High Density Polyethylene HDPE Geomembrana

High Density Polyethylene (HDPE) Geomembrana is a robust and adaptable synthetic liner utilized across a wide range of industries to create an impervious barrier against liquids, gases, and solids. This highly versatile material finds extensive applications in civil engineering, environmental protection, mining, agriculture, and various other sectors.The exceptional durability, flexibility, and weldability of HDPE geomembrana make it a preferred choice in various industries.Its resistance to punctures, tears, and abrasion ensures long-term protection and performance in challenging environments.

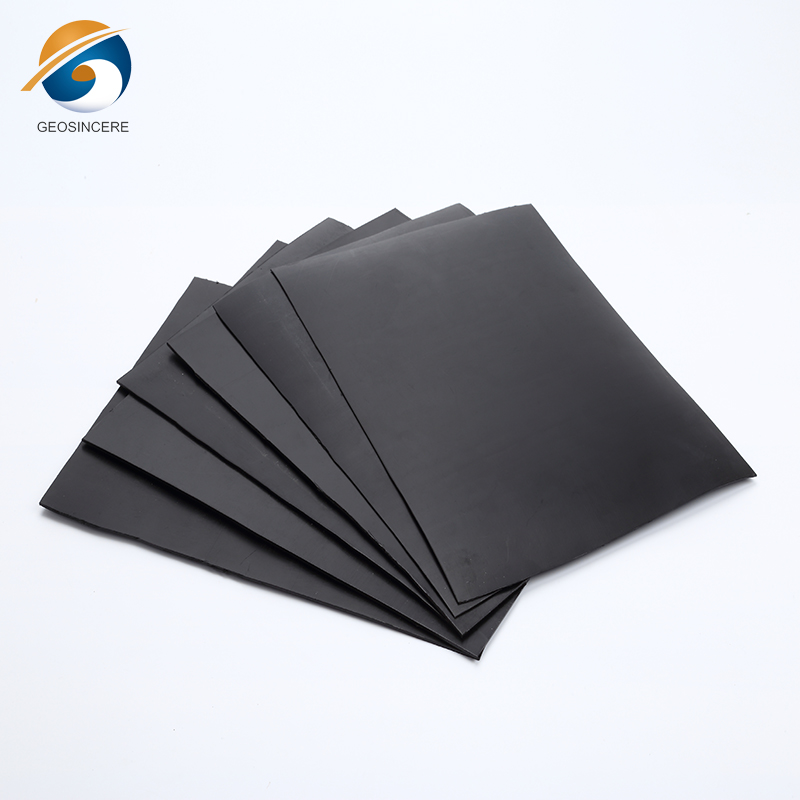

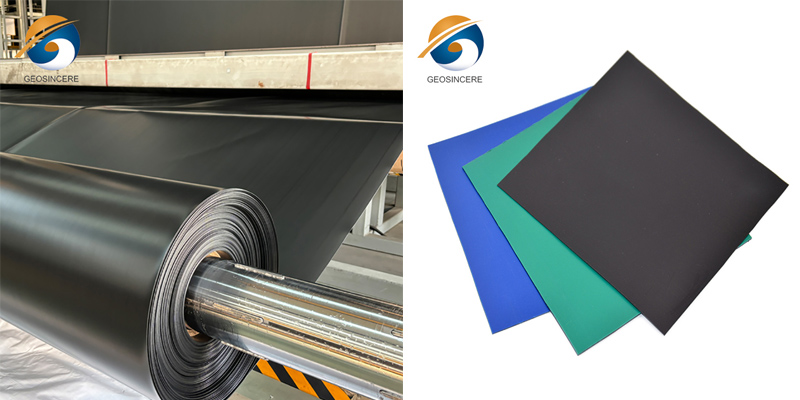

HDPE geomembrana is typically available in various color, thicknesses, roll widths, and lengths, allowing customization based on specific project requirements.

When it comes to industrial-scale waterproofing and containment, no solution outperforms High Density Polyethylene HDPE Geomembrana. Engineered with precision, HDPE geomembrana is the gold standard in geosynthetic liners, offering unmatched chemical resistance, high mechanical strength, and long-term durability across a wide range of environmental and industrial applications.

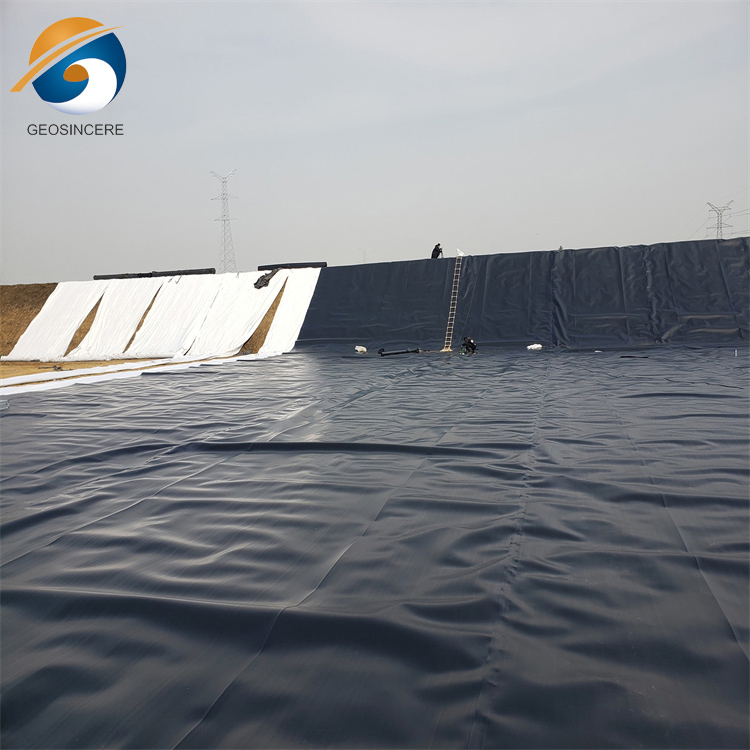

Whether you are managing a landfill, lining a reservoir, or building a mining containment system, High Density Polyethylene HDPE Geomembrana provides the impermeable protection you can rely on.

What is High Density Polyethylene HDPE Geomembrana?

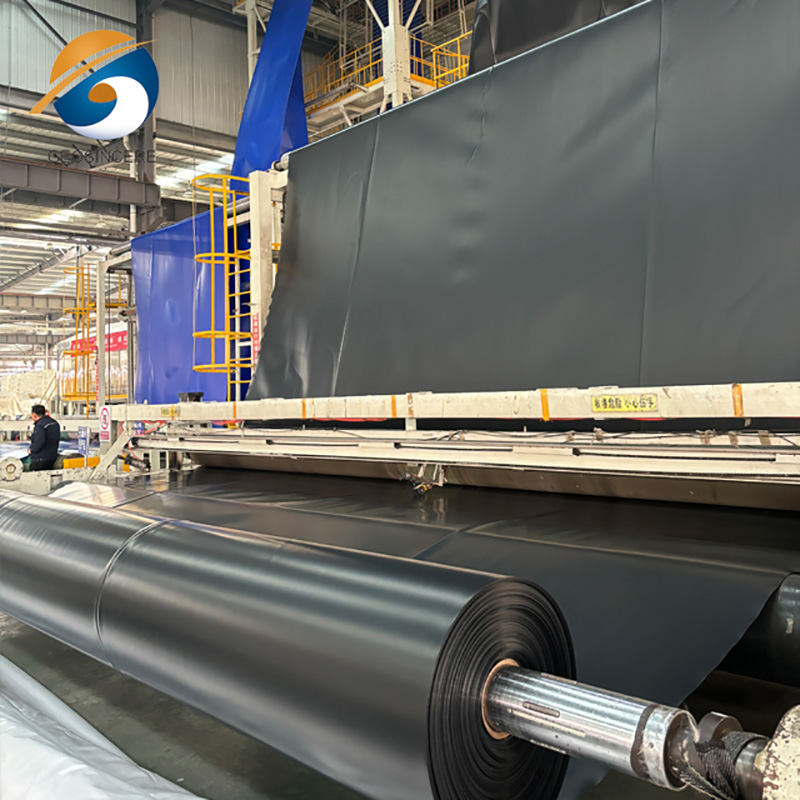

High Density Polyethylene HDPE Geomembrana is a flexible, synthetic liner fabricated from high-density polyethylene (HDPE) resin. It is designed to control fluid or gas migration in a variety of applications by creating an impermeable barrier. Manufactured through advanced extrusion technology, HDPE geomembrana is typically offered in thicknesses ranging from 0.5mm to 3mm and is available in smooth or textured surfaces to suit project-specific requirements.

Key Benefits of High Density Polyethylene HDPE Geomembrana

✅ Superior Chemical Resistance

HDPE geomembrana is resistant to acids, alkalis, oils, and a wide range of solvents, making it ideal for use in aggressive containment environments such as landfills and chemical plants.

✅ Long-Term Durability

With outstanding UV resistance, oxidation stability, and stress crack resistance, High Density Polyethylene HDPE Geomembrana ensures performance for decades — even under extreme climatic conditions.

✅ Exceptional Impermeability

The extremely low permeability of HDPE geomembrana prevents fluid seepage and contaminant migration, helping projects meet strict environmental regulations.

✅ High Tensile Strength

HDPE geomembrana exhibits excellent mechanical strength, withstanding tension, puncture, and load pressures in challenging structural and geotechnical settings.

✅ Easy Installation and Welding

Available in large roll formats, HDPE geomembrana allows for rapid deployment with hot wedge or extrusion welding, ensuring strong, leak-free seams and cost-effective installation.

Applications of High Density Polyethylene HDPE Geomembrana

High Density Polyethylene HDPE Geomembrana is used in a wide range of civil, environmental, and industrial projects:

🏞 Landfill liners and capping systems

🚰 Wastewater treatment ponds

⛏ Mining heap leach pads and tailing dams

🚜 Agricultural water reservoirs and canals

🏗 Tunnel and foundation waterproofing

🌿 Fish ponds and aquaculture farms

🛢 Secondary containment for fuel and chemicals

Whether it's protecting groundwater or securing industrial waste, HDPE geomembrana delivers performance where it matters most.

Technical Specifications (Example)

| Parameter | Value |

|---|---|

| Thickness | 0.5mm – 3.0mm |

| Density | ≥ 0.94 g/cm³ |

| Tensile Strength | ≥ 25 MPa |

| Elongation at Break | ≥ 600% |

| Carbon Black Content | 2–3% |

| UV Resistance | Excellent (≥ 5000 hrs) |

| Seam Strength | ≥ 90% of sheet strength |

| Standard Compliance | ASTM, GRI-GM13, ISO |

Customized sizes and certifications available upon request.

Why Choose Our High Density Polyethylene HDPE Geomembrana?

Our HDPE geomembrana products are manufactured under strict ISO and ASTM quality standards to ensure high performance, long life, and maximum reliability. Backed by years of industry experience, we offer:

✔ Expert engineering support

✔ Competitive factory-direct pricing

✔ Rapid global delivery

✔ Custom roll sizes and thicknesses

✔ Professional on-site installation guidance

Customer Reviews

“The HDPE geomembrana we purchased for our landfill project delivered flawless impermeability and passed all tests. Highly recommended!”

— Carlos M., Environmental Engineer, Chile

“We’ve used HDPE geomembrana in several mining sites. It performs excellently even in the most aggressive chemical environments.”

— Sarah L., Mining Project Manager, South Africa

Order High Density Polyethylene HDPE Geomembrana Today

Don't compromise when it comes to environmental safety and structural integrity. Choose High Density Polyethylene HDPE Geomembrana for your next infrastructure or containment project. Contact us today to request a free quote, sample, or custom engineering consultation.

📞 Fast Response | 📦 Bulk Inventory | 🌍 Worldwide Shipping

HDPE geomembrana is available in various colors, thicknesses, roll widths, and lengths. This allows for customization based on specific project requirements. The color options provide flexibility in design and visibility preferences, while thickness variations cater to different levels of containment needs. Roll widths and lengths can be tailored to suit the dimensions of the project, facilitating efficient installation and minimizing waste.

Overall, HDPE geomembrana offers exceptional durability, flexibility, weldability, and customization options. These qualities make it a versatile solution for industries requiring effective containment barriers in challenging environments.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

Product Specifications

- Material: High Density Polyethylene (HDPE)

- Thickness: Varies based on project requirements (e.g., 0.1mm - 3.0mm)

- Roll Width: Customizable (commonly 1m - 10m)

- Roll Length: Customizable (commonly 50m - 200m)

- Color: Black, Blue, Green (other colors available upon request)

High Density Polyethylene HDPE Geomembrana Features

Excellent Chemical Resistance.

Outstanding Stress Crack Capacity.

Lowest Permeability.

Excellent UV Resistance.

Stable Low Temperature Embrittlement Resistance.

Proven Performance.

Fast Deployment.

Easy Transportation.

ISO9001 Certificated Geomembrana Factory.

Meet or Exceed All Aspects of GRI GM13.

Complete Width and Thickness Specifications.

Competitive Factory Price.

ODM/OEM are Available.

Applications of High Density Polyethylene HDPE Geomembrana

High Density Polyethylene (HDPE) Geomembrana, also known as HDPE Geomembrana, has a wide range of applications across different industries. Some of its key applications include:

1. Landfills: HDPE geomembrana is extensively used as a liner in landfills to prevent the leakage of hazardous materials, such as landfill leachate, into the surrounding soil and groundwater.

2. Mining: In mining operations, HDPE geomembrana is utilized for lining tailings ponds, heap leach pads, and other containment areas. preventing their release into the environment and protecting water resources.

3. Environmental Protection: HDPE geomembrana plays a vital role in various environmental protection projects. It is used for hazardous waste containment, ensuring that pollutants do not seep into the soil or water sources. It is also used in secondary containment systems to prevent leaks and spills from storage tanks and industrial facilities.

4. Water and Wastewater Management: HDPE geomembrana is commonly used in the construction of reservoirs, ponds, canals, and other water containment structures. It helps to prevent seepage and leakage, ensuring efficient water management and conservation. In wastewater treatment facilities, HDPE geomembrana is used as a liner to prevent the migration of contaminants into the surrounding environment.

5. Agriculture: In agriculture, HDPE geomembrana is utilized for applications such as lining irrigation channels, agricultural ponds, and aquaculture ponds. It helps to prevent the loss of water through seepage, improves water efficiency, and supports sustainable farming practices.

6. Civil Engineering: HDPE geomembrana finds applications in civil engineering projects such as canal lining, reservoirs, and stormwater management systems. It provides an impermeable barrier against water and helps to prevent erosion and water loss.

These are just a few examples of the applications of HDPE geomembrana. Its versatility, durability, and impermeability make it a widely used material in many industries where containment and environmental protection are critical.