What is Geomembrana HDPE 40 Mils?

Introduction: Understanding Geomembrana HDPE 40 Mils

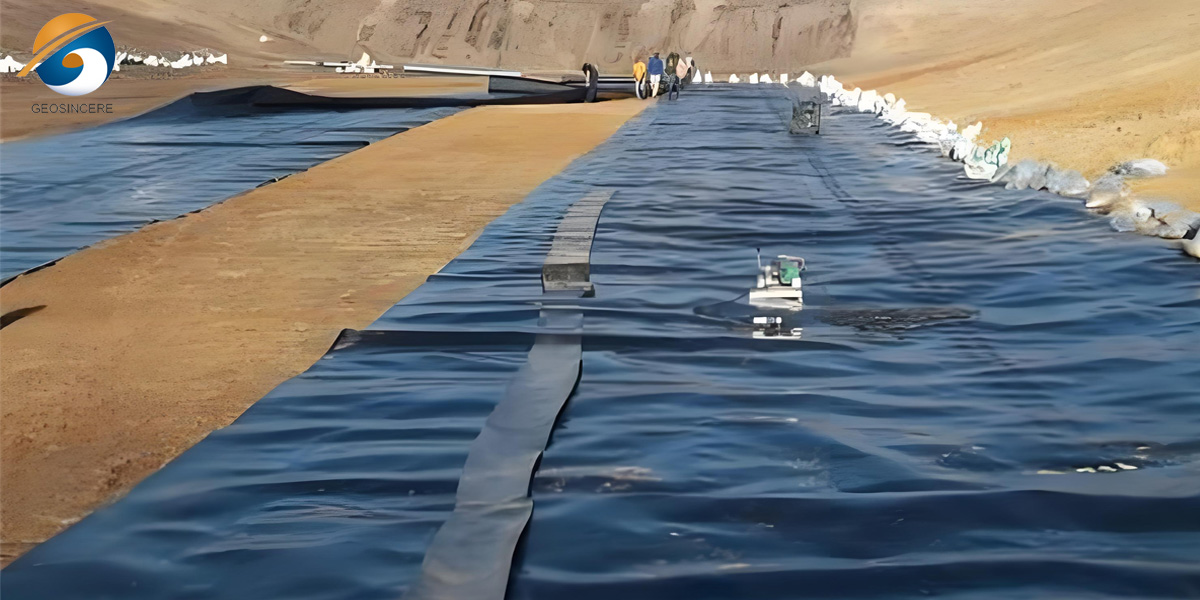

In modern civil engineering, mining, and environmental protection projects, waterproofing and containment systems play a crucial role in ensuring structural integrity and environmental safety. Among various geomembrane materials, HDPE (High-Density Polyethylene) geomembrana has become one of the most widely used synthetic liners in the world.

This article aims to give you a complete understanding of what an HDPE geomembrane 40 mils is — including its definition, specifications, applications, installation guidance, and technical advantages — so you can confidently choose the right geomembrane for your project.

2. What Does “Geomembrana HDPE 40 Mils” Mean?

The term “HDPE geomembrane 40 mils” refers to a high-density polyethylene membrane liner with a nominal thickness of 40 mils, which equals approximately 1.0 mm (since 1 mil = 0.0254 mm).

This membrane is designed to provide impermeability, chemical resistance, and UV protection for various applications such as ponds, landfills, canals, reservoirs, and mining leach pads.

Here’s a quick conversion reference for HDPE geomembrane thickness:

Thickness (mils) | Thickness (mm) | Typical Use |

20 mils | 0.5 mm | Small ponds, secondary liners |

30 mils | 0.75 mm | Water containment, decorative ponds |

40 mils | 1.0 mm | Industrial ponds, landfill capping |

60 mils | 1.5 mm | Wastewater treatment, mining ponds |

80–100 mils | 2.0–2.5 mm | Hazardous waste containment, oil & gas |

So, HDPE geomembrana 40 mils = 1.0 mm thick waterproof liner, ideal for medium-scale waterproofing and containment projects where flexibility and durability are both important.

3. Advantages of Using Geomembrana HDPE 40 Mils

3.1 Excellent Impermeability

HDPE liner has one of the lowest permeability coefficients among all polymeric liners, ensuring no leakage or seepage through the membrane.

3.2 Outstanding Chemical Resistance

It resists acids, alkalis, salts, and many industrial chemicals, which makes it ideal for landfills, chemical ponds, and industrial wastewater treatment plants.

3.3 UV and Weather Resistance

Thanks to the high carbon black content (usually 2–3%), HDPE geomembrane liner performs well under intense sunlight and outdoor exposure, maintaining flexibility and strength for years.

3.4 High Tensile Strength and Flexibility

Although HDPE is a stiff material compared to LLDPE, 40 mils thickness strikes a balance between flexibility and strength, making it easier to install while maintaining durability.

3.5 Long Lifespan

Under normal exposure, geomembrane sheet can last over 20 years. When buried or covered, service life can exceed 50 years.

3.6 Cost-Effective

Compared with thicker liners like 60 or 80 mils, 40 mils HDPE provides sufficient protection at a lower cost, suitable for projects that do not require heavy-duty containment.

4. Common Applications of Geomembrana HDPE 40 Mils

4.1 Geomembrana HDPE 40 Mils for Pond and Canal Lining

HDPE 40 mils is widely used for fish ponds, irrigation canals, and decorative ponds, providing an impermeable barrier that prevents water loss and soil contamination.

4.2 Geomembrana HDPE 40 Mils for Landfill Cover Systems

For landfill closure or capping layers, 40 mils HDPE can act as a surface sealing membrane, preventing rainwater infiltration and gas emission.

4.3 Geomembrana HDPE 40 Mils for Mining and Leachate Containment

In mining operations, 40 mils liner is used for solution ponds and secondary containment, offering chemical resistance to acidic leachates.

4.4 Geomembrana HDPE 40 Mils for Wastewater Treatment Plants

HDPE geomembrana prevents wastewater from seeping into the ground, maintaining clean soil and groundwater conditions.

4.5 Geomembrana HDPE 40 Mils for Agriculture and Aquaculture Projects

Used in shrimp ponds, biogas digesters, and silage pits, HDPE geomembrane ensures containment efficiency and hygiene control.

4.6 Geomembrana HDPE 40 Mils for Secondary Containment and Waterproofing

Ideal for industrial containment basins, tank farms, and secondary spill containment, where a reliable waterproof layer is needed.

5. Installation Considerations for Geomembrana HDPE 40 Mils

Proper installation is critical to ensure the performance and lifespan of the geomembrane.

5.1 Subgrade Preparation

Ensure a smooth, compacted, and clean subgrade.

Remove sharp stones, roots, and debris to prevent puncturing the liner.

5.2 Unrolling and Placement

Use lifting equipment to avoid damaging the rolls.

Overlap adjacent sheets by at least 100 mm (4 inches).

5.3 Seaming Process

The most common seaming methods include:

Hot wedge welding

Hot air welding

Extrusion welding (for details and corners)

GEOSINCERE Geosynthetics provides professional welding machines and training for local installation teams to ensure secure seams that pass vacuum and destructive tests.

5.4 Quality Inspection

Each weld should be tested using:

Air pressure test

Vacuum box test

Visual inspection

Quality assurance is essential to guarantee long-term performance.

6. How to Choose the Right Thickness: Why 40 Mils?

Choosing the right geomembrane thickness depends on the type of project, loading conditions, and expected lifetime.

Application | Recommended Thickness |

Garden pond / Landscape | 0.5 – 1.0 mm (20–40 mils) |

Irrigation canal | 1.0 mm (40 mils) |

1.0 – 1.5 mm (40–60 mils) | |

Wastewater pond | 1.5 mm (60 mils) |

Mining / Leach pad | 1.5 – 2.0 mm (60–80 mils) |

Therefore, HDPE geomembrane 40 mils is an excellent mid-range choice — thick enough for durability, yet economical for large-scale projects.

7. GEOSINCERE Geosynthetics Quality Control and Certification

As a professional geosynthetics manufacturer and exporter, GEOSINCERE Geosynthetics ensures strict quality control from raw material selection to final inspection.

7.1 Production Process

Raw material testing

Film extrusion using automatic blown film lines

Online thickness monitoring

Winding and packaging under clean environment

7.2 Quality Standards

GEOSINO’s HDPE geomembranes comply with international standards:

ASTM D5199 / D638 / D6693

GB/T 17643-2011

GRI GM13

7.3 Certificates

ISO 9001:2015 Quality Management System

CE certification for export

SGS and BV test reports available

7.4 Packaging and Delivery

Standard roll width: 7m or custom

Roll length: 50m or 100m

Export-ready packaging with protective film

Fast delivery via Guangzhou or Shenzhen ports

8. GEOSINCERE Geosynthetics’s Competitive Advantages

8.1 Factory-Direct Manufacturing

At GEOSINCERE Geosynthetics, we manage the entire production process — from virgin HDPE resin selection to film extrusion, welding, and packaging.

This vertical integration allows us to deliver consistent quality, shorter lead times, and factory-direct pricing without middlemen, giving our clients the best value possible.

8.2 Proven Global Export Experience

With over a decade of export experience, GEOSINCERE Geosynthetics has successfully delivered HDPE geomembranes to more than 90 countries worldwide, including:

South Korea, the Philippines, Chile, Kenya, Saudi Arabia, and Australia.

Our products are trusted by engineers, contractors, and distributors across Asia, the Middle East, Africa, and Latin America for their reliability and performance in diverse climates and soil conditions.

8.3 Professional Technical Support

GEOSINCERE Geosynthetics doesn’t just sell geomembranes — we provide complete technical solutions.

Our experienced engineers offer:

Project design recommendations

Installation and welding guidance

On-site or remote technical assistance

We ensure every client can install and maintain our geomembranes with confidence and precision.

8.4 Flexible Customization Options

Every project is different. That’s why GEOSINO offers custom manufacturing based on your specific needs:

Thickness: from 0.2 mm to 3.0 mm

Width: up to 8 meters per roll

Roll length and weight according to project scale

Colors available: black, blue, or green

Whether you’re lining a small pond or a large landfill, we can tailor our HDPE geomembrane to fit perfectly.

8.5 Reliable After-Sales Service

Our service doesn’t stop after shipment. GEOSINCERE Geosynthetics’s dedicated support team follows up to ensure:

Smooth customs clearance and delivery

Correct installation on-site

Long-term satisfaction with performance and durability

We believe in building long-term partnerships, not just one-time sales. Your success is our mission.

9. Conclusion: Why Choose GEOSINCERE Geosynthetics Geomembrana HDPE 40 Mils

The HDPE geomembrana 40 mils is a versatile and durable waterproofing material suitable for a wide range of civil, environmental, and agricultural projects. It combines excellent impermeability, UV stability, and chemical resistance with a cost-effective price point.

At GEOSINCERE Geosynthetics, we are committed to providing not only premium-quality geomembranes but also complete project solutions, from technical consultation to on-site guidance.

If you are looking for a reliable HDPE geomembrane 40 mils supplier, contact us today.