Landfill Liner Material

Manufacturing Process

Polymer extrusion: HDPE/LLDPE resin melted and extruded through flat die.

Calendering: Film thickness controlled within ±0.05 mm tolerance.

Texturing (optional): Single or double-sided friction enhancement.

Cooling & trimming: Dimensional control for roll width 7–8 m.

Roll winding: Uniform tension to avoid creases during installation.

Factory testing: Tensile strength, OIT, carbon black dispersion per GM13.

Engineering note: Weldability and oxidation resistance are the two highest-priority QC items for landfill liner material.

Concise Definition

Landfill liner material refers to engineered geomembranes and geosynthetic components used to prevent leachate migration in municipal solid waste and industrial waste landfills. Designed for long-term chemical resistance and hydraulic containment, it ensures environmental safety for EPC contractors, landfill operators, and regulatory-compliant infrastructure projects.

Technical Parameters & Specifications

| Parameter | Typical Specification |

|---|---|

| Material Type | HDPE, LLDPE, GCL composite, geotextile-backed liners |

| Thickness Range | 1.0–2.5 mm (geomembrane) |

| Tensile Strength | ≥ 25 kN/m |

| Puncture Resistance | ≥ 600 N |

| Chemical Resistance | Compatible with MSW leachate, acids, alkalis |

| Permeability Coefficient | ≤ 1.0 × 10⁻¹⁴ m/s (1.5–2.0 mm HDPE) |

| Carbon Black Content | 2–3% for UV protection |

| Service Life | ≥ 50 years under landfill conditions |

| Standard Compliance | GM13, ISO 13491, ASTM D6693 |

Structure & Material Composition

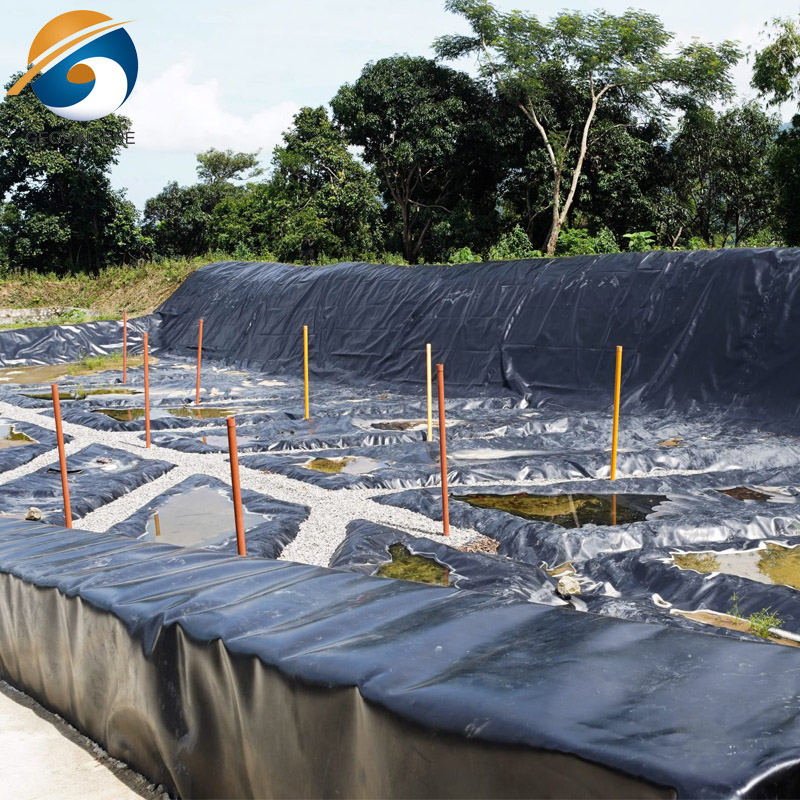

Primary Geomembrane Layer: HDPE or LLDPE smooth/textured sheet for containment.

Bentonite Layer (GCL): Sodium bentonite providing self-sealing hydraulic performance.

Geotextile Backing: Needle-punched nonwoven stabilization and mechanical protection.

Drainage Geocomposite: HDPE core grid + geotextile filtration layer for leachate removal.

Protective Soil Layer: Typically 300–500 mm compacted soil overlay.

Manufacturing Process

Polymer extrusion: HDPE/LLDPE resin melted and extruded through flat die.

Calendering: Film thickness controlled within ±0.05 mm tolerance.

Texturing (optional): Single or double-sided friction enhancement.

Cooling & trimming: Dimensional control for roll width 7–8 m.

Roll winding: Uniform tension to avoid creases during installation.

Factory testing: Tensile strength, OIT, carbon black dispersion per GM13.

Engineering note: Weldability and oxidation resistance are the two highest-priority QC items for landfill liner material.

Industry Comparison

| Material | Permeability | Chemical Resistance | Cost | Service Life |

|---|---|---|---|---|

| HDPE Geomembrane | Very Low | Excellent | Medium | 50+ years |

| LLDPE Geomembrane | Very Low | Excellent | Medium | 40+ years |

| GCL (Bentonite) | Low | Medium | Medium–High | 30+ years |

| Compacted Clay Liner | Moderate | Medium | High (labor) | Variable |

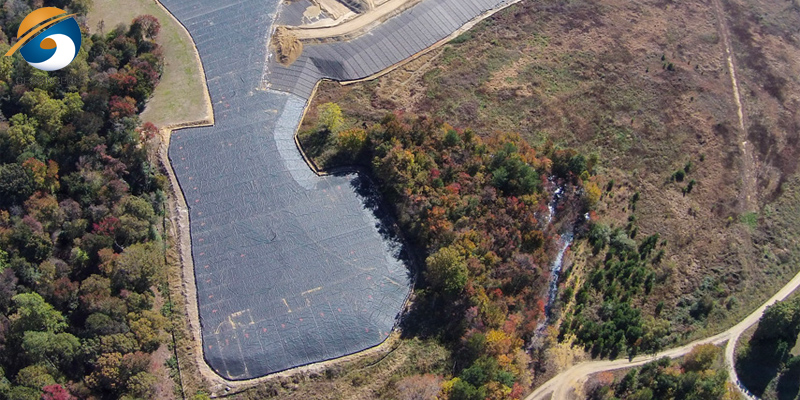

Application Scenarios

Municipal solid waste landfills (cell base liner + capping)

Industrial waste containment sites

Hazardous waste stabilization facilities

Mining tailing ponds and heap leach pads

Wastewater evaporation ponds and retention basins

Engineered landfill expansion layers for EPC contracts

Core Pain Points & Engineering Solutions

Leachate migration risk: Multi-layer geomembrane system with permeability ≤ 1.0 × 10⁻¹⁴ m/s.

UV degradation during installation: Carbon black and antioxidant OIT reinforcement.

Welding failures at joints: Double-track hot wedge welding + onsite shear/peel tests.

Differential settlement: Flexible LLDPE or textured HDPE for increased elongation (>700%).

Risk Warnings & Mitigation Advice

Do not install under wind speeds > 25 km/h to avoid membrane lift.

Avoid dragging rolls on gravel or sharp aggregate surfaces.

Conduct mandatory spark testing or vacuum box testing on all seams.

Confirm chemical compatibility for industrial landfill leachates.

Procurement & Selection Guide (≥6 Steps)

Define landfill category (MSW, industrial, hazardous) and regulatory standards.

Select membrane thickness based on cell depth and mechanical load.

Request GM13 or equivalent QC certificate for every batch.

Check OIT aging test results for long-term stability.

Evaluate weldability by inspecting resin formulation and carbon black dispersion.

Request onsite technical support for welding, testing, and QA documentation.

Engineering Case Reference

A 210,000 m² municipal landfill expansion project used a composite 2.0 mm HDPE membrane + GCL system. On-site welding passed all destructive tests (ASTM D6392), and leakage detection over 6 months indicated zero measurable infiltration. EPC contractor reported 18% reduction in installation time due to optimized roll width and seam layout.

FAQ

What thickness is recommended? — 1.5–2.0 mm HDPE for MSW landfill bases.

Is textured geomembrane necessary? — Yes, for slopes > 1:3.

Can GCL replace compacted clay? — Yes, when soil availability is limited.

How long does landfill liner material last? — Over 50 years in controlled conditions.

Is HDPE safe for hazardous waste? — Yes, when compliant with GM13 standards.

What welding method is preferred? — Hot wedge double-track welding.

What is the typical roll width? — 7–8 m for efficient installation.

Does temperature affect welding? — Yes, ideal range is 260–320°C.

Can liners be used with leachate collection systems? — Yes, paired with drainage geocomposites.

Do geomembranes require protective soil? — Typically 300–500 mm to prevent damage.

Request Quotation / Technical Documents / Engineering Samples

For landfill liner material pricing, engineering drawings, regulatory compliance documents, and field welding guidance, contact our technical sales team for project-based support.

E-E-A-T Author Credential Statement

Article prepared by an environmental engineering technical writer with over 10 years of experience in geomembrane QC audits, landfill design review, and procurement consulting for EPC contractors and waste management authorities.

Company Profile