How to Select the Right Geomembrane Sheet for Your Project?

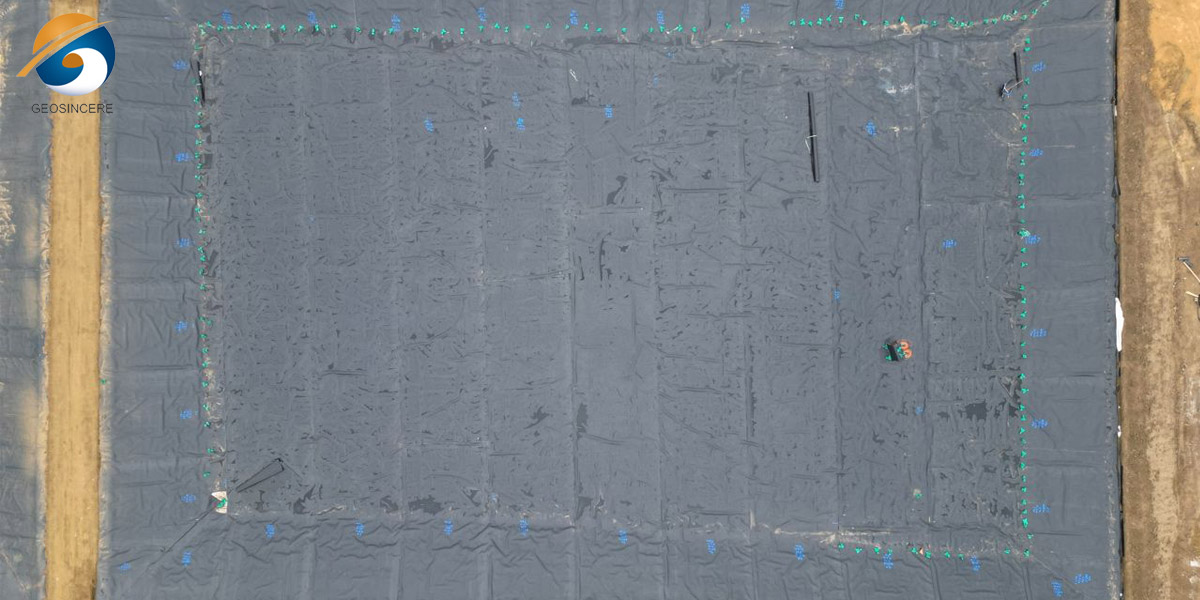

As infrastructure, environmental preservation, mining, and water management projects soar worldwide, the importance of geomembrane sheet cannot be overstated. In modern civil and environmental engineering, geomembrane sheets have become a vital component. They play an essential role in containment, waterproofing, and environmental protection not only in landfills and mining ponds but also in reservoirs, canals, and agricultural water storage.

Since GEOSINCERE Geosynthetics is a professional geosynthetics manufacturer and exporter with vast experience of serving the international market, we understand that project owners, contractors, and engineers often ask the same question: selecting the right geomembrane sheet for a particular project is a challenge to them. The use of an incorrect material, thickness, or specification can cause leakage, premature failure, regulatory non-compliance, and expensive repairs.

To help you with the decision, this guide covers all the aspects from explaining what are geomembrane sheets and their different types to key selection factors and gives practical recommendations based on actual applications. It is not only engineers that can take advantage of this article, but also procurement managers and project investors who will be able to make the right geomembrane choice for their project.

1. What is a Geomembrane Sheet?

A geomembrane sheet is a synthetic, low-permeability membrane that is mainly used as a barrier to control the movement of fluids or gases in engineering projects. HDPE geomembrane sheet is a type of geosynthetics and are usually made of polymeric materials like polyethylene, polypropylene, or polyvinyl chloride.

The fundamental role of a geomembrane is to contain. It stops liquids, chemicals, or gases from leaking into the soil or groundwater. Their great impermeability and durability have made them a staple in the following areas:

- Landfills and waste management sites

- Mining and heap leach pads

- Reservoirs and water bodies

- Canal lining systems

- Aquaculture and agriculture ponds

- Industrial wastewater treatment

- Oil & gas secondary containment

Today, geomembranes are designed to be resistant to a wide range of environmental conditions such as UV radiation, chemical exposure, temperature changes, and mechanical wear.

2. Why It Is Important to Choose the Right Geomembrane Sheet?

Choosing the right hdpe liner sheet should not be seen only as a matter of selecting the thickest or cheapest one. Each project is characterized by specific technical conditions, environmental factors, and legal requirements. Hence, an appropriate choice can guarantee the desired level of performance and reliability of the system over time.

2.1 An unsuitable choice of geomembrane material can bring about a number of severe consequences:

2.1.1 Leakage and Environmental Contamination

Degraded or inadequate materials may cause leaks through which contaminants spread into soil and groundwater, thus causing pollution, harm to humans and other living organisms, as well as regulatory concerns.

2.1.2 Structural Failure Caused by Mechanical Damage or Stress Cracking

Materials with insufficient mechanical strength and chemical resistance will be vulnerable to punctures, tears, and cracks when subjected to loading, temperature variations, or other adverse factors.

2.1.3 Shorter Service Life

The use of an incompatible hdpe membrane sheet may reduce drastically the lifetime of the system leading to early failure and replacement.

2.1.4 Escalation of Maintenance and Repair Costs

Recurring repairs, patching, or replacing parts will only add to the total maintenance cost and cause interruptions in the project's regular activities.

2.1.5 Failure to Comply with Local or International Standards

Deficient geo membrane sheet selection might lead to non-compliance with required standards or regulations and thus the incurrence of project delays or legal disputes.

2.2 On the other hand, a properly selected geomembrane offers clear advantages:

2.2.1. Longevity of the Service

The lifespan of a well-matched geomembrane liner system may be in the range of 20–50 years and even more, thus offering containment and protection over a long period.

2.2.2. Lowered Long-Term Operational Expenses

Since long-lasting and dependable hdpe geomembrane hardly ever need repairs or replacement, the overall lifecycle costs are greatly reduced.

2.2.3. Upgraded Environmental Safety and Legal Compliance

Proper selection not only contributes to improved environmental protection but also supports leakage prevention and makes it easier to conform to both local and international environmental rules.

2.2.4. Strengthened Project Reliability in General

By picking the right hdpe membrane one can expect better performance of the system, less risk, and greater trust in the project’s long-term accomplishment.

Thus, one cannot afford to overlook hdpe geomembrane liner selection criteria when considering any purchase or design decision.

3. Most Popular Types of Geomembrane Sheet Materials

The first stepping stone in the choice of an appropriate geomembrane sheet is breaking down the various materials that are in the market. Each type of geomembrane material comes with a set of pros and cons as well as its application field suitability.

3.1 What is HDPE Geomembrane Sheet (High-Density Polyethylene)?

Due to their great toughness and chemical resistance, HDPE hdpe liner sheet make up the main part of the global geomembrane market. Their selection is typically for the projects which have environmental and engineering risks that are challenging to contain.

3.1.1. Exceptional Chemical Resistance

This type of impermeable geomembrane is highly resistant to an extensive range of chemicals, which includes acids, alkalis, and industrial contaminants. This feature enables them to be used in areas with aggressive chemicals and materials.

3.1.2. Outstanding UV Resistance

Due to their extreme resistance to ultraviolet radiation, HDPE geomembranes can deliver continuously good performance even after long-term exposure to outdoor conditions.

3.1.3. Low Permeability

HDPE has such a low permeability level that it can very successfully block the migration of liquids and gases, thus enabling it to be used as an effective containment barrier.

3.1.4. Strong in Tensile

The geomembrane hdpe 2mm material, because of its high tensile strength, can resist very well to heavy loads, ground settlement, and installation and service stresses.

3.1.5. Long-lasting

HDPE geomembranes when expertly installed, can give a service life of decades even though they are subjected to harsh environmental conditions.

3.1.6. Typical Fields of Application

People use HDPE geomembranes in landfills, mining projects, industrial wastewater ponds, as well as the systems designed for the containment of hazardous waste.

HDPE impermeable geomembrane liner is perfect for uses where there is a need for long-lasting durability and resistance to aggressive chemicals. On the other hand, compared to other geomembrane types, they are somewhat stiff and may not be as flexible at low temperatures.

3.2 What is LLDPE Geomembrane Sheet (Linear Low-Density Polyethylene)?

LLDPE geomembrane liner is developed to have a higher degree of flexibility along with good mechanical and chemical properties. Basically, they can be selected for subgrades that happen to be uneven or for shapes that are complicated to ask for.

3.2.1 More Elongation and Flexibility

Geomembranes made of LLDPE have a larger elongation at break, which essentially means they will be better able to tolerate ground movement and uneven surfaces.

3.2.2 Chemically Resistant

This lldpe geomembrane material retains its resistance against many of the common chemicals and thus can be used in a wide variety of containment areas.

3.2.3 Better Stress Crack Resistance

Because of the improved stress crack resistance in LLDPE, there is less danger of failure due to long-term mechanical loading and deformation.

3.2.4 Typical Applications

Geomembrana lldpe is most frequently used for irregular subgrades, decorative or landscape ponds, and projects that involve complex shapes.

The main reason why LLDPE is used is when flexibility is a point of concern. But, it is generally less stiff than HDPE geomembranes.

3.3 PVC Geomembrane Sheet (Polyvinyl Chloride)

PVC geomembranes are well known for their softness and ease of handling, making them suitable for projects requiring high flexibility and simple installation.

3.3.1 Easy Installation

PVC geomembrane is lightweight and flexible, allowing for quick installation with minimal specialized equipment.

3.3.2 High Flexibility

The pvc geomembrane liner material remains flexible, even in low-temperature environments, making it suitable for applications where movement is expected.

3.3.3 Good Performance in Low Temperatures

PVC maintains flexibility in colder climates, reducing the risk of cracking during installation and use.

3.3.4 Typical Applications

PVC geomembranes are commonly used in water features, temporary containment systems, and roofing or architectural waterproofing projects.

Compared to HDPE, PVC geomembranes generally have lower chemical resistance and a shorter service life, particularly in harsh chemical or outdoor environments.

4. Key Factors to Consider When Selecting a Geomembrane Sheet

Choosing the right geomembrane requires evaluating multiple technical and environmental factors.

4.1 Project Application and Purpose

The first and most important question is: What is the geomembrane being used for?

Different applications impose different demands:

Landfills require high chemical resistance and puncture strength

Water reservoirs prioritize impermeability and UV resistance

Mining projects demand resistance to aggressive chemicals and high temperatures

Clearly defining the project purpose will narrow down suitable materials.

4.2 Chemical Compatibility

If the geomembrane will be exposed to chemicals, leachate, or contaminated liquids, chemical compatibility is critical.

HDPE impermeable liner generally offer the highest resistance to acids, alkalis, and hydrocarbons. Before final selection, it is recommended to conduct chemical compatibility testing or consult experienced manufacturers like GEOSINCERE Geosynthetics.

4.3 Thickness Selection

Geomembrane thickness is typically measured in millimeters (mm) or mils.

Common thicknesses include:

- 0.5 mm – 0.75 mm: light-duty applications

- 1.0 mm – 1.5 mm: medium-duty containment

- 2.0 mm or thicker: heavy-duty, high-risk projects

Thicker high density polyethylene geomembrane generally provide better puncture resistance and durability, but they also increase cost. Thickness should be selected based on project risk, subgrade conditions, and regulatory requirements.

4.4 Mechanical Properties

Important mechanical properties include:

- Tensile strength

- Elongation at break

- Tear resistance

- Puncture resistance

Projects with sharp subgrades or heavy loads require geomembranes with higher mechanical strength.

4.5 Environmental Conditions

Environmental factors such as temperature range, UV exposure, and wind conditions must be considered.

For example:

Projects in hot climates require excellent UV and thermal resistance

Cold regions require flexible reinforced polypropylene geomembrane that resist cracking

HDPE geomembranes with carbon black additives offer superior UV stability for outdoor exposure.

4.6 Installation Method and Site Conditions

Installation conditions can significantly influence material selection.

Uneven or rocky subgrades may require more flexible membrane hdpe

Large projects benefit from wider rolls to reduce seams

Remote locations may require easier handling and welding

Understanding site constraints helps optimize installation efficiency and quality.

Conclusion

Selecting the right geomembrane sheet for your project is a critical decision that affects performance, safety, and cost throughout the project lifecycle. By understanding material types, key selection factors, and application-specific requirements, you can make an informed and confident choice.

At Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) , we are committed to providing high-quality geomembrane solutions tailored to global engineering and environmental projects. If you are planning a project and need expert guidance, our technical team is ready to support you from design to installation.

Choosing the right geomembrane sheet today means protecting your investment and the environment for decades to come.