What is a Reinforced Geomembrane and Why You Need It for Your Project?

In the world of civil engineering, environmental protection, and large-scale construction, there exists a type of substances that work tirelessly out of sight. They are the unsung heroes maintaining returned contamination, stabilizing earth, and keeping our water resources. Among these, one product stands out for its special aggregate of impermeability and brute strength: the reinforced geomembrane.

If your venture entails controlling liquids, containing waste, or stopping seepage, perception this reinforced polypropylene geomembrane material is no longer simply an advantage—it's a necessity. This complete information will demystify what a reinforced geomembrane is, how it works, and crucially, why it would possibly be the quintessential element your mission has been missing.

1. The "What": Deconstructing the Reinforced Geomembrane

Let's damage down the title to recognize its essence.

A geo membranes are in reality a very low-permeability artificial sheet or liner. Think of it as a massive, pretty long lasting tarp, however its foremost job is not to maintain rain out; it is to preserve liquids in or out of a precise area. Made from polymers like High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), or Linear Low-Density Polyethylene (LLDPE), hdpe liner is the go-to answer for growing impermeable barriers.

So, what does "reinforced" mean in this context? It’s all about tensile strength.

A standard, non-reinforced hdpe geomembrane depends totally on the thickness of the polymer sheet for its strength. While bendy and effective, it can be inclined to punctures, tearing, and stress cracking below heavy masses or sharp substrates.

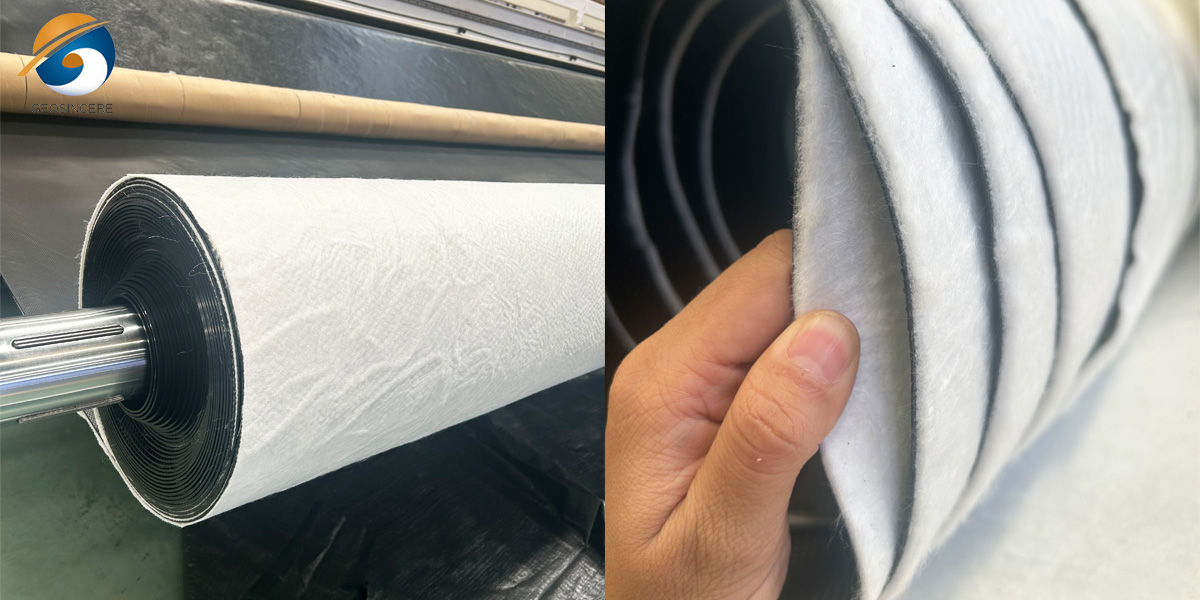

A reinforced geomembrane liner comprises a strengthening core inside the polymer layers. This core is usually a grid or scrim made from:

- High-Tenacity Polyester (PET) Yarn: Known for its exceptional tensile electricity and resistance to elongation.

- Fiberglass: Offering excessive tensile energy at a noticeably low cost.

This core is laminated between two or extra layers of the polymer, growing a composite cloth that inherits the fantastic houses of each components: the impermeability and chemical resistance of the polymer, and the tremendous tensile and puncture resistance of the reinforcing scrim.

The result? A geomembrane sheet that is no longer simply a barrier, however a structurally robust, load-bearing factor of your project.

The "How": The Manufacturing Process and Key Properties

The manufacturing process, commonly thru lamination or co-extrusion, ensures a robust bond between the polymer and the reinforcement. This fusion is what offers reinforced geomembranes their standout characteristics:

1.1 Exceptional Tensile Strength

This is the most important advantage. The reinforcing scrim includes the tensile loads, permitting the hdpe membrane to stand up to substantial stress barring stretching or failing. This is measured in each desktop and cross-machine directions.

1.2 High Puncture and Tear Resistance

The grid shape distributes factor masses (like a sharp rock) over a wider area, substantially lowering the danger of puncture. Tear propagation is additionally successfully halted by means of the scrim.

1.3 Dimensional Stability

Unlike some non-reinforced high density polyethylene geomembrane that can stretch beneath warmness or load, strengthened sorts have very low elongation, which means they keep their structure and integrity beneath a vast vary of temperatures and stresses.

1.4 Robust Seam Strength

The seams, created by using strategies like fusion welding (for HDPE) or chemical welding (for PVC), are especially robust due to the fact the reinforcement provides balance for the duration of the seaming process, developing a joint that is almost as sturdy as the sheet itself.

1.5 Retained Chemical Resistance

The polymer exterior nevertheless affords wonderful resistance to a extensive vary of chemicals, acids, alkalis, and UV radiation, relying on the base resin chosen.

2. The "Why": 5 Compelling Reasons You Need Reinforced Geomembrane for Your Project

Now for the vital part. When does a trendy geo membrane sheet suffice, and when need to you specify a reinforced one? Here are the situations the place selecting a reinforced geomembrana in hdpe is now not simply a precise idea, however a critical requirement for the project's success and longevity.

2.1 When Your Project Involves High Loads or Steep Slopes

This is the most frequent application. Imagine a big heap of mining waste (tailings), a landfill with heaps of heaps of trash, or a reservoir lining on a steep embankment. The gravitational forces at play are immense.

A non-reinforced hdpe geo membrane should slowly stretch and deform underneath this consistent pressure, doubtlessly main to failure.

A reinforced hdpe geomembrane liner acts like a tensile skin, preserving the cloth in place. It resists the downward and outward forces, keeping the system's structural integrity. For tasks like capping landfills or lining steep containment ponds, this is non-negotiable.

2.2 When You Face Challenging Subgrades or Aggressive Materials

Not each and every undertaking web site is a smooth, sand-lined bed. Often, the subsoil can be rocky, uneven, or incorporate debris.

A trendy hdpe geomembrane sheet positioned at once on a hard subgrade is a puncture ready to show up at some stage in set up or from long-term settlement.

The reinforced pvc geomembrane's superior puncture resistance acts as an insurance plan policy. It can bridge small voids and face up to the stress from sharp protrusions, making sure the impermeable barrier stays intact for decades. This is imperative in mining operations and construction dewatering ponds where the substrate is hardly ever ideal.

2.3 When Long-Term Reliability is Paramount (And Costly Failures are Not an Option)

The penalties of a lldpe geomembrane failure can be catastrophic: environmental contamination, big remediation costs, venture shutdowns, and felony liabilities.

Reinforcement provides a imperative security factor. It enhances the material's resistance to stress cracking, a phenomenon the place a small flaw can propagate into a giant tear over time.

By specifying a reinforced hdpe liner sheet, you are investing in long-term chance mitigation. For primary containment of hazardous liquids or potable water reservoirs, this delivered protection is really worth each and every penny. It’s the distinction between a barrier that is surely "present" and one that is "engineered to perform."

2.4 When You Need a Robust Liner That Can Withstand Installation Stresses

Installation is a high-risk phase. Workers on foot on the liner, tools movement, and the universal managing of heavy rolls can compromise a weaker material.

Reinforced membrane liners are inherently more difficult and greater forgiving at some stage in installation. Their excessive tear resistance ability that a small snag is much less in all likelihood to flip into a principal rip, saving time and cash on repairs.

This sturdiness frequently permits for the use of a much less ideal (and much less expensive) subgrade preparation, as the liner can cope with extra abuse.

2.5 For Applications Requiring a Structural Component

In some progressive applications, the reinforced impermeable geomembrane isn't always simply a liner; it is phase of the shape itself. Think of floating covers on tanks or reservoirs that should face up to wind, wave action, and the weight of gathered rainwater or snow. The tensile electricity of the strengthened impermeable geomembrane liner is what continues the cowl taut, stable, and functional.

3. Choosing the Right Type: HDPE vs. PVC Reinforced Geomembrane

The base polymer matters. The two most frequent hdpe dam liners are:

3.1 Reinforced HDPE (R-HDPE) Geomembrane

Offers most suitable chemical resistance, UV stability, and a very excessive tensile strength. It is stiff and requires expert seaming. Ideal for harsh environments like landfills, mining, and chemical containment.

3.2 Reinforced PVC (R-PVC) Geomembrane

More bendy and conformable, making it extraordinary for complicated shapes and uneven subgrades. It is simpler to seam in the field. Often favored for water canals, ornamental ponds, and landfill caps the place flexibility is key.

Your desire will rely on the chemical exposure, website geometry, set up conditions, and venture budget.

4. Reinforced Geomembrane Installation and Construction Considerations

While reinforced geomembrane is inherently extra robust, their set up needs the equal degree of expert understanding as any different geosynthetic. Proper subgrade guidance stays paramount; even the hardest liner can't function optimally over a bed of sharp, unstable debris. The subgrade must be smooth, compacted, and free of protrusions that may want to purpose "point loading" over time. Seaming is every other crucial phase. For R-HDPE, this commonly entails dual-track warm wedge welding to create a continuous, high-strength seal, with each and every inch of the seam examined for integrity, frequently with air strain or vacuum testing. R-PVC seams, regularly created with chemical solvents or warm air welders, ought to additionally be meticulously achieved to shape a monolithic barrier. This emphasis on high-quality assurance at some point of set up is what transforms the uncooked material's practicable into a guaranteed, long-lasting performance.

5. Conclusion

A reinforced Geomembrane is extra than simply a "stronger liner." It is a high-performance engineering cloth designed to remedy the most disturbing containment challenges. While its preliminary price may also be greater than a non-reinforced alternative, this is a traditional case the place the actual price is measured in decreased risk, long-term performance, and closing mission success.

Before you finalize the specs for your subsequent containment project, ask yourself: Can I have enough money a failure? If the reply is no, then the query isn't whether you want a geomembrane, but why you would not pick out a bolstered one. It is the definitive desire for making sure your barrier is constructed now not simply to last, however to function beneath pressure.

Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) is specialised in all sorts of HDPE/LDPE/LLDPE Geomembrane , Geotextile,Geogrid, GCL and different geosynthetics. Which has 36000 rectangular meters manufacturing manufacturing unit with ISO9001.ISO 4001,CE,SASO,GAI LAP,Soncap and BV certification and handed the check of SGS and Intertek etc, We are willing to turn out to be your dependable accomplice to construct the future of sustainable civil engineering projects.Kindly contact us for greater records or solutions.