1.5mm Waterproof Flexible Pond Liner Geomembrane

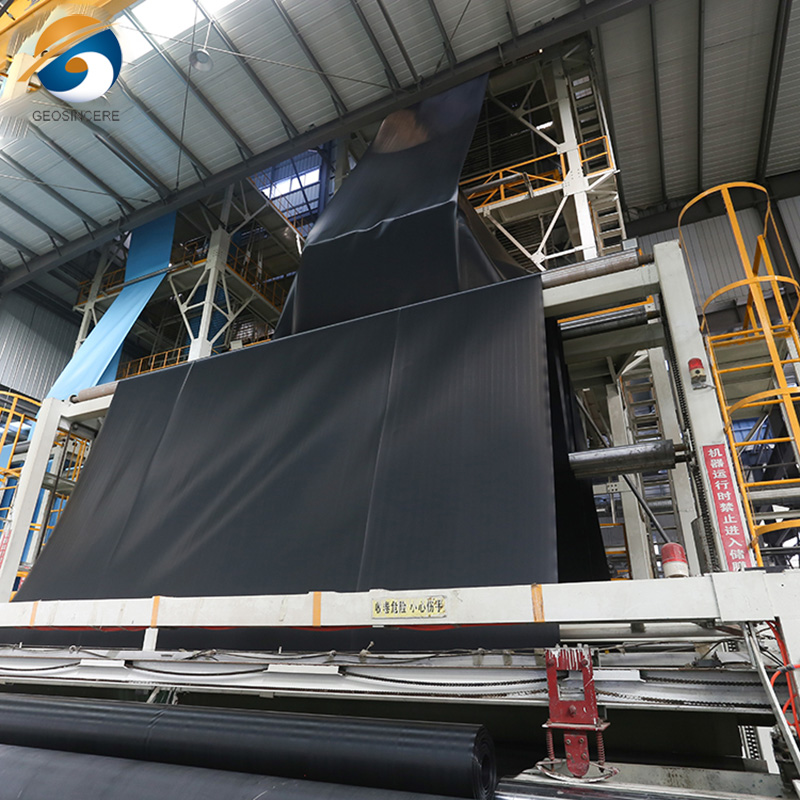

Manufacturing Process

Resin preparation with strict melt index control

Extrusion or blown film production line, continuous molding

Three-layer co-extrusion ensures uniform thickness distribution

Cooling, trimming and online defect inspection

Mechanical testing: tensile, puncture, tear resistance

Roll packaging with project ID traceability

Core equipment: Co-extrusion geomembrane line, automatic flaw detector, GRI test bench.

1.5mm Waterproof Flexible Pond Liner Geomembrane Definition

1.5mm Waterproof Flexible Pond Liner Geomembrane is a high-density or linear low-density polyethylene membrane designed for long-term waterproofing in ponds, aquaculture and water containment engineering. The product offers strong mechanical strength, chemical resistance, and excellent anti-seepage performance.

Technical Parameters & Specifications

| Item | Specification |

|---|---|

| Material | HDPE / LLDPE |

| Thickness | 1.5mm ± 0.1mm |

| Width | Up to 8m single roll |

| Tensile Strength | ≥ 25 MPa (HDPE) |

| Elongation at Break | ≥ 700% (LLDPE) |

| Puncture Resistance | ≥ 600 N |

| Carbon Black Content | 2–3% |

| UV Resistance | ≥ 5,000 hrs aging test |

| Temperature Range | -40°C to +60°C |

| Certification | ISO 9001, GRI-GM13 (HDPE) |

Structure & Material Composition

Polyethylene Base Layer: HDPE/LLDPE anti-seepage membrane

UV Stabilizer: Carbon black formulation for outdoor durability

Antioxidants: Improve aging and thermal stability

Optional: Textured surface for higher friction coefficient

Manufacturing Process

Resin preparation with strict melt index control

Extrusion or blown film production line, continuous molding

Three-layer co-extrusion ensures uniform thickness distribution

Cooling, trimming and online defect inspection

Mechanical testing: tensile, puncture, tear resistance

Roll packaging with project ID traceability

Core equipment: Co-extrusion geomembrane line, automatic flaw detector, GRI test bench.

Industry Comparison

| Material Type | Waterproofing | Flexibility | Service Life | Cost |

|---|---|---|---|---|

| 1.5mm HDPE/LLDPE Geomembrane | ★★★★★ | ★★★★☆ | 20–30 years | Medium |

| Concrete Lining | ★★★☆☆ | ★☆☆☆☆ | 10–15 years | High |

| Clay/Geosynthetic Clay Liner | ★★★★☆ | ★★☆☆☆ | 15–25 years | Medium-High |

| PVC Membrane | ★★★☆☆ | ★★★★★ | 5–10 years | Medium |

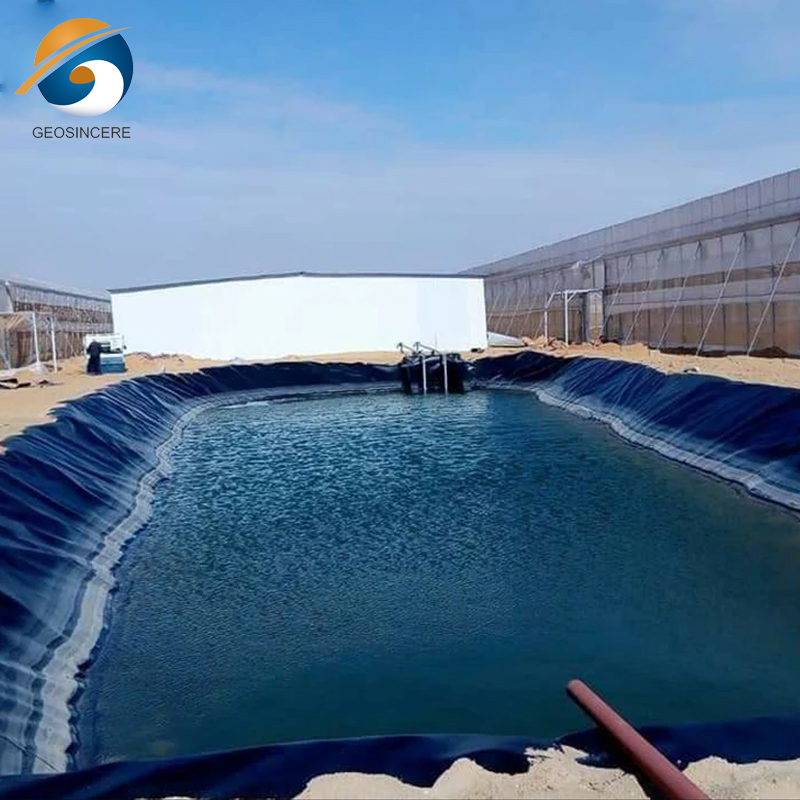

Application Scenarios

Aquaculture ponds and shrimp farms

Landscape and garden ponds

Mining tailing ponds

Landfill cell lining & leachate control

Reservoirs, canals, water tanks

Industrial wastewater containment

Target users:Distributors、Contractors、EPC、水利工程单位。

Core Pain Points & Engineering Solutions

Leakage risks → Multi-layer co-extrusion + seamless high-width rolls reduce joints

UV exposure damage → Carbon-black UV stabilization enhances outdoor durability

Tear/puncture during installation → High puncture resistance & textured options for slope stability

Settlement & ground deformation → Flexible LLDPE versions withstand substrate movement

Risk Warnings & Preventive Measures

Sharp stones must be removed; geotextile recommended as cushion layer

Overlap seams must follow GRI GM13 welding standards

Site quality inspection required:spark test & vacuum box testing

Record installation temperatures:avoid excessive thermal shrinkage

Procurement & Selection Guide

Select HDPE or LLDPE based on ground settlement requirements

Request tensile & puncture test reports according to GRI-GM13

Confirm carbon-black content for long-term UV exposure

Check roll dimensions for minimizing welding workload

Verify project-based warranty & lifetime simulation

Ensure supplier has welding equipment & onsite QC support

Engineering Case Study

A Southeast Asian shrimp farming EPC project required high waterproof reliability under strong UV exposure. 180,000 m² of 1.5mm HDPE geomembrane was deployed with double-seam extrusion welding. Leakage rate reduced by 85% vs. previous PVC liners. 12-month inspection showed no visible crack or joint failure despite soil settlement.

FAQ

What is the service life? → 20–30 years depending on UV and soil conditions.

Is it safe for fish? → Yes, food-grade and non-toxic formulations available.

Minimum roll width? → Up to 8m per roll reduces welding seams.

How to weld? → Hot wedge or extrusion welding under trained supervision.

MOQ? → Normally 5,000–10,000 m² depending on stock.

Lead time? → 10–20 days per container.

Color option? → Black standard; white-coated for visible QC inspections.

How to check leakage? → Spark testing or vacuum box test.

Can be used on steep slopes? → Yes, textured surface recommended.

Transport & storage? → Indoor dry stacking; protect from direct sun before laying.

Request Quotation & Technical Documentation

Contact us for:

Project-based pricing & delivery plans

Technical data sheets (TDS)

Welding guides & installation manuals

Sample rolls for engineering approval

E-E-A-T Author Credentials

Prepared by a geosynthetics application consultant with 10+ years industry experience in hydraulic engineering waterproofing, GRI-GM13 testing, and EPC project technical support for geomembrane selection and installation.