What is Polyethylene Geomembrane and How Does it Work?

In our current era where the focus is on reducing our environmental impact and building resilient infrastructures, engineered materials are often the ones silently saving the day, without even us realizing it. They help protect our water, land, and other resources in various ways. Polyethylene geomembrane is one such hero - a synthetic liner that has become an essential element of environmental and geotechnical engineering. However, what is that exactly and more importantly, how does it work? This article discusses the composition, manufacturing, and operating principles of polyethylene geomembranes, thus, helping us understand the reasons behind their global popularity as a containment material.

1. Polyethylene Geomembrane: A Short Introduction

In the most basic terms, a geomembrane is a polymer sheet that is impermeable to gases and liquids and hence, acting as a barrier that controls the migration of fluids or vapors in a system, a structure, or a project. "Polyethylene" in the term tells us the type of plastic that the sheet is made from. Among different types of plastics, polyethylene (PE) is the most used one all over the world. You can find the same material in plastic grocery bags and shampoo bottles. Nonetheless, hdpe membrane is totally different from such everyday articles. They are specially designed and produced to be highly resistant to wear and overdurable to environmental conditions.

A hdpe geomembrane is essentially a high-grade planar product fabricated from polyethylene resin and typically having a thickness from 0.5 mm to 3.0 mm (20 to 120 mils). Its main job is to act as a barrier that a liquid or gas can't penetrate for a very long time. It may be somewhat flexible and able to take quite some stretch, but hdpe liners certainly doesn't provide any structural strength here. Thus, it works as a continuous lining system that restrains the flow of liquids and gases.

2. The Polyethylene Geomembrane Raw Material: Types of Polyethylene Used

To be honest, not every polyethylene is suitable for making a high density polyethylene geomembrane. Some particular variants would be good depending on their density and molecular structure or the extent of branching of the polymers that they contain.

2.1 High-Density Polyethylene (HDPE)

This is the most popular and the most often used material in hdpe geo membrane production. HDPE has a molecular chain with very few branches at all, so it is heavier and very crystalline. Hence, it has outstanding chemical resistance, good tensile strength, and, most of all, very good durability against ultraviolet (UV) rays. HDPE geomembrane liner is basically the primary material for the lining of landfills, mining heap leach pads, and reservoir capping for very long periods of time since it keeps the properties even in harsh environments for a long time.

2.2 Linear Low-Density Polyethylene (LLDPE)

LLDPE has short branches that are uncontrollable gently attached to the linear backbone. This makes the structure relatively more flexible and able to be elongated when compared to HDPE. LLDPE geomembrane is quite conformable and therefore, it can properly work even if there is differential settlement. Besides, it has an excellent resistance to punctures. That is why it is mostly used in the decorative pond, landfill cover, and canal lining projects where both flexibility and resistance to cracking from stress are required.

2.3 Very Low-Density Polyethylene (VLDPE)

VLDPE is capable of providing even more flexibility and elongation than LLDPE. It is mostly used in the manufacture of multi-layer co-extruded geomembranes where extreme conformability is one of the main requirements.

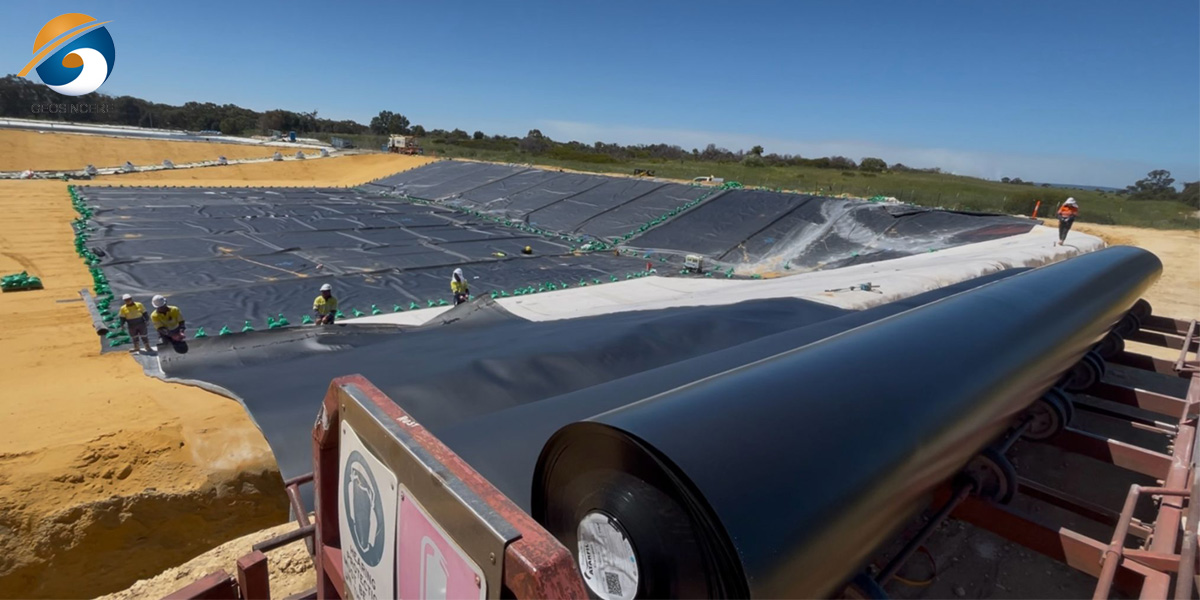

3. Manufacturing: From Resin to Robust Polyethylene Geomembrane

Polyethylene pellets go through an elaborate industrial process to emerge as a uniform and sturdy geomembrane sheet. The two main technologies used are:

3.1 Flat Die Extrusion (also called Sheet Extrusion)

The molten polyethylene is pushed by a screw through a die that forms the sheet. The extrusion is then passed through the cooling rollers or water bath to get solidified.

Such a system offers the possibility of producing either smooth or textured surfaces.

3.2 Blown Film Extrusion

By far, the majority of HDPE and many LLDPE geomembranes are manufactured using this technique. Firstly, molten polyethylene is forced out through a circular die forming a continuous tube. This tube is then inflated with air (like a huge balloon), which stretches it radially while being pulled up, thus stretching it lengthwise. The polymer molecules are thus oriented in two directions which bring about a significant increase in the tensile strength and stress crack resistance of the geomembrane. Next, the inflated tube is flattened and folded. Texturing can be introduced at this stage by using specially designed cooling rollers.

The process of texturing - making a surface rough - is an important path breaking feature. A textured layer can be added by co-extrusion or a polymer spray can be applied during cooling. The interface friction (shear strength) between hdpe impermeable liner and soils or geosynthetics is hugely increased due to texturing, which results in greater stability of slopes.

4. How Does Polyethylene Geomembrane Work? The Principles of Barrier Performance

A polyethylene geomembrane is not a magic trick, rather it works due to the physical and chemical characteristics of the material. There’re a few key principles behind its functioning:

4.1 Impermeability and Resistance to Diffusion:

Being a barrier is their most crucial function. To put it simply, polyethylene is a solid, water-repellent polymer. It is soil that has interconnected pores whereas a high-quality geomembrane doesn't have any pores. Its impermeability is measured by its water vapor transmission rate, which is one of the lowest. It basically gives a continual, monolithic physical barrier to the substance. The liquid cannot permeate it because there are no channels. Contaminants that are dissolved (e.g. heavy metals or salts) cannot move by advection (bulk flow). Even air and vapor molecules have a hard time penetrating the dense polymer at a very slow, calculable rate which is important for landfill gas systems.

4.2 Chemical Resistance and Compatibility:

Here is where polyethylene, mainly HDPE, exhibits a great performance. Its long-chain saturated hydrocarbon structure is non-polar and inert. And so membrane hdpe resists almost all chemicals as well as the industrial acids, alkalis, and salt waste present in mining and agriculture. Before starting any project, a chemical compatibility test is done to determine whether the geomembrane will deteriorate, swell, or become weaker after long-term contact with the fluids inside. This is the way how it "works" to separate a highly toxic leachate from the groundwater for a very long time.

4.3 Mechanical Integrity Under Stress:

If the barrier gets torn, punctured, or stretched to the point of failure, it’s of no use. Polyethylene geomembranes essentially work on the basis of having balanced mechanical properties:

4.3.1 Tensile Strength and Elongation

They are capable of holding up to the stretching forces arising from uneven settling or installation. HDPE is characterized by high strength and moderate elongation whereas LLDPE has less strength but a much higher elongation which makes it possible for the material to "give" rather than break.

4.3.2 Puncture and Tear Resistance

The hdpe smooth geomembrane should be capable of withstanding the damage which can come from sharp rocks or debris of the subgrade. This depends on the polymer type, its thickness, and whether protective geotextiles are used. It behaves like a protective cover, spreading the point loads.

4.3.3 Stress Crack Resistance (SCR)

This is critical for HDPE. Stress cracking is a brittle, delayed failure under tension in a chemical environment. Modern, resin-grade HDPE with high SCR is engineered to resist this, ensuring long-term integrity even in challenging, constrained installations.

4.4 Environmental Durability:

A geomembrane must work for 20, 50, or even 100+ years. It achieves this through:

4.4.1 UV Stabilization

Carbon black (typically 2-3%) is added to the resin, acting as a powerful UV absorber and antioxidant, protecting the polymer chains from photo-oxidative degradation by sunlight.

4.4.2 Thermal Stability

Polyethylene has a wide service temperature range. It remains flexible in cold climates and retains strength in hot climates. Its high thermal expansion coefficient is managed through proper design (allowing for wrinkles) and anchoring.

4.4.3 Biological Inertness

It is not a food source for microbes, fungi, or roots, preventing biodegradation.

4.5 The System Approach: Seaming and Integration

A geomembrane liner works as a system, not just as individual rolls. The most critical element is the field seam. Panels are joined in the field using thermal fusion methods:

4.5.1 Dual Hot Wedge Seaming

A hot wedge melts two overlapped sheets, which are then immediately pressed together by rollers, creating two parallel seams with an air channel for non-destructive testing.

4.5.2 Extrusion Seaming

A ribbon of molten PE is extruded over the edge or between two overlapped sheets, bonding them.

A properly executed seam is as strong and impermeable as the parent sheet, creating a continuous, monolithic barrier. The high density polyethylene hdpe liners also works in concert with other geosynthetics (like geotextile cushion layers, drainage geonets, and geogrids) and the soil subgrade to form a complete, stable containment system.

5. Polyethylene Geomembrane Applications: Where the "Work" Gets Done

Understanding how it works is best illustrated by where it works:

5.1 Landfills

Acts as the primary bottom liner and final cap, isolating municipal and hazardous waste from the surrounding environment, preventing leachate migration and controlling landfill gas.

5.2 Mining

Lines heap leach pads for copper/gold extraction and tailings impoundments, containing highly acidic or alkaline process solutions (pregnant leach solution) to protect local water resources.

5.3 Water Conservation

Lines canals, reservoirs, and decorative ponds to prevent seepage losses, a crucial technology in arid regions.

5.4 Aquaculture

Creates clean, controlled containment ponds for fish and shrimp farming.

5.5 Civil Infrastructure

Used in tunnel and roadway drainage layers, and as vapor barriers beneath building slabs.

Conclusion

Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) polyethylene geomembrane works not through complex mechanics, but through the elegant application of a material engineered for passive, resilient barrier performance. Its function is a symphony of impermeability, chemical inertness, mechanical strength, and environmental durability, all harmonized through precise manufacturing and conscientious installation. From safeguarding our groundwater beneath mountains of waste to preserving precious freshwater in arid climates, the polyethylene geomembrane is a foundational technology of modern environmental stewardship. It is a testament to human ingenuity—taking a simple polymer and transforming it into a durable shield that protects the very earth upon which we live.