What is Geo Clay Liner Used for?

Product Definition: What Is a Geo Clay Liner?

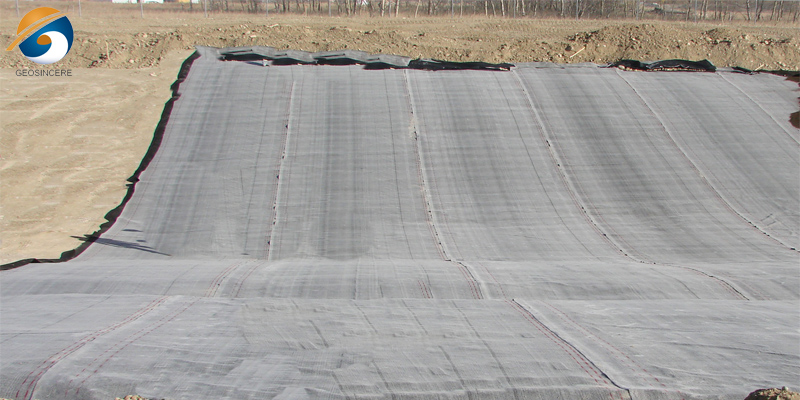

A Geo Clay Liner (GCL) is a factory-manufactured hydraulic barrier consisting of a layer of sodium bentonite clay encapsulated between geotextiles or bonded to a geomembrane. It is designed to provide extremely low permeability for containment and environmental protection applications.

What Is Geo Clay Liner Used for in Civil and Environmental Engineering?

Understanding what is geo clay liner used for is critical for EPC contractors and procurement managers involved in containment, waste management, and water protection projects. GCLs are primarily used as impermeable liners to control fluid migration and protect soil and groundwater systems.

Technical Parameters and Specifications

Geo Clay Liner performance is defined by standardized physical and hydraulic parameters suitable for large-scale infrastructure projects.

Bentonite Type: Sodium bentonite

Bentonite Mass: 3.5–5.5 kg/m²

Hydraulic Conductivity: ≤ 5 × 10⁻¹¹ m/s

Peel Strength: ≥ 600 N/m

Shear Strength (Internal): ≥ 25 kPa

Geotextile Type: Woven / Nonwoven PP or PET

Standard Roll Width: 4–5 m

Standard Roll Length: 30–50 m

Design Service Life: ≥ 50 years (buried conditions)

Applicable Standards: ASTM D5887, ASTM D5890, ISO 10772

Structure and Material Composition

The structural composition explains what is geo clay liner used for in high-risk containment environments.

Top Geotextile Layer: Woven or nonwoven fabric providing tensile strength and protection

Sodium Bentonite Core: Expansive clay forming a self-sealing impermeable layer

Bottom Geotextile Layer: Ensures confinement and shear resistance

Needle-Punching or Adhesive Bonding: Maintains integrity during installation

Optional Geomembrane Lamination: Enhances chemical resistance and barrier performance

Manufacturing Process

Geo Clay Liner manufacturing follows controlled industrial procedures to ensure uniform hydraulic performance.

Selection and testing of sodium bentonite raw material

Geotextile fabric production or sourcing

Uniform bentonite granule distribution across geotextile

Needle-punching or thermal bonding of layers

Moisture content control and inline quality inspection

Roll cutting, labeling, and packaging

Key equipment includes bentonite spreaders, needle-punching machines, moisture analyzers, and tensile testing systems.

Industry Comparison: GCL vs Other Liner Systems

| Parameter | Geo Clay Liner | HDPE Geomembrane | Compacted Clay Liner | Composite Liner |

|---|---|---|---|---|

| Hydraulic Conductivity | Very Low | Extremely Low | Low | Extremely Low |

| Installation Speed | Fast | Moderate | Slow | Moderate |

| Thickness | 5–10 mm | 1–3 mm | 500–1000 mm | 6–15 mm |

| Self-Healing Ability | Yes | No | Limited | Partial |

| Cost Efficiency | High | Moderate | Low | Moderate |

Application Scenarios

From a practical engineering perspective, what is geo clay liner used for spans multiple containment-driven sectors.

Municipal solid waste landfills

Hazardous waste containment facilities

Mining tailings ponds and heap leach pads

Water reservoirs and canals

Secondary containment for industrial sites

Artificial lakes and decorative ponds

Core Engineering Pain Points and Solutions

Groundwater Contamination Risk: GCL provides ultra-low permeability barriers

Limited Construction Space: Thin profile replaces thick compacted clay layers

Subgrade Irregularities: Bentonite self-seals minor defects

Construction Time Constraints: Roll-based installation accelerates project schedules

Risk Warnings and Mitigation Recommendations

While understanding what is geo clay liner used for, potential risks must be considered.

Premature hydration before confinement should be avoided

Exposure to saline or calcium-rich water may reduce swelling capacity

Proper overlap and sealing are critical to performance

Cover layers should be placed promptly after installation

Procurement and Selection Guide

Define project containment requirements and regulatory standards

Evaluate chemical compatibility of bentonite with site liquids

Select appropriate GCL type (stitched, needle-punched, laminated)

Verify bentonite mass and hydraulic conductivity values

Request third-party laboratory test reports

Assess supplier manufacturing capacity and QA procedures

Confirm logistics, roll dimensions, and onsite support

Engineering Case Study

In a municipal landfill expansion project, a needle-punched Geo Clay Liner with bentonite mass of 5.0 kg/m² was installed beneath a composite liner system. Field permeability testing confirmed hydraulic conductivity below 1 × 10⁻¹¹ m/s, meeting environmental compliance requirements while reducing installation time by over 30% compared to compacted clay liners.

Frequently Asked Questions (FAQ)

What is geo clay liner used for? – Environmental containment and seepage control

Is GCL suitable for landfills? – Yes, widely used globally

Can GCL replace compacted clay liners? – In many projects, yes

Does GCL self-heal? – Yes, due to bentonite swelling

Is GCL chemically resistant? – Moderate, compatibility testing required

How long does GCL last underground? – Over 50 years

Can GCL be combined with geomembranes? – Yes, as composite liners

Does GCL require welding? – No, overlaps are used

Is installation equipment complex? – No, standard lifting tools suffice

Is third-party testing recommended? – Strongly recommended

CTA – Request Quotation or Technical Documentation

Procurement teams, EPC contractors, and distributors may request detailed technical datasheets, compliance documentation, pricing information, or engineering samples to support tendering and project design validation.

E-E-A-T Author Credentials

This content is prepared by engineering specialists with extensive experience in geosynthetics design, landfill engineering, and environmental containment systems. All technical parameters are aligned with internationally recognized standards and field-proven engineering practices.