Top Uses and Benefits of High Density Polyethylene HDPE Liners

In the complicated and regularly unseen infrastructure that underpins cutting-edge civilization, few substances play a function as pivotal but understated as high density polyethylene HDPE liners. These artificial liners are the silent, impermeable obstacles that protect our groundwater from contamination, tightly closed our potable water reserves, and allow a multitude of industrial, mining, and agricultural processes. As a engineered polymer imparting an awesome stability of durability, chemical resistance, and long-term cost-effectiveness, HDPE has emerged as the international cloth of desire for the world's most indispensable containment challenges. This in-depth article explores the molecular science, manufacturing processes, various applications, complicated set up protocols, and the long-term environmental lifecycle of HDPE liners, cementing their popularity as an quintessential device in the pursuit of a sustainable and technologically superior society.

1. What is High Density Polyethylene HDPE Liners?

To respect the overall performance of HDPE liner, one have to first apprehend the material at a molecular level. High Density Polyethylene is a thermoplastic polymer synthesized from the monomer ethylene via catalytic procedures like the Ziegler-Natta or Phillips method. The "high-density" designation is a direct end result of its linear molecular structure, characterised via minimal chain branching. This linearity approves the polymer chains to pack tightly collectively in a distinctly crystalline arrangement, forming a dense and strong cloth matrix. This necessary shape is the starting place of HDPE's famend suite of bodily and chemical properties:

1.1 Exceptional Durability and Tensile Strength

The tightly packed chains provide HDPE a excessive tensile strength, which means it can face up to huge pulling and mechanical stresses barring yielding or tearing. This is fundamental all through installation when the hdpe geomembrane is subjected to anxiety over uneven subgrades and when it have to help the static and dynamic hundreds of overlying soil and water.

1.2 Superior Chemical Resistance

HDPE pond liner is famend for its inertness. It famous a excessive diploma of resistance to a broad spectrum of aggressive chemicals, along with sturdy acids, bases, salts, and natural solvents. This makes it the premier desire for containing hazardous landfill leachate, acidic mine drainage, and industrial procedure fluids that would degrade lesser materials.

1.3 Effectively Impermeable Hydraulic Performance

The dense, crystalline shape creates an distinctly tremendous barrier to drinks and gases. The hydraulic conductivity of an geomembrane sheet is normally much less than 1 x 10⁻¹² centimeters per second, a price so low that for all realistic engineering purposes, it is viewed impermeable.

1.4 Resistance to Environmental Stress Cracking (ESCR)

High-quality hdpe liner pond-grade HDPE resins are in particular formulated to have a excessive resistance to Environmental Stress Cracking—a phenomenon the place a pressured plastic cracks in the presence of a chemical agent. This is a indispensable overall performance indicator for long-term integrity.

1.5 UV Resistance and Longevity

Pure HDPE can be degraded by way of extended exposure to ultraviolet radiation. To counter this, the resin is compounded with 2-3% carbon black, which acts as a effective UV stabilizer, successfully screening out hazardous rays and granting the liner a carrier lifestyles frequently projected to exceed 50 years, and in many covered applications, nicely beyond.

It is this effective and synergistic aggregate of characteristics that positions high density polyethylene pond liner as a most fulfilling solution, outperforming herbal substances like compacted clay and different polymeric options such as PVC or bendy polyolefins (FPO).

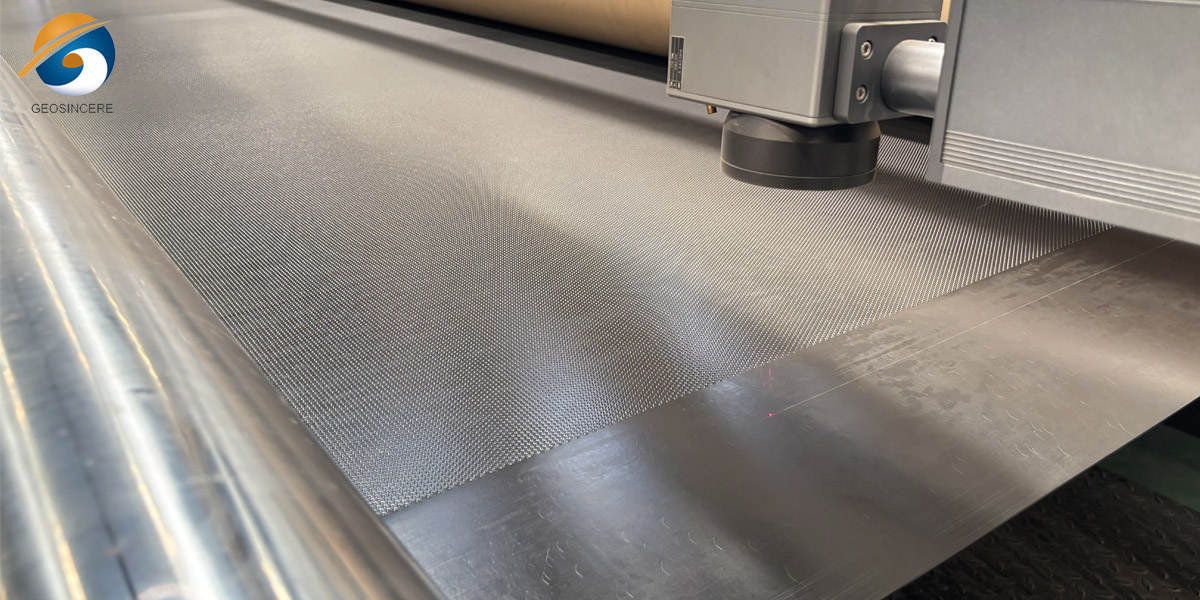

2. The Manufacturing Process: Engineering a High Density Polyethylene HDPE Liners

High density polyethylene liner is no longer simply manufactured; they are precision-engineered. The method is a state-of-the-art transformation from uncooked substances to a high-performance geosynthetic product.The ride starts with the manufacturing of HDPE resin in the structure of uniform pellets. These base pellets are then compounded in massive mixers with indispensable additives. The most quintessential of these is carbon black for UV stabilization, however the formula might also additionally consist of antioxidants to beautify long-term thermal steadiness and manner stabilizers. This compounded resin is then fed into a high density polyethylene geomembrane manufacturing line.

The predominant manufacturing technique is flat-die co-extrusion. In this process, the compounded resin is melted and pressured thru a wide, flat die, rising as a non-stop molten sheet. In co-extrusion, more than one layers are fused collectively in a single step, developing a homogenous sheet with regular thickness and improved properties. This technological know-how additionally allows the manufacturing of textured hdpe geo membrane. Texturing is carried out with the aid of introducing a patterned curler or via blowing gasoline onto the floor of the still-molten sheet, developing a roughened profile. Textured liners are imperative for purposes on slopes, as the floor roughness dramatically will increase the interface shear electricity between the liner and the adjoining soil or geosynthetic layers (like geosynthetic clay liners or geotextiles), thereby stopping catastrophic slippage and slope failure.

The last product is wound into large, heavy rolls. Modern manufacturing lets in for rolls up to 9 meters (30 feet) in width and heaps of meters in length. These giant panel sizes are a good sized advantage, as they limit the variety of discipline seams required, thereby improving the usual integrity and pace of the set up process.

3. High Density Polyethylene HDPE Liners:A Universe of Critical Applications

The versatility of hdpe geomembrane liner sees them deployed throughout a big and various spectrum of industries. Their major feature is constantly containment, however the nature of what they comprise varies dramatically, reflecting their fundamental position in environmental and monetary infrastructure.

3.1 High Density Polyethylene HDPE Liners for Environmental Protection and Waste Management:

3.1.1 Landfills: This is one of the most stressful applications. Modern sanitary landfills are engineered with composite liner structures the place a foremost hdpe geomembrane sheet varieties the key hydraulic barrier at the base and cap. It prevents leachate—a poisonous cocktail from decomposing waste—from infiltrating and polluting underlying aquifers. Simultaneously, the cap device isolates the waste from the surroundings and helps seize landfill fuel (methane) for flaring or strength production.

3.1.2 Water Containment: HDPE is used substantially to line wastewater therapy lagoons, equalization basins, and, critically, potable water reservoirs. Its inert nature ensures no unsafe chemical substances leach into the consuming water supply, whilst its impermeability ensures most conservation.

3.2 Mining and Heavy Industry:

3.2.1 Heap Leach Pads: In current metallic mining (for gold, copper, uranium, etc.), ore is overwhelmed and stacked on vast, HDPE-lined pads. A chemical answer (e.g., cyanide or sulfuric acid) is then irrigated over the ore heap, dissolving the goal metal. The hdpe liner sheet captures this "pregnant solution" and channels it to a processing plant, stopping any launch into the environment.

3.2.2 Tailings Impoundments: The fine-grained, regularly chemically reactive waste from mineral processing, regarded as tailings, is saved in massive, engineered impoundments. HDPE liners structure the base barrier in these structures, stopping the migration of poisonous metals and technique chemical substances into groundwater systems.

3.2.3 Industrial Process Ponds: Industries such as chemical manufacturing, energy generation, and pulp and paper remember on polyethylene pond liners to safely include procedure water, cooling water, brines, and different industrial by-products.

3.3 Water Conservation, Agriculture, and Aquaculture:

3.3.1 Canals and Irrigation Channels: In arid areas worldwide, lining water conveyance canals with HDPE extensively reduces water loss due to seepage, a vital effectivity measure for sustainable water management.

3.3.2 Aquaculture Ponds: Shrimp, fish, and different aquatic species farms rely on hdpe dam liners to create a controlled, hygienic environment. The liner prevents water loss, approves for environment friendly waste management, and eliminates seepage-related interactions with underlying soils.

3.3.3 Decorative and Fire Suppression Ponds: Used in municipalities, golf courses, and business properties, hdpe membrane sheet create dependable and long lasting water elements and emergency water storage reservoirs.

4. The Critical Art of High Density Polyethylene HDPE Liners Installation

A flawless hdpe geomembrane pond liner in a manufacturing unit roll is solely as appropriate as its discipline installation. This section is the place engineering format is translated into bodily reality, and it needs the absolute best stage of talent and satisfactory control. The single most imperative element is the introduction of strong, continuous, and watertight subject seams.The two major seaming techniques are:

- Fusion Welding (Dual-Track): This is the gold trendy for HDPE. A specialised welding machine, regularly a hot-wedge or extrusion-type welder, heats the overlapping edges of two liner panels to a molten state. They are then pressed together underneath force, efficiently re-constituting the molecular bonds and growing a single, homogenous piece of plastic. The hot-wedge approach creates a seam with two parallel channels. The integrity of each inch of this seam is confirmed on-site the use of a non-destructive air strain test, the place the channel is pressurized and monitored for stress decay.

- Extrusion Welding: This technique is used for element work, complicated geometries, patches, and repairs. A handheld extrusion gun deposits a ribbon of molten HDPE filler cloth over the seam area, fusing the underlying panels together.

The set up technique is a meticulous sequence of steps:

4.1 Subgrade Preparation: The basis soil should be meticulously graded, compacted to distinctive density, and free of any sharp rocks, roots, or particles that ought to puncture the liner. This is arguably the most necessary step for long-term performance.

4.2 Deployment and Panel Layout: The heavy rolls are strategically located and carefully unrolled throughout the organized subgrade in accordance to a pre-designed diagram sketch to limit seaming and waste.

4.3 Scanning: Highly skilled crews operate the welding, following strict protocols for temperature, speed, and pressure.

4.4 Quality Assurance and Quality Control (QA/QC): This is an ongoing technique involving visible inspection of each seam, damaging and non-destructive trying out of take a look at strips, and complete documentation.

4.5 Anchoring: The perimeter of the liner is securely positioned in an anchor trench, which transfers stresses and affords a tightly closed termination.

4.6 Protection: A shielding cowl layer, usually sand, chosen soil, or geotextiles, is positioned over the liner to defend it from UV degradation, bodily harm in the course of service, and doable flotation prompted by using wind or gasoline pressure.

5. High Density Polyethylene HDPE Liners:Sustainability and Lifecycle Considerations

In an technology centered on sustainability, the position of HDPE liners is profound. While derived from petrochemicals, their environmental advantages in software nearly continually some distance outweigh their preliminary carbon footprint. By stopping catastrophic groundwater pollution, conserving significant portions of water via seepage prevention, and enabling aid recuperation (e.g., in mining and waste-to-energy), they are a cornerstone of accountable industrial practice.

The long provider lifestyles of HDPE, frequently projected for 1/2 a century or more, potential it presents sustained safety with minimal maintenance. At the give up of its beneficial life, HDPE geomembrane material is technically recyclable. The enterprise is increasingly more exploring really useful reuse options, such as the use of decommissioned liners in choice each day covers for landfills, although the logistics of collection, cleaning, and reprocessing from far off websites continue to be an financial and realistic task that is the focal point of ongoing innovation.

Conclusion

Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) High Density Polyethylene HDPE Liners are a huge fulfillment in substances science and geotechnical engineering. They symbolize a ideal synergy of molecular understanding, rigorous manufacturing standards, and particular discipline craftsmanship. From developing a impenetrable barrier between our society's waste and its water provide to enabling the responsible extraction of sources and the conservation of treasured water, HDPE liners feature as an unseen however necessary guardian of our surroundings and our economy. As international challenges surrounding water scarcity, environmental protection, and useful resource effectivity proceed to intensify, the position of this robust, reliable, and versatile geomembrane will solely emerge as extra central, solidifying its legacy as a foundational science for a sustainable future.