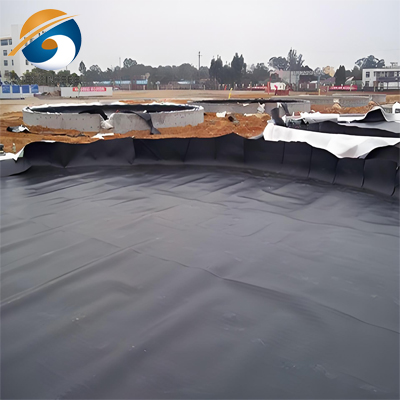

High Density Polyethylene Geomembrane Dam Liner

High density polyethylene geomembrane plays an important role as an anti-seepage membrane in dam construction. It is usually used as the main anti-seepage layer of dams to prevent water leakage and ensure the structural safety of the dam. HDPE geomembrane has excellent permeability resistance, chemical erosion resistance and aging resistance, which can block water bodies reliably for a long time, and is an ideal material for dam seepage control. In addition, high-density polyethylene geomembrane is easy to install and has high construction efficiency, which can effectively reduce the construction cost of dam projects. In the construction of dam engineering, high-density polyethylene geomembrane ensures the safety of the dam on the one hand, and improves the economy of engineering construction on the other hand, and has been widely used in the field of dam construction.

In the modern era of infrastructure and environmental protection, High Density Polyethylene Geomembrane Dam Liner has become the industry standard for dam sealing and water containment. Engineered for exceptional performance, this liner offers unmatched durability, chemical resistance, and impermeability—making it ideal for a broad range of dam and reservoir applications.

If you're seeking a reliable, cost-effective, and eco-friendly solution for dam construction or rehabilitation, the High Density Polyethylene Geomembrane Dam Liner is your answer. This article delves into everything you need to know about this innovative product, including its features, benefits, installation processes, and why it is the top choice among engineers and environmental experts.

What is High Density Polyethylene Geomembrane Dam Liner?

A High Density Polyethylene Geomembrane Dam Liner is a synthetic liner or barrier made from high-density polyethylene (HDPE) resin. It is primarily used to control fluid or gas migration in various engineering and environmental applications. Its high tensile strength and chemical stability make it especially suitable for dam lining, where long-term performance is critical.

With a density greater than 0.94 g/cm³, HDPE geomembranes provide a robust and puncture-resistant barrier that ensures zero leakage. They are designed to withstand harsh weather conditions, UV radiation, and prolonged exposure to chemicals, making them a preferred choice for permanent water containment structures.

Why Choose a High Density Polyethylene Geomembrane Dam Liner?

The High Density Polyethylene Geomembrane Dam Liner is favored for numerous reasons:

1. Exceptional Impermeability

The primary function of a dam liner is to prevent water seepage. HDPE geomembranes offer excellent impermeability, ensuring water remains securely contained within the reservoir or dam basin.

2. Superior Chemical Resistance

HDPE is chemically inert, making the liner resistant to acids, alkalis, and hydrocarbons. This property is particularly useful in regions where chemical contamination of water sources is a concern.

3. UV and Weather Resistance

The High Density Polyethylene Geomembrane Dam Liner is UV-stabilized, providing long-term durability even when exposed to direct sunlight and extreme temperatures.

4. High Tensile Strength and Puncture Resistance

HDPE geomembranes can withstand heavy loads and mechanical stresses without tearing. This durability is vital for large-scale dam structures where integrity must be maintained for decades.

5. Cost-Effectiveness

Compared to traditional lining materials such as concrete or clay, the High Density Polyethylene Geomembrane Dam Liner offers a more economical solution with lower maintenance costs.

Applications of High Density Polyethylene Geomembrane Dam Liner

The versatility of the High Density Polyethylene Geomembrane Dam Liner enables it to be used in a wide array of applications:

Earth dams and rock-fill dams

Agricultural irrigation ponds

Hydropower reservoirs

Water retention basins

Industrial wastewater containment

Landfill leachate collection ponds

Whether for new dam construction or the retrofitting of existing structures, HDPE geomembranes are the go-to solution for water sealing and environmental safety.

Installation Guidelines for High Density Polyethylene Geomembrane Dam Liner

Proper installation is crucial to the performance of any geomembrane system. Here's a general overview of how to install a High Density Polyethylene Geomembrane Dam Liner:

1. Surface Preparation

Clear the subgrade of any sharp objects, roots, or stones.

Ensure the surface is smooth and compacted.

2. Unrolling and Positioning

Carefully unroll the HDPE liner to avoid stretching or tearing.

Position the liner according to the dam layout plan, allowing for overlaps.

3. Welding and Seaming

Use hot wedge or extrusion welding machines to bond the sheets.

Conduct quality control tests such as vacuum box and air pressure testing.

4. Anchoring and Covering

Anchor the edges into trenches to prevent uplift.

In some cases, cover with soil or ballast to protect against physical damage.

Technical Specifications of High Density Polyethylene Geomembrane Dam Liner

| Property | Standard Value |

|---|---|

| Thickness | 0.5 mm to 3.0 mm |

| Density | ≥ 0.94 g/cm³ |

| Tensile Strength | ≥ 25 MPa |

| Elongation at Break | ≥ 700% |

| Puncture Resistance | ≥ 600 N |

| Carbon Black Content | 2.0 – 3.0% |

| UV Resistance (Xenon Arc) | ≥ 90% retained strength (5000 hrs) |

| Chemical Resistance | Excellent |

Always consult the manufacturer’s datasheet for exact specifications tailored to your project.

Environmental and Regulatory Compliance

One of the key advantages of using a High Density Polyethylene Geomembrane Dam Liner is its alignment with international environmental regulations. HDPE geomembranes are:

Non-toxic and environmentally safe

Approved by agencies such as EPA and ISO

Reusable and recyclable at the end of their lifecycle

These features make them ideal for projects with stringent sustainability goals and compliance requirements.

How to Select the Right High Density Polyethylene Geomembrane Dam Liner

When choosing a High Density Polyethylene Geomembrane Dam Liner, consider the following factors:

Project Size and Location: Terrain, climate, and expected load.

Thickness Requirements: Heavier-duty projects require thicker liners.

Chemical Exposure: Type and concentration of potential contaminants.

UV Exposure: Projects in sunny regions may need enhanced UV stabilization.

Budget and Lifecycle Costs: Balance between initial investment and long-term savings.

Consulting with a qualified geomembrane supplier or civil engineer can help optimize your selection.

Maintenance and Longevity

The High Density Polyethylene Geomembrane Dam Liner is renowned for its low-maintenance nature. Routine inspections and minor repairs can ensure the liner remains intact for over 30 years. Key maintenance tips include:

Regular inspections for signs of physical damage

Prompt repair of tears using compatible HDPE patches

Periodic testing of seams and edges

Vegetation control around the dam area to prevent root intrusion

Where to Buy High Density Polyethylene Geomembrane Dam Liner

To guarantee quality and compliance, purchase your High Density Polyethylene Geomembrane Dam Liner from certified manufacturers with proven track records in the industry. Look for providers who offer:

ISO and ASTM-certified products

Installation support and supervision

Comprehensive warranty coverage

Technical consultations and site visits

Avoid low-cost, untested alternatives that could compromise your project's structural integrity and environmental safety.

Conclusion

The High Density Polyethylene Geomembrane Dam Liner is a cutting-edge solution for dam lining that combines exceptional impermeability, durability, and environmental safety. Whether you're constructing a new dam or rehabilitating an aging reservoir, HDPE geomembranes offer unmatched performance at an affordable cost.

By choosing a High Density Polyethylene Geomembrane Dam Liner, you're investing in a product that meets the highest standards of engineering, sustainability, and long-term reliability.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

Advantages of High Density Polyethylene Geomembrane Dam Liner