High Density Polyethylene HDPE Liners

High Density Polyethylene HDPE Liners are dependable geomembrane materials fabricated from high-grade polyethylene resin through a cutting-edge extrusion method. They offer superb barrier properties, chemical resistance, and durability to serve environmental, industrial, and water management applications.

- Exceptional Chemical Resistance: HDPE liners have resistance properties against acids, alkalis, salts, hydrocarbons, and different industrial chemicals, thus guaranteeing their efficiency over a long period of time even when subjected to aggressive conditions.

- Excellent Weldability: The smooth surface facilitates perfect thermal fusion welding resulting in strong and durable, leak-proof seams at the time of installation.

- Durable Service Life: With correct installation, HDPE liners will generally continue to perform reliably for 20 to 30 years or even more, depending on the conditions of use.

- Flexible Specifications: Offered in different thicknesses, widths, and lengths stagger various application needs.

High Density Polyethylene HDPE Liners represent a top-tier geomembrane material that combines advanced extrusion technology with quality checked processes to produce a product that delivers superior impermeability, high durability, and excellent chemical resistance in even the most challenging environmental, industrial, and water management situations. Thanks to their outstanding mechanical strength, easy weldability, and ability to retain their performance over time, HDPE liners serve as a highly effective barrier against leaks and contamination, thereby making them a reliable choice under severe operating conditions. Consequently, they have become a staple in providing containment solutions for landfills, mining operations, water storage facilities, sewage treatment plants, and other critical infrastructures.

1. High Density Polyethylene HDPE Liners Material & Manufacturing

1.1 Raw Material Grade

HDPE liners are fabricated from high-grade polyethylene resin, encompassing 100% virgin materials or high-quality certified raw materials. These resins deliver excellent molecular stability, high density, and strong mechanical performance, thus ensuring not only the consistency of product quality but also its durability over time.

1.2 Advanced Production Technology

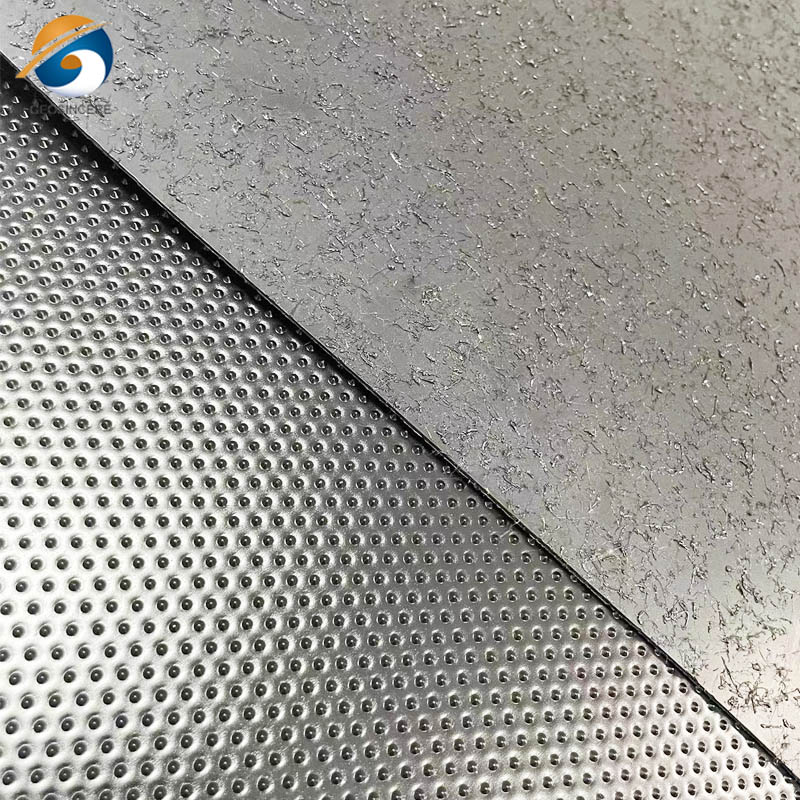

These hdpe geomembrane go through sophisticated extrusion and calendering methods producing a consistent thickness, a smooth surface, and stable physical characteristics. The use of automated systems in production also diminishes flaws and ensures manufacturing is done with a high level of accuracy.

1.3 Virgin Material and Material Purity

In order to meet the highest performance standards, hdpe geomembrane liner is produced from 100% virgin raw materials with no recycled content allowed. This ensures the product will have great chemical resistance, excellent UV stability, and its life will be significantly longer, especially when it is used in sensitive environmental and industrial settings.

1.4 Strict Quality Control System

Raw material inspection, in-process observation, and final product evaluation are some of the measures used in the comprehensive quality control system that covers the production stage from start to finish. Every batch is subjected to thickness, tensile strength, elongation, and surface quality testing to confirm conformity with the international standards such as ASTM and ISO.

1.5 Consistency and Traceability

Each batch of production is documented and can be traced, thus full traceability of material origins, processing conditions, and test results is ensured. As a result, stable performance and dependable quality are guaranteed for each HDPE liner supplied.

2. High Density Polyethylene HDPE Liners Physical & Mechanical Properties

2.1 Tensile Strength

HDPE geomembrane sheet have remarkably high tensile strength which is evident in their ability to handle heavy tensile forces during the installation process as well as throughout the lifespan of the product. Thanks to this attribute such hdpe membrane sheet do not give in to stretching, deformation, or failure of their structure when put under the influence of heavy loads or hydraulic pressures.

2.2 Puncture Resistance

Being highly resistant to puncture, hdpe geomembrane pond liner effectively prevent any kind of mechanical damages that may be caused to them by sharp stones, roots, or different types of machinery. When it comes to applications where the bare ground is uneven, the backfill materials are very dense, and the area is either a mine or landfill, this particular characteristic makes a significant difference.

2.3 Tear Resistance

HDPE geomembrane have a high tear resistance and thus they do not allow cracks to propagate nor material to fail when they are subjected to localized stresses or accidental damage. Overall, this feature of geomembrane sheet has a significant impact on the durability of the material as well as on the reduced risk of leakage.

2.4 Elongation at Break

Having a high level of elongation at break, hdpe geomembrane liner when loaded can be extended to a great extent without using breaking them. This property of flexibility enables the hdpe geomembrane sheet to be used in areas where the ground might settle, the thermal expansion will take place, and minor structural movement might occur without any cracking coming of the liner.

2.5 Impact Resistance

HDPE liners possess high impact resistance which is a very important characteristic especially in cases when sudden mechanical shocks occur during the processes of transportation, installation and operation. With hdpe liner sheet, stable performance under challenging construction environments can be guaranteed.

2.6 Dimensional Stability

During temperature changes and long-term loading, the material continues to possess its shape and size. A very low coefficient of thermal expansion and minimal shrinkage results in the preservation of hdpe dam liners integrity and seam alignment.

3. High Density Polyethylene HDPE Liners Impermeability & Sealing Performance

3.1 Excellent Impermeability

High density polyethylene liner is highly impermeable and create a double-barrier against water and gases. This molecular density of the materials hinders the migration of contaminates allowing the liners to play their role of isolation effectively in reservoirs, landfill, mining ponds, and wastewater plants.

3.2 Superior Welding Performance

Since the surface of high density polyethylene geomembrane is smooth and homogeneous, they can be welded by methods of hot wedge welding or extrusion welding very well. With these techniques, there is the control of the uniform melting and adherence of the parts, thus a strong and reliable weld is formed at the seams during installation.

3.3 High Seam Strength

The seams of a carefully welded polyethylene geomembrane have great tensile and shear strength, sometimes even stronger than the parent material. These homogenous seams structures reduce the risk of joint failure and provide long-lasting sealing reliability.

3.4 Leak Prevention Capability

Thus, with installation carried out only by professionals and their superior skills in controlling the quality of both the process and the product being a weld, hdpe geo membrane is totally effective in preventing leakage even when exposed to a very high hydraulic pressure. The use of both non-destructive and destructive methods for the testing of seams further guarantees system integrity.

3.5 Long-Term Sealing Stability

HDPE liner material is very stable in their sealing performance when faced with temperature fluctuations, chemical exposures, and mechanical stresses. In this way, they can ensure the continuous impermeability of the lining system throughout its entire service life.

4. High Density Polyethylene HDPE Liners UV & Weather Resistance

4.1 UV Radiation Resistance

HDPE smooth geomembrane is manufactured utilizing carbon black of premium quality and UV stabilizers to provide an outstanding defense against ultraviolet radiation. Hence, the material does not deteriorate, nor does the surface crack, or the mechanical strength drop even after long-term exposure to sunlight.

4.2 Anti-Aging Performance

High density polyethylene hdpe liners possess excellent resistance to thermal oxidation and are environmentally aged due to the implementation of highly efficacious anti-oxidation and anti-aging additives. They remain flexible, maintain tensile strength and have good sealing performance over long periods of time, even when exposed to extreme climatic conditions.

4.3 Long Service Life

With the excellent UV resistance and weather stability qualities, lining hdpe by proper installation and operation can have a life expectancy of 20–30 years or even more. This great feature results in a considerable decrease in maintenance costs and the frequency of replacement for long-term projects.

4.4 Temperature Resistance

HDPE impermeable liner can be relied upon to perform well at temperatures at which most materials become brittle need to be avoided or causing other inconveniences. From here, in an environment where the heat rises to a very high temperature, there is no question of a material becoming softened. This, therefore, is what makes them adaptable to a variety of different climatic conditions.

4.5 Resistance to Environmental Stress

Environmental changes in temperature, moisture, and external loadings can cause environmental stress cracking and this is hardly possible if a material is HDPE. Even if these cracks have the opportunity of developing, the behavior of the material in resisting them will be very good. The practicality of this feature in enhancing durability in both exposed and buried applications is quite evident.

5. High Density Polyethylene HDPE Liners - RFQ Q&A

Q1: What is an High Density Polyethylene HDPE Liners and what is it made for?

A1: An HDPE liner is a high-quality waterproofing membrane made from superior polyethylene resin. It is generally used for waterproofing and containment as well as for environmental protection at ponds, reservoirs, irrigation canals, landfills, mining tailings ponds, and industrial wastewater storage.

Q2: What equipment is used for High Density Polyethylene HDPE Liners installation and welding?

A2: HDPE liners installation involves unfolding the sheets and heat sealing the joining edges using thermal fusion welding (hot wedge or extrusion welding). Proper welding will guarantee strong, leak-proof seams. Professional seam testing should be considered for critical or high-risk projects.

Q3: Are High Density Polyethylene HDPE Liners available in different variations?

A3: Certainly! HDPE liners are available in different thicknesses, widths, lengths, and colors (mostly black). You can even get reinforced ones with scrim for added puncture resistance and mechanical strength.

Q4: How long do HDPE liners normally last?

A4: HDPE liners, if handled well, properly installed, and maintained, can serve 20–30 years or even longer under adverse environmental and chemical conditions.

Q5: What international standards do your High Density Polyethylene HDPE Liners follow?

A5: Our HDPE liners are manufactured in accordance with ASTM, ISO, and GRI (Geomembrane Research Institute) standards which guarantee their performance, dimensional stability, and mechanical strength.

Q6: How to submit quotation request (RFQ) for High Density Polyethylene HDPE Liners?

A6: You can request a quotation by sending your requirements including thickness, roll width, length, quantity, and application to our sales team. We will quickly respond with a competitive offer.

Summary

High Density Polyethylene HDPE Liners by GEOSINCERE Geosynthetics represent a trustworthy, long-lasting, and cost-efficient solution for numerous environmental, industrial, and water management cases. With excellent impermeability, chemical resistance, UV stability, and extended service life, Shandong Geosino New Material Co., Ltd.(GEOSINCERE Geosynthetics)high density polyethylene hdpe liners secure efficient containment and protection at ponds, reservoirs, landfills, mining sites, and wastewater treatment plants. Supported by a rigorous quality control system and tailored specifications, GEOSINCERE Geosynthetics HDPE liners offer a reliable resource to engineers and project managers for contemporary containment and waterproofing requirements.