Why Filter Fabric Under Pavers Matters Most?

When starting a paver project for a patio, walkway, or driveway, attention is naturally drawn to the most visible factors: the color, texture, and pattern of the pavers. Homeowners and contractors go through, samples, visualizing the end effect that will beautify their outdoor living space. What they don't see, however, is a whole other world underneath this gorgeous, top layer, full of vital elements that will decide whether the project will be successful or fail in the long run. Among these, one of the most debated, misunderstood, yet fundamentally essential elements is filter fabric under pavers . This protective layer is a hardscape hero that your pavers don't recognize, and it's the proper use of this geotextile that makes the difference between a stable installation that lasts for years and a sinking, weedy, mud-filled mess.

Firstly, in order to understand the role of filter fabric, one has to first understand what makes up a good paver base. The construction of a good base is like an onion with several layers and it normally includes the compacted native soil (subgrade), a layer of coarse gravel for the foundation, a layer of finer gravel (most often coarse sand) for leveling and bedding the pavers, and finally, the pavers. It is at the interface between the native soil and the gravel base where filter fabric performs its most vital functions.

1. Filter Fabric Under Pavers The Core Functions: Separation and Filtration

The most basic are the 2 core functions of geotextile or filter fabric: separation and filtration.

1.1 Separation: Preventing the Mixing of Layers

Envision a scenario, where you place the gravel layer of your pavement directly over a soft soil that is rich in clay. The aforementioned situation, the weight of the pavers along with the dynamic forces of foot traffic, vehicles, and freeze-thaw cycles will work together to make the gravel penetrate deeper. At the same time, the soft, wet subgrade soil will invade the spaces between the gravel pieces. This action is referred to as "pumping." As time goes on, the clear, stable layer of gravel turns into one which is mixed with soil particles. The level of structural integrity that the base had, is now lowered because the base is essentially a mixture of soil and gravel particles. So instead of having a good solid base, you now have a mixture of soil that retains water and loses stability. The consequential uneven settling, sinking, and the waving, thus unstable paver surface that results is not only an eyesore but dangerous as well.

Geotextile fabric is a strong barrier that is able to physically stop this process from happening. It separates the gravel from the subgrade soil letting neither of them contaminate the other. The non woven geotextile fabric keeps the base from becoming loaded with fines, thus it is still capable of supporting the designed loads and therefore will provide a safe, level, and stable surface for a long time.

1.2 Filtration: Allowing Water Passage While Blocking Soil

Water is the biggest enemy that a construction project will have to face. There is no bargaining on good drainage. If water makes its way through the joints of the pavers and down to the base, it must be let out through the subsoil. If water pools underneath, it can cause frost heave in areas that are subject to freezing, erosion, and the destabilization of the base.

Geo fabric is made to be a breathable material. It is not a membrane that repels water. The way it is made, its woven or non-woven structure is conceived to be open to water which can come and go free of any obstruction. However, while the non woven geotextile is permeable to water, it is impermeable to fine soil particles coming from the subgrade. This is the "filtration" aspect. If there was no such filter, the soil particles that the water takes along with it would find their way underneath the base and create voids. These voids are the places where subsidence and settling will occur over time. The non woven landscape fabric does this work while it allows the water to pass through it, it stabilizes the soil underneath and at the same time prevents the erosion of the subgrade and the occurrence of those empty pockets which are the cause of instability.

2. Debunking the Controversy: To Use or Not to Use?

A common point of contention in hardscape circles is whether nonwoven geotextile fabric is always necessary. Some experienced installers argue that for projects on stable, well-draining, granular soils (like sandy loam), the fabric may be an unnecessary expense. They contend that a sufficiently thick and well-compacted gravel base can function without it. While this can be true in ideal, specific conditions, it is a significant gamble. Soil conditions can change over time, and water can find new paths. The small upfront cost of geotextile drainage fabric is a cheap insurance policy against the exorbitant cost and labor of future repairs.

The argument against geofabric often stems from its misuse rather than its inherent properties. The most valid criticism arises when fabric is installed in the wrong location within the base system.

3. Where NOT to Place Filter Fabric Under Pavers

This is perhaps the most crucial technical point of this discussion. Geotextile filter fabric should never be placed between the gravel base layer and the sand bedding layer.

Placing geotextile landscape fabric here creates a catastrophic failure point. The sand bedding layer's function is to allow for the slight micro-adjustments of pavers during installation and compaction. It provides a uniform, flexible surface. When a non woven filter fabric separates the sand from the gravel, it creates a "slip plane." The sand, unable to properly knit with the gravel below, shifts and moves independently. This lack of a cohesive bond leads to an unstable surface where pavers will rock, tilt, and sink under load. The entire system loses its unified strength. The correct placement is always, without exception, directly on top of the excavated and compacted subgrade, before the first layer of base gravel is installed.

4. Choosing the Right Filter Fabric Under Pavers

Landscaping fabrics are not the same. Using a cheap, lightweight weed barrier as a vital structural component is definitely asking for trouble. These fragile geo tech fabric is torn easily when gravel is being installed and also they quickly deteriorate, thus, they fail their primary function. The geotextile drainage for your pavers should be a heavy-duty, non-woven geotextile fabric.

4.1 Non-woven vs. Woven

The reason is that non woven geotextile filter fabric, which are composed of synthetic fibers that are randomly oriented and needle-punched together, have better characteristics for paver bases than woven fabrics. In terms of permeability, filtration, and strength, these fabrics are also very durable enough to withstand the installation process. On the other hand, woven geotextile that look like burlap are very strong but the flow-through rates can be lower, and hence, if are not selected carefully, drainage might be affected.

4.2 Weight and Strength

A geo textile material with a high grab tensile strength and puncture resistance should be the one you choose. A fabric weight of 4 ounces per square yard or more is a good starting point for residential patios and walkways. In case of the areas such as the driveway where heavy loads will be put, the fabric of 8 ounces or heavier should be used. Geotextile filter cloth is always a good idea to check the manufacturer's specifications for the application you have in mind.

4.3 Permeability

The driveway fabric stabilization geotextile fabric must allow a very high rate of water flow so that it does not hinder water infiltration. Leading geotextile manufacturers will willingly offer this information to their customers.

5. Filter Fabric Under Pavers Installation Best Practices

Proper installation is easy if you follow the steps and instructions carefully:

5.1 Excavate and Compact

Excavate to the necessary depth, not forgetting to add up the paver, sand, and gravel layers. Compact the exposed subgrade thoroughly with a plate compactor to create a firm, stable starting point.

5.2 Lay the Fabric

Place the filter fabric over the compacted subgrade in long rolls. Adjacent fabric strips should be overlapped by 12 to 18 inches or even more for the assurer of complete coverage and the prevention of soil pushing through the seams.

5.3 Secure and Proceed

Fabric staples or stakes can be used to hold the fabric tightly, especially on slopes or windy days. This can not only keep it from moving or folding but also from being damaged by the first gravel layer, which you will add later.

5.4 Add Base Material

Put the first layer of gravel right on top of the fabric and then spread it out. Even though the fabric is strong, it is still better to exercise some caution using machinery like a skid-steer, so as not to tear it. After the fabric has been covered with a few inches of gravel, it is fully protected.

5.5 Beyond the Base: A Note on Weeds

Filter fabric under pavers being a separation and filtration agent, it can also be considered a secondary, long-term defense against weeds. Weeds in paver joints usually come from seeds that have been blown in from above or have been transported in with the sand. However, they can also come from seeds that are present in the subgrade soil or from roots that grow upward. The fabric serves as a physical barrier to the weeds which are trying to grow from below. It is not a complete weed control solution but significantly limits one potential source and thus makes the work of maintenance less hard.

Conclusion

Compared to the overall cost of a paver project, the price of a top-notch roll of filter fabric is barely noticeable—most of the time, it is less than 1% of the entire project budget. Nevertheless, the role it plays is huge. It is the final point that separates a solid and stable base from a base that is going to fail. By quietly doing the essential works of separation and filtration, it guarantees that the elegance and the utility of your pavement solution will be your share for the next 40 years or so.

If you decide to put your money into pavers, it means that you are buying a landscape feature that will last for years to come. Do not allow that investment to crumble from beneath your feet. Demand the support that is always there but never seen: a carefully installed layer of heavy-duty filter fabric.

Choosing a Good Geotextile Supplier :

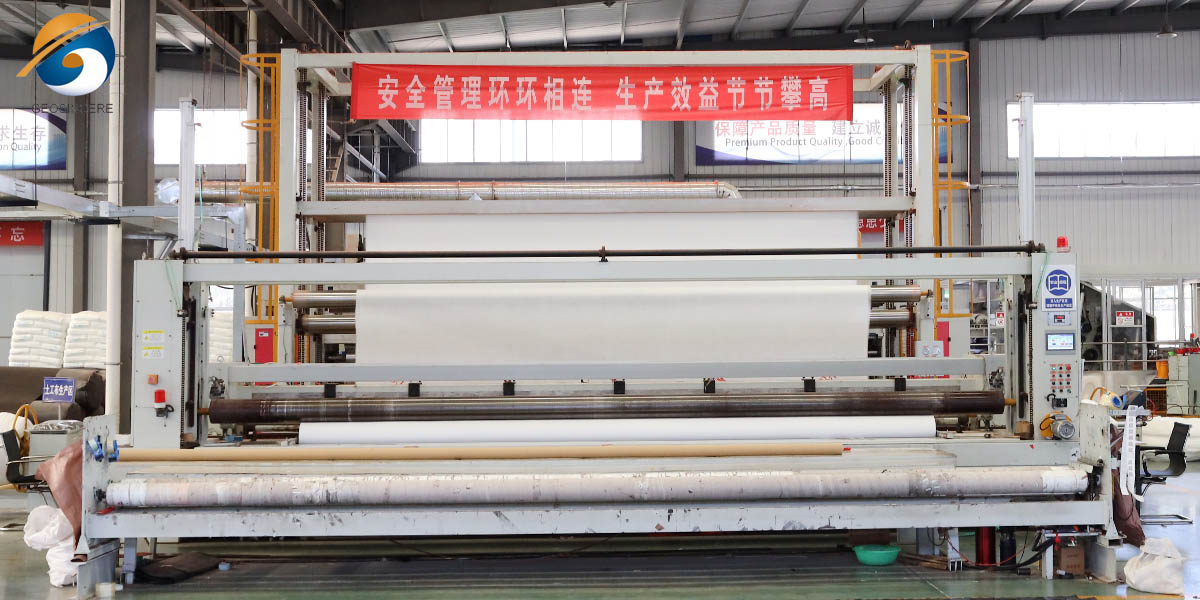

Shandong Geosino New Material Co., Ltd (GEOSINCERE Geosynthetics) is a professional Geosynthetic clay liners manufacturer and wholesale supplier of geosynthetics, located in Shandong Province, China. We are a professional manufacturer, exporter, and wholesaler of geosynthetic products such as HDPE Pool Liner, geotextiles, geogrids, geocells, geosynthetic clay liners (geosynthetic clay liners), drainage boards, etc.

We have been exporting Geosynthetic clay liners and geosynthetics to more than 60 countries such as Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Switzerland, Mongolia, etc. They have chosen GEOSINCERE Geosynthetics as their partner for more than 10 years.