40 mil HDPE Quality Pond Liner Geomembrane

Manufacturing Process

Manufacturing quality directly affects geomembrane service life:

Virgin or controlled recycled HDPE resin blending

High-precision flat die extrusion or blown film extrusion

Thickness calibration and automatic gauge control

Surface cooling and stress relaxation

Inline spark testing and visual inspection

Roll cutting, labeling, and protective packaging

Strict process control minimizes thickness deviation and internal stress.

40 mil HDPE Quality Pond Liner Geomembrane: Engineering Guide

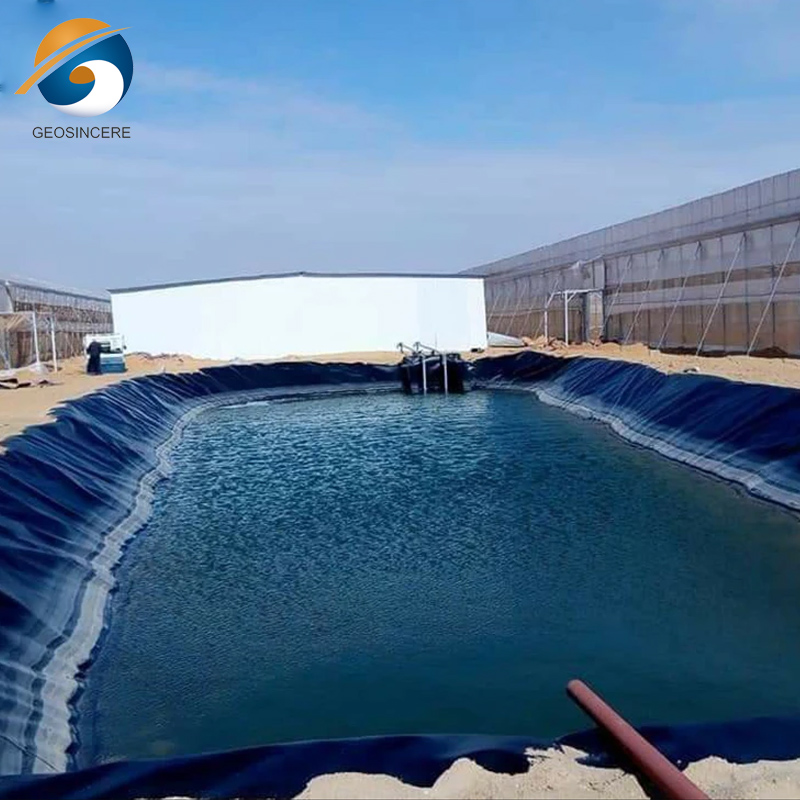

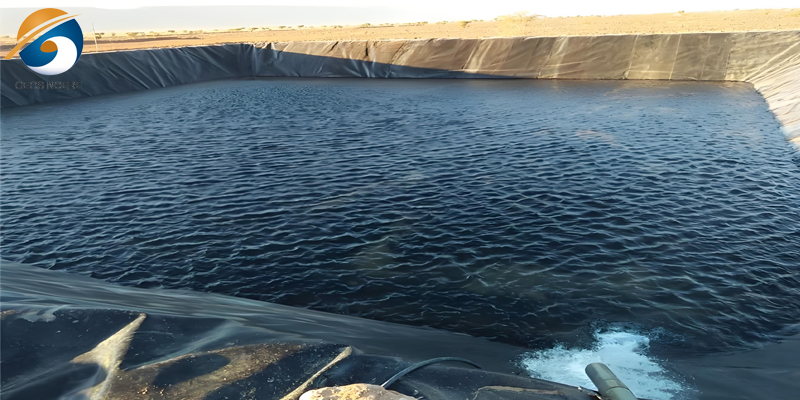

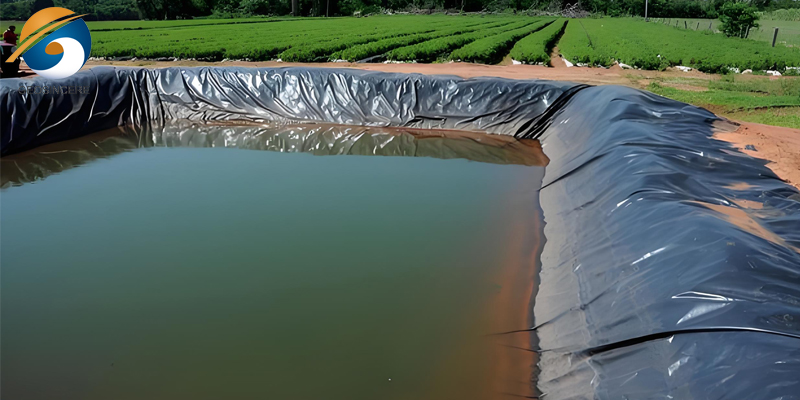

The 40 mil HDPE quality pond liner geomembrane is widely specified in water containment, aquaculture, and environmental protection projects. For B2B buyers, understanding its engineering performance, cost drivers, and long-term risks is essential for compliant, durable, and economically sound installations.

Product Definition

A 40 mil HDPE quality pond liner geomembrane is a 1.0 mm thick high-density polyethylene impermeable membrane designed for liquid containment. It provides reliable hydraulic isolation, chemical resistance, and UV stability for ponds, reservoirs, and environmental engineering applications.

Technical Parameters and Specifications

Key technical parameters for a 40 mil HDPE quality pond liner geomembrane include:

Nominal thickness: 40 mil (1.0 mm)

Density: ≥ 0.94 g/cm³

Tensile strength at yield: ≥ 15 MPa

Elongation at break: ≥ 700%

Puncture resistance: ≥ 320 N

Carbon black content: 2.0–3.0%

Oxidative induction time (OIT): ≥ 100 min

Hydraulic conductivity: ≤ 1 × 10⁻¹³ m/s

These parameters ensure long-term impermeability and structural reliability under field conditions.

Structure and Material Composition

The structural design of a 40 mil HDPE quality pond liner geomembrane focuses on uniformity and durability:

Base polymer: High-density polyethylene resin

Carbon black: UV protection and weather resistance

Antioxidants: Thermal and oxidative aging control

Optional texture: Enhanced interface friction (where required)

Homogeneous single-layer construction ensures consistent mechanical and hydraulic performance.

Manufacturing Process

Manufacturing quality directly affects geomembrane service life:

Virgin or controlled recycled HDPE resin blending

High-precision flat die extrusion or blown film extrusion

Thickness calibration and automatic gauge control

Surface cooling and stress relaxation

Inline spark testing and visual inspection

Roll cutting, labeling, and protective packaging

Strict process control minimizes thickness deviation and internal stress.

Industry Comparison

| Material | HDPE 40 mil | LLDPE 40 mil | PVC Liner |

|---|---|---|---|

| Flexibility | Moderate | High | High |

| Chemical Resistance | Excellent | Very Good | Moderate |

| UV Resistance | Excellent | Good | Limited |

| Service Life | 20–30 years | 15–25 years | 10–15 years |

| Cost Level | Medium | Medium | Low–Medium |

Application Scenarios

Distributors: Standardized pond liner supply for agriculture and landscaping markets

EPC Contractors: Engineered containment systems for reservoirs and lagoons

Environmental Engineers: Secondary containment and seepage control

Aquaculture Operators: Fish and shrimp ponds requiring chemical neutrality

Core Pain Points and Solutions

Pain Point: Premature UV degradation

Solution: Specify certified carbon black content and OIT valuesPain Point: Seam leakage during installation

Solution: Use qualified thermal welding with test seamsPain Point: Puncture damage from subgrade

Solution: Install protective geotextile underlaymentPain Point: Cost overruns due to material waste

Solution: Optimize panel layout and roll width selection

Risk Warnings and Avoidance Recommendations

Avoid uncertified recycled HDPE in critical containment

Do not install without subgrade preparation and smoothing

Protect liner from prolonged exposure before backfilling

Ensure welding parameters match liner thickness

Procurement and Selection Guide

Define containment purpose and fluid chemistry

Confirm thickness requirement based on load and risk

Request full technical data sheet and test reports

Verify manufacturing quality control procedures

Evaluate logistics, roll size, and on-site handling

Assess installer qualifications and welding methods

Align warranty period with project design life

Engineering Application Case

In a 12,000 m² agricultural irrigation pond project, a 40 mil HDPE quality pond liner geomembrane was installed over compacted soil with nonwoven geotextile protection. The system achieved zero leakage after commissioning and reduced annual water loss by over 30%, improving operational efficiency and water security.

FAQ

1. Is 40 mil HDPE thick enough for ponds?

Yes, for most agricultural and landscape ponds with proper subgrade preparation.

2. Can it be used for drinking water?

Only if certified for potable water contact.

3. How long does a 40 mil HDPE liner last?

Typically 20–30 years under normal conditions.

4. Is HDPE better than PVC for ponds?

HDPE offers superior chemical and UV resistance.

5. Does texture improve performance?

Texture improves slope stability but increases cost.

6. Can it handle freeze–thaw cycles?

Yes, HDPE performs well under temperature variation.

7. What welding method is recommended?

Hot wedge or extrusion welding.

8. Is geotextile always required?

Strongly recommended for puncture protection.

9. How is quality verified on site?

Through seam testing and visual inspection.

10. Can panels be factory-prefabricated?

Yes, to reduce field welding and installation time.

Call to Action

For detailed specifications, engineering drawings, pricing, or project samples of 40 mil HDPE quality pond liner geomembrane, please submit your project requirements for professional technical support.

E-E-A-T Author Credentials

This content is prepared by a geosynthetics engineering specialist with extensive experience in HDPE geomembrane manufacturing, quality control, and large-scale water containment and environmental projects worldwide.