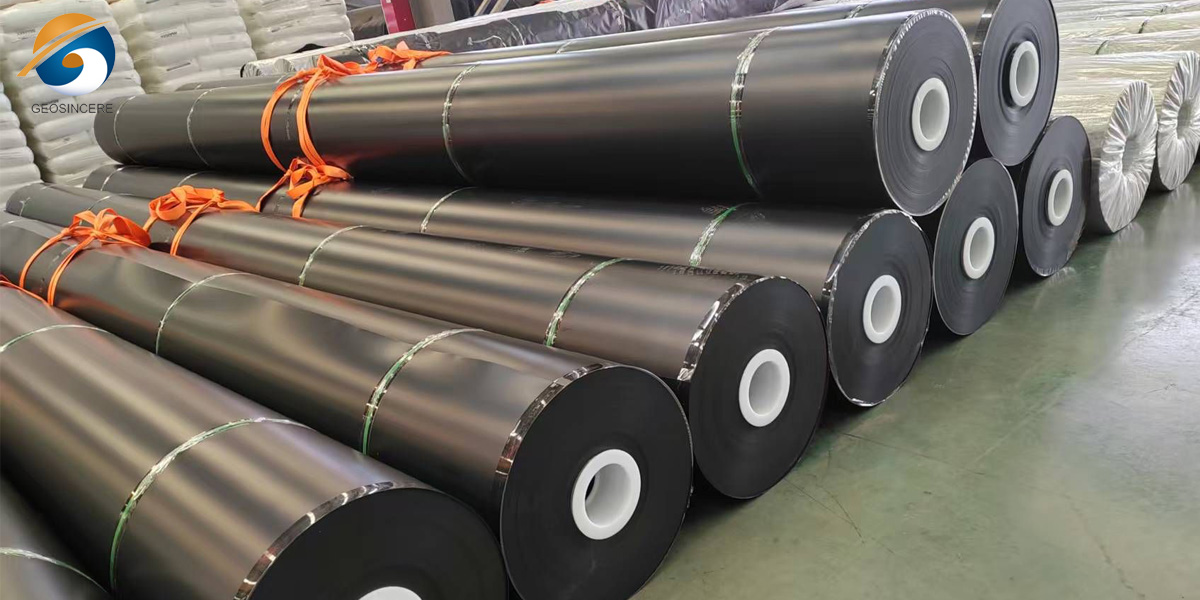

The resin and additive mixture is melted and forced through a flat die, creating a continuous sheet of molten polymer. This sheet is then precisely calibrated to a specific thickness using rollers before being cooled and wound into large rolls for shipment to project sites. These geomembrane rolls can be manufactured to be exceptionally wide (up to 9 meters or more), which minimizes the number of field seams required—a critical factor for ensuring overall system integrity.

2. Key Properties That Make HDPE Geomembrane Landfill Liner the Premier Choice

The widespread adoption of hdpe landfill liner is attributable to a unique combination of physical and chemical properties:

2.1 Exceptional Impermeability: Geomembrane liner landfill has an extremely low hydraulic conductivity, effectively creating a barrier that prevents the passage of liquids and vapors. This is quantified by its permeability coefficient, which is exceptionally low, making it ideal for containing leachate—the toxic liquid that percolates through waste.

2.2 Outstanding Chemical Resistance: Geomembrane for landfill is highly resistant to a wide spectrum of chemicals, including strong acids, bases, and salts. This is crucial in landfill environments where leachate can be highly corrosive and in industrial applications containing aggressive fluids.

2.3 High Durability and Tensile Strength: HDPE geomembranes exhibit high tensile strength, elongation, and tear resistance. This allows them to withstand significant stresses, including settlement of the underlying subgrade and the overburden pressure of the waste mass above.

2.4 Puncture and Tear Resistance: While no material is entirely immune, the inherent toughness of geomembrane liner landfill provides excellent resistance to punctures from sharp objects in the subgrade or waste.

2.5 Long Service Life: When formulated correctly with carbon black and antioxidants, landfill liner system is designed for long-term performance. Industry standards and testing predict a service life exceeding hundreds of years when properly installed and protected.

2.6 Cost-Effectiveness: Compared to traditional containment methods like compacted clay, HDPE liner offers a superior barrier at a competitive installed cost, especially when considering its longevity and performance reliability.

3. HDPE Geomembrane Landfill Liner Primary Application: The Modern Sanitary Landfill

The most prominent and critical application of HDPE liners is in the construction of sanitary landfills. A modern landfill is not merely a "dump"; it is a highly engineered containment system designed to isolate waste from the surrounding environment. A composite liner system, which is the global standard, typically consists of the following layers where landfill plastic liner plays a starring role:

3.1 HDPE Geomembrane Landfill Liner for Primary HDPE Liner

This is the first and most critical barrier. A 1.5mm to 2.0mm thick HDPE geomembrane is installed on a prepared, smooth subgrade.

3.2 HDPE Geomembrane Landfill Liner for Leachate Collection Layer

Placed directly above the primary liner, this layer consists of a network of perforated pipes and gravel. It is designed to quickly collect and remove leachate, preventing its buildup and reducing hydraulic head on the liner system.

3.3 HDPE Geomembrane Landfill Liner for Secondary (or Redundant) Liner System:

In double-lined landfills, a second HDPE geomembrane is installed beneath the primary liner, often with a leak detection system between the two. This provides a critical failsafe, ensuring that any leak in the primary liner is detected and contained before it can reach the natural environment.

3.4 HDPE Geomembrane Landfill Liner for Final Cap or Cover

At the end of a landfill cell's life, it is sealed with a final cover system. This cap, which also features an HDPE geomembrane, acts as a "raincoat," minimizing water infiltration into the closed waste mass, thereby reducing future leachate generation and controlling gas migration.

4. Beyond Landfill : Diverse Applications of HDPE Geomembrane

The utility of HDPE geomembranes extends far beyond municipal solid waste landfills. Their robust properties make them suitable for a vast array of containment applications:

4.1 HDPE Geomembrane for Mining and Heap Leach Pads

In the mining industry, hdpe membrane is used to line heap leach pads, where chemical solutions are applied to ore piles to extract precious metals. They contain these highly acidic or cyanide-laden solutions, preventing environmental contamination. They are also used for tailings impoundments.

4.2 HDPE Geomembrane for Water and Liquid Storage Reservoirs

Plastic liner landfill is widely used to line potable water reservoirs, irrigation ponds, and firewater storage tanks to prevent seepage losses and maintain water quality. It is also used in decorative lagoons and aquaculture ponds.

4.3 HDPE Geomembrane for Wastewater and Treatment Lagoons

Municipal and industrial wastewater treatment facilities use HDPE geomembrane liner to contain treatment basins, anaerobic digesters, and settling ponds, ensuring that untreated effluent does not seep into groundwater.

4.4 HDPE Geomembrane for Energy and Industrial Applications

HDPE liner form secondary containment barriers around fuel storage tanks, under chemical processing plants, and in solar evaporation ponds, providing a critical layer of protection against accidental spills.

4.5 HDPE Geomembrane for Transportation Infrastructure

In a more recent application, hdpe geomembrane sheet is used as a waterproofing layer in tunnels and beneath roadways to protect structures from water damage.

5. HDPE Geomembrane Landfill Liner Installation and Critical Considerations: The Importance of Expertise

The performance of an HDPE liner is entirely dependent on two factors: the quality of the manufactured material and, just as importantly, the quality of its installation. Proper installation involves:

5.1 Subgrade Preparation: The soil foundation must be smooth, compacted, and free of sharp rocks, roots, or debris that could puncture the liner.

5.2 Panel Deployment and Seaming: Unrolling the panels must be done carefully. The most critical task is creating strong, continuous, and impermeable seams. This is primarily achieved through thermal fusion:

- Dual Hot Wedge Welding: A hot wedge is passed between two overlapping sheets, melting the surfaces. Immediately after, pressure rollers fuse the molten HDPE together, creating two parallel weld seams with an air channel between for non-destructive testing.

- Extrusion Welding: A ribbon of molten HDPE polymer is extruded over the edge of a seam or into a patch, fusing the underlying materials. This is often used for detail work, patches, and repairs.

5.3 Quality Assurance/Quality Control (QA/QC): Every linear inch of seam must be tested. This includes non-destructive testing (NDT) like air pressure testing of the dual-weld channel and destructive testing (DT) where sample seams are cut from the field and tested in a lab for shear and peel strength.

6. Conclusion

The HDPE landfill liner is more than just a sheet of plastic; it is a sophisticated, engineered solution that forms the foundation of modern environmental protection. Its unparalleled combination of impermeability, chemical resistance, and durability makes it the material of choice for containing some of the world's most challenging waste streams and liquids. From securing the base of a municipal landfill to lining a potable water reservoir, HDPE geomembranes provide the reliable barrier necessary to protect precious soil and groundwater resources for generations to come. As technology and material science advance, HDPE continues to evolve, solidifying its status as an indispensable tool in the global effort to build a more sustainable and safer world.

For expert consultation, high-quality HDPE/LDPE/LLDPE geomembranes, and comprehensive geosynthetic solutions, please do not hesitate to contact us. Shandong geosino new material co.,ltd (GEOSINCERE Geosynthetics) team of engineers is ready to support your project anywhere in the world.