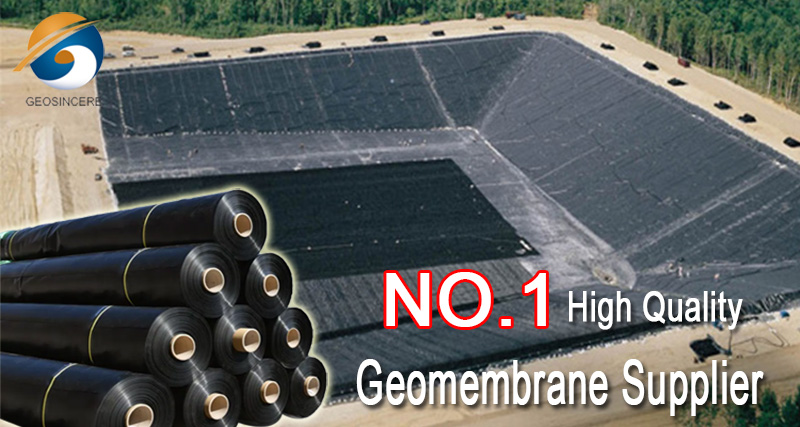

PVC Impermeable Geomembrane Landfill Liner Material

PVC (Polyvinyl Chloride) impermeable geomembrane is a commonly used material for landfill liner systems. It provides an effective barrier to prevent the migration of liquids, gases, and contaminants from the landfill into the surrounding environment. PVC geomembrane has excellent impermeability properties, effectively preventing the penetration of liquids and gases. It acts as a barrier, containing leachate (liquid waste) within the landfill and preventing its migration into the underlying soil and groundwater.

PVC impermeable geomembrane is widely used as a landfill liner material due to its impermeability, chemical resistance, durability, and ease of installation. It plays a crucial role in preventing environmental contamination and protecting groundwater resources from potential pollution associated with landfill operations.

PVC (Polyvinyl Chloride) impermeable geomembrane is a commonly used material for landfill liner systems. It serves as a critical barrier to prevent the migration of contaminants and leachate from the landfill into the surrounding soil and groundwater. PVC geomembrane exhibits excellent impermeability, effectively blocking the passage of liquids, gases, and pollutants. It prevents the leachate, which is the liquid generated from waste decomposition, from seeping into the ground and potentially contaminating the environment.

PVC geomembrane is highly resistant to a wide range of chemicals, including acids, bases, and organic solvents. This property is crucial for withstanding the corrosive nature of landfill waste and ensuring the long-term integrity of the liner system.PVC geomembrane is known for its durability and longevity. It can withstand harsh environmental conditions, such as UV radiation, temperature variations, and mechanical stresses, without significant degradation. This durability ensures the effectiveness and reliability of the liner over an extended period.

PVC geomembrane is flexible and can conform to the contours and irregularities of the landfill site. This flexibility allows for easy installation, enabling a seamless liner system that minimizes the risk of leakage and provides uniform protection.PVC geomembrane can be heat-welded to form strong and secure seams. The welding process creates a continuous liner without weak points, enhancing the overall integrity and impermeability of the system.PVC geomembrane is inert and does not release harmful substances into the environment. When properly managed, it can be an environmentally friendly choice for landfill applications. However, it is important to consider the potential environmental impacts associated with PVC production and disposal.

PVC geomembrane is manufactured under strict quality control measures to ensure consistent material properties and performance. This quality control helps maintain the desired impermeability and reliability of the liner system.PVC impermeable geomembrane is widely used as a landfill liner material due to its impermeability, chemical resistance, durability, and ease of installation. It plays a crucial role in preventing pollution and protecting the environment by containing landfill waste and preventing its migration into the surrounding soil and groundwater.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

PVC Impermeable Geomembrane Landfill Liner Material Features

Excellent Chemical Resistance.

Outstanding Stress Crack Capacity.

Lowest Permeability.

Excellent UV Resistance.

Stable Low Temperature Embrittlement Resistance.

Proven Performance.

Fast Deployment.

Easy Transportation.

ISO9001 Certificated Geomembrane Factory.

Meet or Exceed All Aspects of GRI GM13.

Complete Width and Thickness Specifications.

Competitive Factory Price.

ODM/OEM are Available.

Applications of PVC Impermeable Geomembrane Landfill Liner Material

In modern landfill engineering, effective leachate containment is not only a technical requirement but also a legal and environmental imperative. One of the most trusted solutions for this purpose is the PVC (Polyvinyl Chloride) impermeable geomembrane liner. Engineered for high flexibility and chemical resistance, PVC landfill liners serve as primary barriers in solid waste containment systems. This article explores the material science, structural performance, regulatory standards, and design considerations of PVC geomembrane liners, providing SEO-optimized content for engineers, environmental consultants, and procurement professionals.

What Is a PVC Impermeable Geomembrane?

A PVC geomembrane is a synthetic polymer-based sheet designed to provide an impermeable barrier for fluid containment. In landfill applications, its role is to prevent leachate—liquid that drains from waste—from contaminating surrounding soil and groundwater.

Material Properties:

Thickness Range: 0.75 mm to 2.5 mm

Specific Gravity: ~1.2 g/cm³

Tensile Strength: ≥ 16 MPa (ASTM D638)

Elongation at Break: ≥ 300%

Hydraulic Conductivity: < 1 x 10⁻¹³ cm/s

Working Temperature: -25°C to +60°C

Lifespan: 20–30 years under normal landfill conditions

PVC liners are flexible, weldable, and have excellent stress-crack resistance—critical attributes in engineered landfill designs.

Industry Standards and Certifications

PVC geomembranes for landfill use must conform to both engineering performance standards and environmental protection regulations. Common standards include:

ASTM D7176 – Specification for PVC geomembranes for buried applications

ASTM D4437 – Standard practice for field seaming

EPA Subtitle D – U.S. regulation outlining minimum criteria for municipal solid waste landfills

EN 13361 – European standard for geomembranes used in water containment

ISO 9001 – For quality control in manufacturing

Compliance with these standards ensures reliability and safety across diverse landfill conditions.

Benefits of PVC Geomembrane in Landfill Liners

1. High Flexibility

PVC sheets conform easily to uneven subgrades and landfill contours, reducing stress concentrations and enhancing integrity over time.

2. Low Permeability

The dense molecular structure of PVC results in extremely low fluid and gas transmission rates, essential for leachate containment and odor control.

3. Chemical Resistance

PVC is resistant to a broad spectrum of landfill chemicals, including organic solvents, hydrocarbons, and acids commonly found in decomposing waste.

4. Ease of Fabrication

Pre-fabricated PVC panels can be custom-welded in the factory or on-site, minimizing seam failure risk and installation time.

5. Extended Service Life

When installed correctly and protected from UV exposure, PVC liners can function effectively for 25+ years without significant degradation.

Engineering Design and Installation Considerations

Subgrade Preparation

The base should be free of sharp objects and compacted to at least 90% standard Proctor density.

Use of a geotextile cushioning layer is strongly advised to prevent puncture from subgrade irregularities.

Welding Techniques

Hot air welding and solvent welding are the most common seaming methods.

All seams must undergo nondestructive testing (e.g., air pressure testing per ASTM D5820).

Anchor Trench Design

Anchor trenches along the perimeter must be at least 30 cm deep and 30 cm wide to secure the liner against uplift.

Cover Layer Protection

A protective layer of soil or sand (minimum 15 cm) is usually required to shield the liner from UV rays and mechanical damage.

Regulatory and Environmental Compliance

PVC landfill liners must satisfy local and international regulatory frameworks aimed at protecting groundwater and air quality. These include:

U.S. EPA 40 CFR Part 258 (Subtitle D)

European Landfill Directive 1999/31/EC

UN Basel Convention Recommendations for hazardous waste containment

Failure to use certified geomembranes can result in environmental liabilities, fines, or site shutdowns. Consulting with environmental engineers and submitting design documentation for approval is strongly recommended.

Common Applications

Municipal Solid Waste (MSW) Landfills

Hazardous Waste Disposal Sites

Industrial Sludge Basins

Leachate Collection Reservoirs

Secondary Containment for Tanks and Pipelines

PVC geomembranes are also used in capping systems to isolate landfill tops and reduce rainwater infiltration.

Frequently Asked Questions (FAQ)

Q1: Why choose PVC over HDPE for landfill liners?

A: PVC offers greater flexibility and weldability in cold conditions. While HDPE is stiffer and more puncture-resistant, PVC is easier to install in complex geometries or retrofit situations.

Q2: Can PVC liners resist methane or other landfill gases?

A: Yes. PVC has low gas permeability and resists degradation from methane, hydrogen sulfide, and volatile organics.

Q3: How is seam integrity verified during installation?

A: Seams are tested using air channel pressure testing (dual-track welds) or vacuum box testing as per ASTM guidelines.

Q4: What protective layers are required above the liner?

A: Typically, a drainage geonet and 15–30 cm of soil or gravel are placed above the liner to protect against puncture and UV damage.

Q5: Are PVC geomembranes recyclable after decommissioning?

A: Yes. PVC is recyclable through specialized processes, making it suitable for projects with sustainability goals.

Conclusion

The PVC impermeable geomembrane is a vital material in modern landfill engineering, offering a blend of flexibility, chemical resistance, and long-term performance. Backed by internationally recognized standards and environmental regulations, PVC landfill liners play a critical role in preventing contamination and ensuring regulatory compliance.

Professional Recommendation

For professionals tasked with landfill design, retrofitting, or compliance upgrades, choosing a high-quality PVC geomembrane with proper certification is essential. We recommend consulting with geotechnical experts and suppliers who understand both site-specific challenges and regulatory requirements to ensure successful implementation.