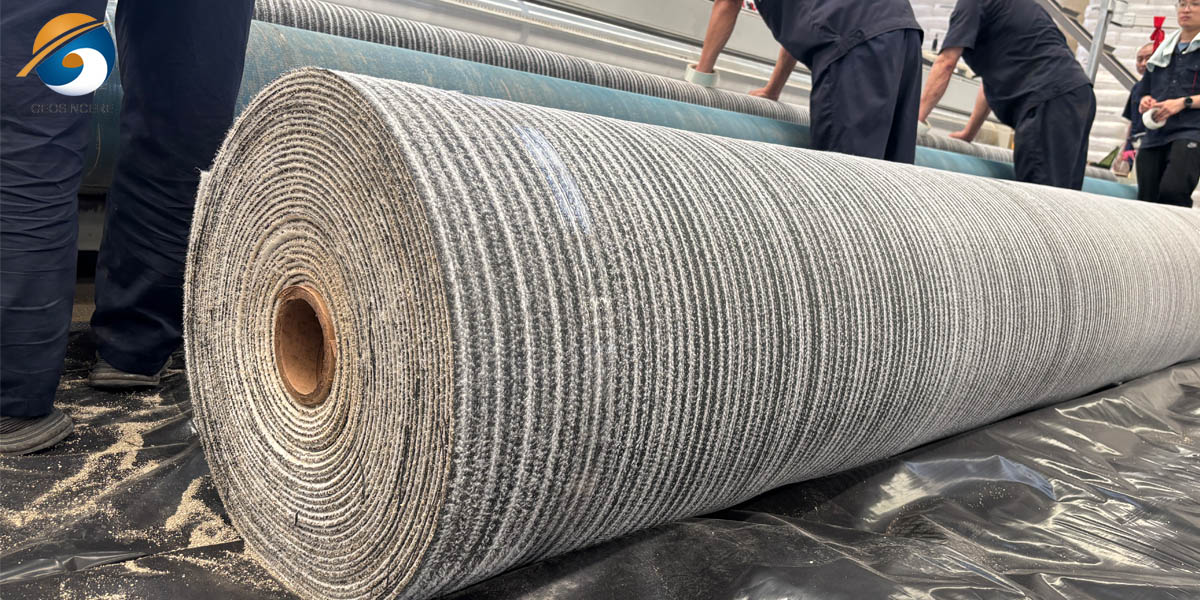

Clay Liner in Landfill

Clay liner is essential components in modern landfill engineering, providing an effective barrier to prevent leachate from contaminating soil and groundwater. Made from compacted natural clay with low permeability, these geosynthetic clay liner ensure long-term environmental protection and regulatory compliance.

- High Impermeability: Effectively limits the movement of liquids, protecting surrounding soil and water resources.

- Durable and Long-Lasting: Resistant to settlement and chemical reactions, ensuring a stable containment layer.

- Environmentally Friendly: Natural material with minimal environmental impact, supporting sustainable landfill design.

- Customizable Thickness & Size: Adaptable to different landfill sizes and project requirements.

- Cost-Effective Solution: Combines efficiency with durability, reducing long-term maintenance costs.

GCL liner serve as a crucial part of landfill systems, often used in combination with geomembranes for enhanced protection.

Clay liner in landfill is a critical component in modern landfill engineering, providing a reliable barrier to prevent contamination of soil and groundwater. Made from natural, highly compacted clay, it offers exceptional impermeability, durability, and environmental protection. Our bentonite clay liner is designed to meet strict regulatory standards, ensuring safe waste containment for both municipal and industrial landfills. In addition, they maintain long-term performance even under high pressure and varying environmental conditions. This makes them a trusted, cost-effective solution for sustainable landfill construction and long-term environmental security.

1. Clay Liner in Landfill Key Features

1.1 High Impermeability

Our clay liner have a low hydraulic conductivity (typically <1×10⁻⁷ cm/s), effectively preventing leachate from seeping into surrounding soil and groundwater.

Ideal for landfills, mining tailings, and industrial waste containment projects.

The fine-grained structure of the clay particles creates a dense, compact matrix that blocks the movement of liquids.

Even under fluctuating moisture conditions, the gcl pond liner maintains its impermeable properties, ensuring consistent protection throughout the landfill’s service life.

1.2 Durable and Long-Lasting

Resistant to natural weathering, compression, and settlement.

Maintains integrity under heavy loads and over extended periods, ensuring a reliable long-term solution.

The bentomat geosynthetic clay liner material adapts to ground movements without cracking, making it suitable for sites with differential settlement.

Its long-term durability reduces the need for frequent replacements, lowering maintenance costs for landfill operators.

1.3 Environmentally Safe

Made from natural, non-toxic clay materials.

Provides a sustainable solution by minimizing environmental contamination and protecting local ecosystems.

Because the clay is sourced from natural deposits, it has no harmful chemical ingredients and poses zero risk to water or soil quality.

Its natural composition makes it compatible with eco-friendly landfill designs focused on long-term environmental stewardship.

1.4 Customizable Thickness and Compaction

Available in various thicknesses depending on project requirements, typically ranging from 300mm to 600mm or more.

Compaction standards can be tailored to meet local regulatory guidelines or specific landfill designs.

Engineers can adjust moisture content and compaction energy to achieve the exact permeability and strength required for the project.

This flexibility allows the bentomat clay liner to perform effectively across diverse climates, soil types, and waste load conditions.

1.5 Easy Integration with Other Liners

Can be combined with geomembranes or geosynthetic clay liners (GCL) for double-layer protection.

Supports composite liner systems for enhanced safety in high-risk landfills.

The clay layer forms a stable foundation for geomembranes, reducing the risk of punctures and enhancing the performance of the entire system.

When used as part of a multilayer barrier, the geo clay liner significantly improves overall containment efficiency and long-term leakage control.

2. Clay Liner in Landfill Applications

2.1 Municipal Solid Waste Landfills

Ensures safe containment of household and commercial waste.

The geocomposite clay liner prevents leachate from migrating into surrounding soil, protecting groundwater sources used by nearby communities.

Its long-term stability makes it a dependable solution for municipal landfill cells that require decades of environmental protection.

2.2 Industrial Landfills

Ideal for hazardous and non-hazardous industrial waste.

The clay’s low permeability helps isolate industrial chemicals, oils, and byproducts that pose higher environmental risks.

It works effectively with composite liner systems to meet strict regulatory requirements for industrial waste disposal.

2.3 Mining and Tailings Storage Facilities

Provides a protective barrier to prevent heavy metal and chemical contamination.

The bentonite geosynthetic clay liner withstands high loads from tailings material, ensuring structural stability over large containment areas.

Its resistance to chemical attack makes it suitable for mining operations involving acidic or metal-rich waste streams.

2.4 Leachate Ponds and Wastewater Containment

Suitable for ponds requiring impermeable layers.

The clay liner landfill layer prevents seepage from storage ponds, ensuring controlled and safe management of contaminated liquids.

Its natural sealing capability enhances operational reliability in wastewater treatment facilities and landfill leachate collection systems.

3. Clay Liner in Landfill Customer Benefits

3.1 Compliance with Environmental Regulations

Helps meet international and local landfill standards, reducing legal and environmental risks.

The clay liner in landfill’s proven impermeability and stability ensure it aligns with the strict requirements of environmental protection agencies.

Using a compliant liner system also streamlines project approval processes, saving time and reducing administrative challenges for landfill operators.

3.2 Cost-Effective Solution

Natural clay liners are often more economical than synthetic liners, especially for large-scale landfills.

Their availability in many regions reduces transportation costs and simplifies sourcing for large construction projects.

Additionally, the long service life of gcl clay liner minimizes future repair expenses, further enhancing overall cost efficiency.

3.3 Peace of Mind

Offers long-term reliability, reducing the need for frequent maintenance or repairs.

The stable performance of clay under varying environmental conditions ensures consistent protection throughout the landfill’s operational lifespan.

Its natural resistance to cracking and deterioration provides confidence for engineers and project owners managing high-value containment sites.

3.4 Versatile Design Options

Can be adapted to specific project needs, soil conditions, and engineering specifications.

Engineers can customize liner thickness, compaction levels, and installation methods to match diverse project requirements.

This adaptability allows gcl geosynthetic clay liners to perform effectively in challenging terrains, climates, and waste-loading conditions.

4. Clay Liner in Landfill Quality Control & Testing Standards

4.1 Laboratory Testing (ASTM, ISO, GRI Standards)

Our geotextile clay liner is tested in accredited laboratories following ASTM, ISO, and GRI standards. These tests verify key properties such as permeability, plasticity, and strength to ensure consistent product performance. Standardized testing methods guarantee reliable data and full compliance with landfill engineering requirements.

4.2 Permeability and Compaction Tests

We conduct permeability tests to confirm the geosynthetic clay liner meets required low hydraulic conductivity levels. Compaction tests ensure the material can achieve the specified density during installation. Together, these evaluations confirm the liner’s long-term ability to resist seepage and withstand waste loads.

4.3 On-Site Inspection Procedures

During installation, on-site inspections monitor moisture content, compaction density, and layer thickness. Any deviations are corrected immediately to maintain quality and prevent defects. This process ensures the installed liner performs as designed and achieves its targeted impermeability.

4.4 Third-Party Certifications

Independent third-party certifications further validate the geosynthetic clay liner’s quality and compliance. These assessments provide unbiased confirmation that the product meets regulatory and industry standards. This added verification enhances trust and reliability for critical landfill projects.

5. Clay Liner in Landfill Customization Options

5.1 Adjustable Liner Thickness

We offer geo clay liner in various thickness options to match different landfill design requirements. Engineers can select the ideal thickness based on waste load, environmental risk level, and regulatory standards.

This flexibility ensures optimal containment performance across municipal, industrial, and mining projects.

5.2 Compaction and Density Customization

Compaction levels can be adjusted to achieve the specific density required for each project. Customized compaction improves impermeability and structural stability under long-term waste loads.

It also allows the liner to meet strict engineering specifications set by local authorities or design consultants.

5.3 Tailored Moisture Conditioning

Moisture content can be modified to ensure proper workability and optimal compaction during installation. Controlled moisture levels help achieve the target hydraulic conductivity and prevent cracking.

This customization ensures the clay performs consistently in different climates and soil conditions.

5.4 Supply in Bulk or Per Project Plan

We can supply geocomposite clay liner in bulk quantities or according to a specific project schedule. Flexible delivery options help contractors manage site logistics and reduce material storage time.

This approach ensures that each phase of the landfill construction receives material exactly when needed, improving efficiency.

6. Clay Liner in Landfill Packaging & Delivery Details

6.1 Transport Form (Bulk Delivery, Compacted Blocks, Processed Bags)

Our clay liners can be delivered in bulk, compacted blocks, or pre-processed bags depending on project needs. This flexibility allows efficient transportation and reduces handling costs on-site.

Each form is designed to protect the material during transit, minimizing damage and maintaining quality until installation.

6.2 On-Site Handling Guidelines

Proper handling on-site is essential to preserve the liner’s integrity and performance. We provide clear instructions for unloading, placement, and layer preparation to avoid contamination or damage.

Following these guidelines ensures the clay liner retains its impermeability and structural properties throughout installation.

6.3 Storage Moisture Control

Clay liners must be stored with proper moisture control to prevent drying or excessive wetting before use. We recommend covered storage in a shaded, well-drained area to maintain optimal moisture content.

This precaution helps preserve workability and ensures consistent compaction and performance during installation.

7. Clay Liner in Landfill – Frequently Asked Questions (FAQ)

Q1: What is the required thickness for a clay liner in a landfill?

A: The required thickness typically ranges from 0.6 to 1.0 meters (24–40 inches), depending on the type of waste, local regulations, and site conditions. Thicker liners are often recommended for high-leachate or industrial waste landfills to ensure maximum impermeability.

Q2: What is the expected service life of a clay liner?

A: When properly installed and maintained, a clay liner can last 20 to 50 years or more. Its durability depends on soil compaction, environmental factors, and avoidance of mechanical damage or chemical degradation.

Q3: What are the maintenance requirements for a clay liner?

A:Regular inspections: Check for cracks, erosion, or settlement.

Surface protection: Cover with a protective layer (e.g., soil or geomembrane) to prevent desiccation or physical damage.

Prompt repair: Any damage should be repaired immediately using compatible clay material and proper compaction techniques.

Q4: Is the clay liner compatible with other materials?

A: Yes, clay liners can be used in combination with:

Geomembranes: Forming a composite liner system for enhanced impermeability.

Geotextiles: Used as a protective or separation layer.

Drainage layers: Placed above the clay liner to manage leachate collection.

Compatibility should always be verified based on chemical exposure and project design.

Summary

Our Clay Liner in Landfill offers high impermeability, long-lasting durability, and reliable performance for safe waste containment. Engineered to meet strict environmental standards, it ensures effective groundwater protection and minimal maintenance over its service life. For projects that demand quality and trust, choose Shandong Geosino New Material Co., Ltd.(GEOSINCERE Geosynthetics)for dependable clay liner solutions.