Ultimate Guide to HDPE Liner Containment Solutions

HDPE liner have revolutionized how industries manage environmental protection, water conservation, and infrastructure integrity. They are adaptable, long-lasting, and cheap geomembranes, and HDPE sheet have been used to make impermeable barriers for a variety of purposes around the world. This thorough article looks into the nature of HDPE liners, their main benefits, primary uses, and installation and selection procedures - thus your work will be up to the mark with regard to performance and reliability.

We live in a time mainly characterized by heightened environmental awareness along with stricter government regulations– the need for sealing solutions that are able to last long, be reliable, and have a low impact on the environment is at its peak. HDPE (High-Density Polyethylene) liners, which play a key role in the field of geosynthetic engineering, are a major part of this quiet upheaval, having become an essential tool not only in water protection and waste security but also in civil and industrial projects that are at the same time both challenging and ambitious. HDPE geomembranes are more than just plastic sheets - they are like a cutting-edge confluence of polymer science with practical engineering that gives customers the best of all three worlds (high performance, long service, and affordable price), something that has no precedent so far. This published piece is a walking tour into the domain of HDPE liners that covers their scientific bases, their versatile uses, the crucial installation methods, and their decisive role in creating a supporting environment for a sustainable future. To succeed and be compliant with the modern-day regulations, engineers, project managers, environmentalists, and site planners must educate themselves not only on the basic features of HDPE liner technology but also on the advanced ones.

1. The Science Behind the Material – Why Choose HDPE Liner?

Without knowing the specific molecular structure of the plastic it consists of at least, it is impossible to be aware of how extraordinarily well the material performance-wise. High-Density Polyethylene is basically a thermoplastic class of polymers that comes out of the reaction of ethylene monomer being synthesized. This classification "high-density" apparently needs a linear molecular pattern with hardly any branching to explain it. Having this kind of a molecular arrangement makes the dier-chains get closely packed in a highly crystalline fashion, which in turn is why the material has such great tensile strength, can keep its shape quite well, and is resistant to chemical attack if compared to both lower-density variants (LDPE) and linear low-density (LLDPE) counterparts.

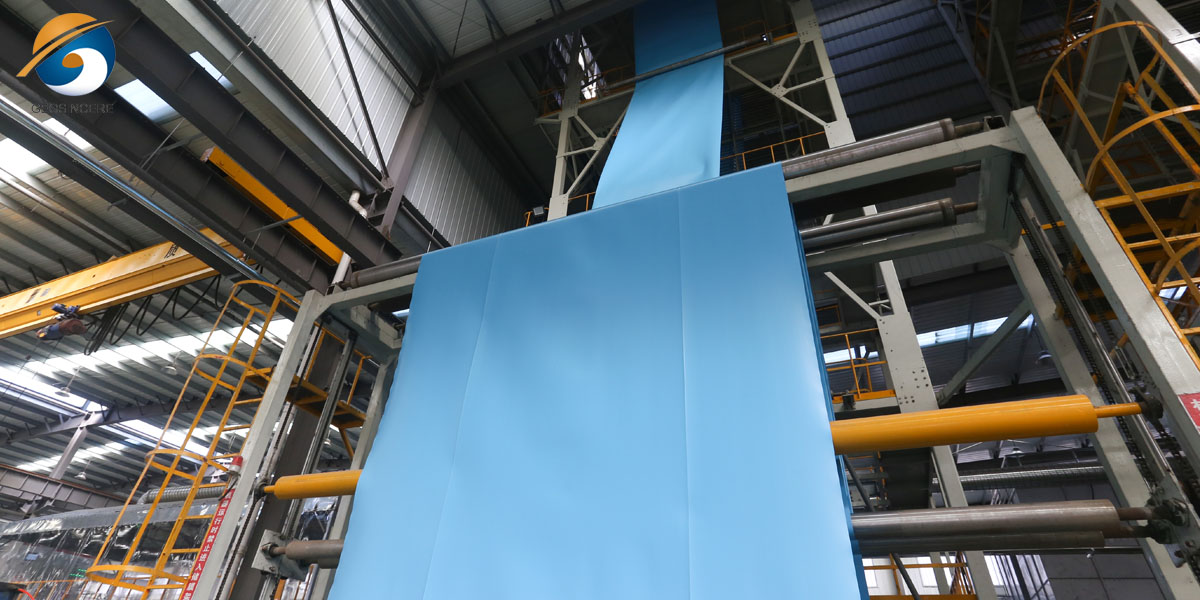

1.1 How HDPE Liner Manufacturing Process Is Key?

There are two ways to make HDPE geomembrane liner: blown-film or flat-die extrusion. Making HDPE resin pellets in this highly controlled environment—particles are usually stabilized with antioxidants while 2-3% carbon black is added causing resistance to ultraviolet (UV)—melting and conversion into a single continuous uniform sheet is done. The advantage of this process is that thickness can be very well controlled and normally ranges from 0.5 mm (20 mil) to 3.0 mm (120 mil) and surface finish as well. Liner surfaces that are textured through co-extrusion or by creating patterns on the surface give an increased interface shear strength which can be very beneficial when a steep slope has to be stabilized.

1.2 Major Performance Characteristics of HDPE Liner

1.2.1 Total Chemical Inertness

HDPE has exceptional capabilities to resist a broad range of chemical agents, such as strong acids, bases, and salts, which qualify it to be an element in the most difficult mining leach pads and industrial waste ponds applications.

1.2.2 Impermeability

This hdpe pond liner is not only water-resistant but also water vapor impermeable, which the permeability coefficient values less than 1 x 10⁻¹³ cm/s can verify, thus providing a water-tight seal.

1.2.3 High Physical Strength

High tensile stress at yielding, very good puncture resistance along with a high surface stress crack resistance (ESCR) of the environment promise the material will stay sound for a long time when used even under pressure and tension.

1.2.4 Long-Service Life

Upon correct formulation, geomembrane pond liner is capable of withstanding long-term exposure to harsh weather conditions, temperature extremes, UV light, and oxidative attack. In most cases, a life span of more than half a century can be expected when it is buried and protected.

2. Comprehensive Applications – Where HDPE Liner Excel

The versatility of HDPE geomembrane sheet makes them the material of choice across diverse sectors. Their primary function is always containment: either preventing valuable substances from escaping or protecting the environment from harmful contaminants.

2.1 Environmental Protection & Waste Management:

This is the most critical application area. HDPE geomembrane liner is the global standard for engineered containment systems.

- Municipal & Hazardous Waste Landfills: HDPE geomembrane sheet serve as the primary and secondary composite liner system base, preventing toxic leachate from migrating into groundwater. They are also used as final cover caps to minimize infiltration and control landfill gas.

- Mining & Metallurgy: Used in tailings storage facilities (TSFs), heap leach pads, and solution ponds to contain process fluids, cyanide solutions, and acid mine drainage, thus protecting surrounding ecosystems.

- Industrial & Radioactive Waste: High density polyethylene pond liner provide secure containment for fly ash, sludge, and low-level radioactive waste, ensuring long-term isolation from the biosphere.

2.2 Water & Hydraulic Engineering:

HDPE is crucial for efficient and safe water management.

- Potable Water Reservoirs: HDPE liner sheet prevent seepage losses and protect water quality in storage tanks, reservoirs, and canal systems, a vital function in water-scarce regions.

- Wastewater & Decorative Lagoons: HDPE membrane sheet line treatment ponds, equalization basins, anaerobic digesters, and artificial lakes, ensuring system integrity and preventing groundwater contamination.

- Aquaculture & Agriculture: HDPE impermeable liner create controlled, hygienic environments for fish/shrimp farming ponds and ensure water efficiency in irrigation storage ponds.

2.3 Civil & Transportation Infrastructure:

HDPE liners provide critical subsurface protection.

- Tunnel & Underground Waterproofing: Polyethylene pond liners used as a moisture barrier in road and rail tunnels to prevent water ingress and structural damage.

- Highway & Landfill Cap Drainage Layers: Often used in conjunction with geonets and geotextiles to manage seepage and gas collection.

- Secondary Containment: Lining berms and dikes around fuel farms, chemical plants, and storage terminals to safely contain potential spills in compliance with environmental regulations (e.g., EPA SPCC rules).

3. Beyond the Basics – HDPE Liner Comparative Analysis and Selection Criteria

While HDPE is a premier choice, selecting the right geomembrane requires a comparative analysis.

3.1 HDPE vs. Other Geomembranes:

- LLDPE: More flexible and stress-crack resistant at low temperatures but generally has lower chemical resistance and higher permeability than HDPE.

- PVC: PVC liner more flexible and easier to seam, but has lower chemical resistance, is susceptible to plasticizer migration (leading to brittleness), and has a shorter lifespan.

- EPDM Rubber: Exceptionally flexible and UV resistant, but has poor hydrocarbon resistance and seams can be less reliable than thermally-fused HDPE seams.

- PP (Polypropylene): Has excellent chemical resistance, especially at higher temperatures, but is more rigid and challenging to field-seam effectively on large projects.

3.2 Selection Checklist for Project Specifiers:

- Chemical Compatibility: Match the hdpe geomembrane pond liner to the long-term chemical exposure profile.

- Site-Specific Stresses: Consider puncture potential, settlement, and slope angles. Textured HDPE may be required for steep slopes.

- Climate Conditions: Evaluate temperature extremes, UV exposure, and installation weather.

- Regulatory Requirements: Ensure the material meets or exceeds relevant standards (e.g., GRI GM13, ASTM standards for HDPE).

- Lifecycle Cost Analysis: Factor in not just initial material cost, but also installation speed, expected service life, and maintenance needs. HDPE liner pond often provides the lowest total cost of ownership.

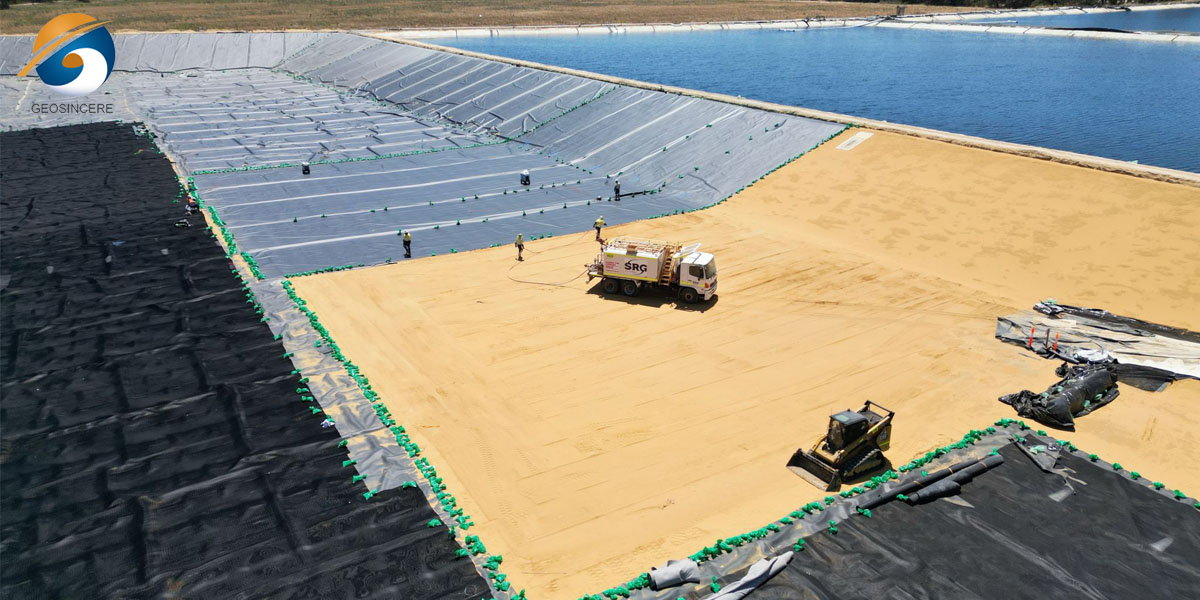

4. The Art and Science of Installation – HDPE Liner A Step-by-Step Protocol

The performance of an HDPE liner is only as good as its installation. Meticulous execution is non-negotiable.

Phase 1: Comprehensive Subgrade Preparation

The subgrade must be engineered to provide a stable, uniform, and smooth foundation. This involves:

- Compaction: Achieving ≥95% Standard Proctor density to minimize differential settlement.

- Finishing: Creating a smooth, firm surface free of sharp rocks, roots, or debris. A protective geotextile cushion layer is often recommended over rocky or uneven subgrades.

- Drainage System Installation: Placing underliner collection pipes and materials as per design.

Phase 2: Liner Deployment and Welding – The Critical Operation

High density polyethylene liner is unrolled and anchored. Seaming is the most critical quality control point.

- Fusion Methods: Dual Hot Wedge Welding is the primary method, creating two parallel seams with an air channel for pressurization testing. Extrusion Fillet Welding is used for details, patches, and repairs.

- Quality Assurance/Quality Control (QA/QC): A rigorous program is mandatory:

- Seam Testing: Every inch of seam is tested. Non-Destructive Testing (NDT) includes air pressure testing of the channel and vacuum box testing. Destructive Testing (DT) involves cutting out sample welds periodically for shear and peel strength testing in a lab.

- Material Certification: Verification of factory test reports for thickness, density, and tensile properties.

Phase 3: Protection and Backfilling

Once tested and approved, the high density polyethylene geomembrane must be protected immediately.

- Geotextile Protection Layer: A non woven geotextile is often laid over the liner to protect it from the backfill material.

- Controlled Backfilling: Using specified, clean fill material placed and compacted with equipment that will not damage the liner. Procedures must prevent rutting and localized stress.

5. The Future of HDPE Liner – Innovation and Sustainability

The industry is transitioning to tackle new challenges.

5.1 Enhanced Materials

Development of HDPE resins with increased stress crack resistance (HSCR) and enhanced flexibility for cold regions.

5.2 Smart Liner Systems

The integration of leak location detection systems (LLDS) using electrical conductivity or fiber-optic cables to render the monitoring of liner integrity instantly.

5.3 Sustainability Focus

There is ongoing research into utilizing recycled HDPE content in non-critical applications and making the end-of-life recyclability of geomembranes better. The long service life and prevention of pollution that polyethylene geomembrane provide are already very significant contributions to the sustainable development goals through the protection of soil and water resources.

Conclusion: Investing in Long-Term Integrity

Putting money into an HDPE liner means investing in a project’s basic integrity and environmental soundness. The record of its success, which is the result of material science and thorough engineering practices, makes it the most reliable barrier material for the most challenging containment problems worldwide. As the community's drinking water is secured, industrial byproducts are safely encapsulated for generations, hdpe liner material provide the dependable, durable performance that both modern engineering and environmental protection call for.

Where the project failure is absolutely not an option, the specification of a top-notch Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) HDPE liner and the cooperation with experienced, certified installers is the final gesture paving the way for the achievement of not only sustainable success, but also regulatory compliance and peace of mind.