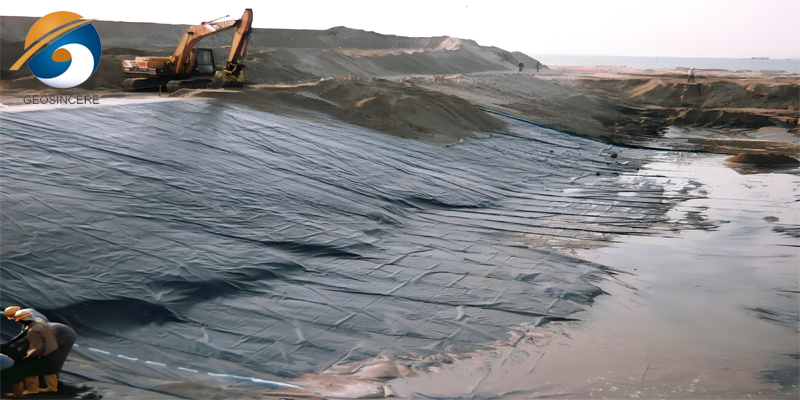

Dam Plastic Lining

Dam plastic lining is a critical factor in current water conservation and administration practices, designed to decorate the performance and toughness of dam structures. Typically made from high-density polyethylene (HDPE) or comparable long lasting materials, these liners serve as impermeable boundaries that efficaciously forestall water seepage and leakage, which can compromise the integrity of the dam and lead to environmental degradation. The flexibility and light-weight nature of plastic lining enable for effortless installation, adapting seamlessly to a number shapes and contours of the dam, which simplifies the development procedure and reduces labor costs. One of the key benefits of dam plastic lining is its amazing resistance to harsh environmental conditions, inclusive of ultraviolet (UV) radiation, chemicals, and temperature fluctuations, which ensures that the liners hold their structural integrity over time. Additionally, these liners are designed to stand up to punctures and tears, offering an brought layer of protection in opposition to doable damage. Their versatility makes them appropriate for a broad vary of applications, from agricultural reservoirs to stormwater administration systems, highlighting their significance in sustainable water administration practices. Furthermore, plastic liners make contributions to increased water best with the aid of stopping infection and making sure protected storage of water resources. As a result, dam plastic lining performs a critical position in merchandising high-quality water conservation and defending the environment, making it an imperative aspect in modern dam engineering and water administration strategies.

Dam plastic lining is an fundamental science in the area of water management, designed to beautify the effectivity and sturdiness of dam buildings whilst stopping water loss and environmental contamination. Constructed specially from high-density polyethylene (HDPE) or different superior polymer materials, these liners act as impermeable boundaries that efficaciously take away seepage and leakage, which can undermine the structural integrity of dams and lead to massive ecological damage. The set up procedure is enormously streamlined due to the light-weight and bendy nature of plastic lining, permitting it to conform without difficulty to the assorted shapes and contours of the dam, as a consequence facilitating faster and greater low-priced construction. One of the standout elements of dam plastic lining is its first-rate resistance to a extensive vary of environmental stresses, along with ultraviolet (UV) radiation, harsh chemicals, and excessive temperature variations, making sure that the liners continue their performance and sturdiness over prolonged periods. Additionally, these liners are engineered to be puncture-resistant, offering an more layer of safety towards attainable injury in the course of set up and operation. Their versatility allows a extensive spectrum of applications, from agricultural water reservoirs to stormwater administration systems, making them integral in quite a number sectors targeted on sustainable water practices. Beyond their structural benefits, plastic liners additionally play a massive function in preserving water exceptional by using stopping contaminants from infiltrating the saved water, therefore promotion safer and cleaner water resources. As a result, dam plastic lining is now not solely a integral element of cutting-edge dam engineering however additionally a key participant in the development of fine water conservation strategies, making sure that we shield our treasured water assets for future generations.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

Dam Plastic Lining Features

1. High Durability: Dam plastic lining is made from high-density polyethylene (HDPE) or comparable materials, making sure it can face up to harsh environmental conditions, together with UV radiation, chemicals, and excessive temperatures.

2. Impermeable Barrier: The main feature of plastic lining is to grant an impermeable barrier that successfully prevents water seepage and leakage, which is critical for keeping the integrity of the dam structure.

3. Flexibility: The light-weight and bendy nature of the lining permits it to conform without difficulty to the contours of the dam. This adaptability helps set up in a variety of terrains and shapes, lowering problems all through the building process.

4. Puncture Resistance: Designed to be puncture-resistant, dam plastic lining minimizes the threat of injury for the duration of set up and operation, making sure long-term overall performance and reliability.

5. Chemical Resistance: The lining is resistant to a large vary of chemicals, making it appropriate for use in various applications, consisting of agricultural and industrial settings.

6. Ease of Installation: The light-weight traits of the cloth make set up simple and efficient, main to decreased labor charges and faster venture completion.

7. Low Maintenance Requirements: Once installed, dam plastic lining requires minimal maintenance, contributing to fee financial savings over time and making sure regular performance.

8. Versatility: Suitable for a number of applications, which includes agricultural reservoirs, stormwater administration systems, and leisure water bodies, improving its utility in one of a kind sectors.

9. Environmental Protection: The lining helps shield surrounding ecosystems by means of stopping water illness and advertising sustainable water administration practices.

10. Customizable Options: Available in a number sizes and thicknesses, dam plastic lining can be tailor-made to meet unique undertaking necessities and website conditions, presenting flexibility in plan and application.

These facets make dam plastic lining an fundamental issue in current water administration and dam engineering, making sure efficiency, sustainability, and environmental protection.

Applications of Dam Plastic Lining

1. Water Reservoirs: Dam plastic lining is extensively used to line water reservoirs, ensuring that water remains contained and free from contamination. This is particularly important for drinking water supplies.

2. Agricultural Ponds: In agricultural settings, these liners are employed to retain water in irrigation ponds, helping to reduce evaporation and water loss, thereby improving irrigation efficiency.

3. Stormwater Management: Plastic lining is used in stormwater retention and detention basins, effectively managing runoff and preventing flooding in urban areas.

4. Aquaculture: In fish farming and aquaculture systems, dam plastic lining creates a controlled environment that prevents water loss and contamination, promoting healthy aquatic life.

5. Recreational Water Bodies: Lining lakes, ponds, and swimming pools with plastic helps maintain water levels while enhancing safety and aesthetic appeal for recreational purposes.

6. Landfill Liners: In landfill sites, dam plastic lining acts as a barrier to prevent leachate from contaminating groundwater, contributing to environmental protection and compliance with regulations.

7. Mining Operations: Used in mining sites to manage water involved in operations, dam plastic lining helps prevent pollution and ensures adherence to environmental standards.

8. Irrigation Systems: Employed in irrigation systems, these liners create effective water catchment areas, reducing waste and improving the overall efficiency of water usage in agriculture.

9. Wastewater Treatment: In lagoons and treatment ponds, dam plastic lining contains wastewater, preventing seepage and ensuring safe treatment and disposal.

10. Temporary Water Storage: Plastic lining is ideal for temporary water storage solutions in emergency situations, such as droughts or natural disasters, providing quick access to water resources.

These diverse applications highlight the versatility and effectiveness of dam plastic lining in various sectors related to water management and environmental conservation.

Product Packing

Selling Packing:Customer's company Logo mark can be designed and added.

Outer Packing:Packed in Double-layer woven bags to ensure smooth arrival and avoid rough handling.

Transport Packing: Put in the container.

Company Profile

Shandong GEOSINO New Material Co.,Ltd (Brand:Geosincere) is the professional geomembrana and geosynthetics manufacturer and wholesaler located in Taian City, Shandong Province, PRChina. We are not a local overseas distributer, we are an professional manufacturer, exporter and wholesaler for such geosynthetic products as geomembana, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc. GEOSINCERE is always committed to geomembrana research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geomembrana and geotextiles for civil, mining, environmental and aquaculture engineering applications.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality geomembrana and other geosynthetics with optimized processes. GEOSINCERE has over 160 employees and its own 24,000 square meters state-of-art manufacturing factory with many automatic geosynthetic production lines, professional machines and testing equipment.Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geomembrana and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.

Hope to be your partner!