Why Use Clay Liner in Landfill ?

The administration of municipal strong waste is one of the most urgent environmental challenges of our time. As international populations and consumption prices rise, so does the quantity of waste destined for landfills. Historically, these websites have been little extra than open dumps, permitting leachate—a poisonous cocktail of water and dissolved contaminants—to seep freely into the surrounding soil and groundwater, posing severe dangers to public fitness and ecosystems. The cutting-edge engineered landfill, however, is a rather state-of-the-art containment machine designed to isolate waste from the environment. At the coronary heart of this machine lies a reputedly humble but profoundly vital component: the clay liner. This article delves into the science, engineering, construction, and enduring function of geosynthetic clay liner as the most important barrier in opposition to air pollution in waste containment facilities.

1. Clay Liner in Landfill The Science Behind the Barrier: Why Clay Works

Clay, in particular sodium bentonite, is the cloth of desire for landfill liners due to its special geotechnical properties. The effectiveness of clay as a barrier hinges on three key characteristics: low hydraulic conductivity, attenuation capacity, and durability.

1.1 Low Hydraulic Conductivity

The important feature of a clay liner is to be as impermeable as possible. Hydraulic conductivity (often referred to as permeability) is a measure of how without difficulty a fluid can cross via pore areas in a soil. Coarse-grained soils like sand and gravel have excessive permeability, permitting water to drift thru quickly. Clay, in contrast, is composed of extraordinarily fine, plate-like particles. These particles create a dense, tortuous community of microscopic pores. When compacted at the right moisture content, these pores come to be so small and interconnected that the motion of water is severely restricted. Regulatory standards, such as these from the U.S. Environmental Protection Agency (EPA), generally mandate that geosynthetic liner used in landfills ought to gain a hydraulic conductivity of 1 x 10⁻⁷ cm/s or less. This ability it would take many years or even centuries for a tremendous extent of leachate to migrate via a excellent built clay layer.

1.2 Attenuation Capacity

Beyond in reality performing as a bodily barrier, clay minerals possess a effective chemical property recognized as cation trade potential (CEC). The surfaces of clay particles are negatively charged, which approves them to appeal to and continue positively charged ions (cations) many times determined in leachate, such as heavy metals (e.g., lead, cadmium, arsenic). This process, known as attenuation or sorption, successfully filters and immobilizes these hazardous contaminants, stopping them from migrating into the groundwater. While this capability is no longer infinite, it presents a fundamental secondary line of defense, retarding the motion of pollution even if some moisture manages to permeate the gcl pond liner.

1.3 Durability and Self-Healing

Unlike artificial materials, which can be prone to chemical degradation or tearing, geocomposite clay liner provide long-term stability. They are normally resistant to the chemical compounds located in leachate. Furthermore, clay possesses a diploma of self-healing capability. If a small crack varieties due to desiccation or settlement, the clay can swell upon re-wetting, efficaciously sealing the fissure and restoring its low-permeability characteristic. This resilience is essential for a shape that ought to operate its containment characteristic for a long time after a landfill has been closed.

2. The Anatomy of a Clay Liner in Landfill

In cutting-edge landfill design, a geocomposite clay liner is not often used alone. It is nearly usually phase of a multi-layered, composite gadget that leverages the strengths of one of a kind substances to create a extra sturdy barrier. A traditional cross-section from the backside up includes:

2.1 Prepared Subgrade

The native soil is excavated and graded to a particular slope to facilitate leachate collection. It is then closely compacted to furnish a secure foundation.

2.2 Clay Liner (Compacted Clay Liner - CCL)

This is the core herbal barrier. A layer of appropriate clay, generally 0.6 to 1 meter thick, is positioned in more than one compacted lifts. Each geo clay liner is meticulously examined for moisture content, density, and, most importantly, carried out permeability.

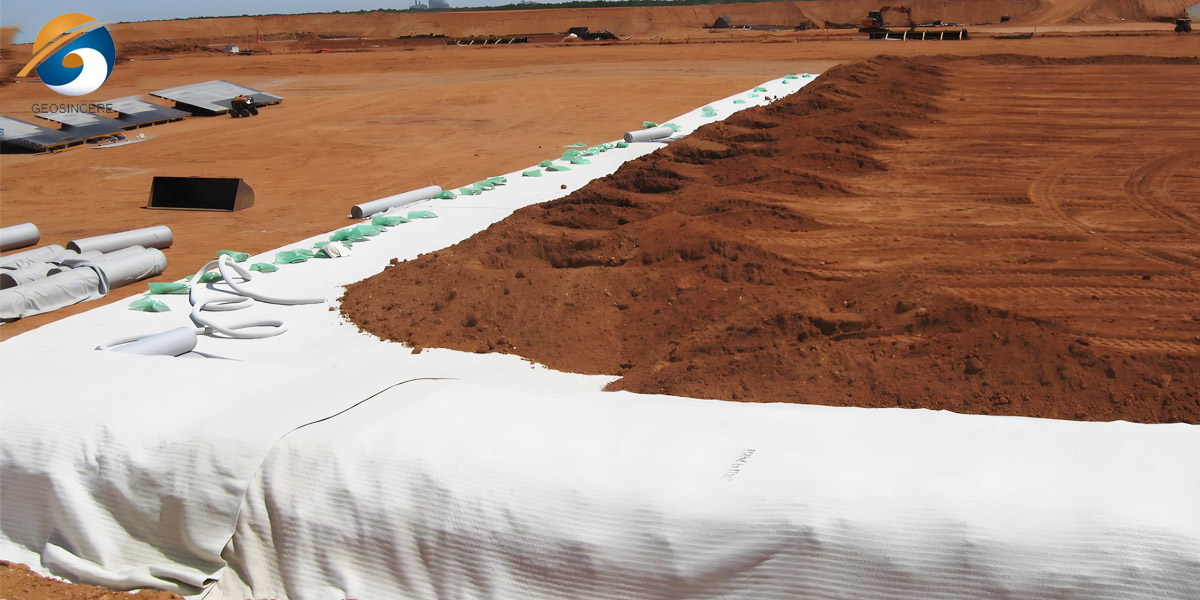

2.3 Geosynthetic Clay Liner (GCL)

Often hooked up above or once in a while in vicinity of a component of the CCL, a bentomat geosynthetic clay liner is a factory-manufactured hydraulic barrier consisting of a layer of bentonite clay sandwiched between two geotextiles or bonded to a geomembrane. GCLs are famous for their ease of set up and regular properties, serving as an brilliant complement to the ordinary CCL.

2.4 Flexible Membrane Liner (FML - Geomembrane)

This is a artificial layer, generally made from high-density polyethylene (HDPE), which is positioned without delay on pinnacle of the clay liner landfill. The geomembrane is extraordinarily impermeable and acts as the fundamental bendy barrier.

2.5 Protective Layer and Leachate Collection System

A layer of gravel or a geocomposite internet is positioned over the geomembrane to defend it from puncture. This layer additionally serves as the major conduit for the leachate series system, a community of pipes that actively collects and pumps out leachate for therapy earlier than it can construct up and exert good sized hydraulic stress on the underlying liners.

The synergy between the bentomat pond liner and geomembrane is what makes this composite machine so effective. The geomembrane acts as the first and most instantaneous barrier. However, any small holes or defects in the geomembrane (which can show up all through set up or from long-term stress) are backed up with the aid of the clay layer. The clay liner then acts as a secondary, fail-safe barrier, making sure that the average system's integrity stays intact.

3. Clay Liner in Landfill - Ensuring Performance

The theoretical homes of clay are meaningless besides unique and quality-controlled construction. Building a high-performance gcl clay liner is a meticulous process.

3.1 Material Selection

Not all clays are suitable. The soil ought to be examined for its gradation, plasticity index (a measure of its clayey nature), and its capacity to be compacted to the required low permeability.

3.2 Moisture and Compaction Control

This is the most quintessential phase. The clay need to be positioned at or close to its "optimum moisture content"—the water content material at which it can be compacted to its most density and minimal permeability. If the clay is too dry, it will now not bind excellent and will shape clods and voids. If it is too wet, it turns into smooth and unstable. Heavy machinery, such as sheepsfoot compactors, is used to knead and compress the clay in skinny lifts, making sure uniformity and disposing of air pockets.

3.3 Quality Assurance/Quality Control (QA/QC)

Throughout construction, impartial technicians and engineers habits non-stop testing. Field density exams (e.g., the use of a nuclear density gauge) and laboratory permeability checks on field-collected samples are carried out to affirm that each and every part of the liner meets the stringent regulatory standards.

4. Limitations and the Future of Clay Liner in Landfill

Despite their verified effectiveness, clay liners are no longer except limitations. Their overall performance can be compromised by means of sure aggressive chemical leachates that can alter the clay's shape and extend its permeability over time (a method recognised as chemo-mechanical degradation). Furthermore, desiccation and cracking can appear if the gcl geosynthetic clay liners is uncovered to severe drying prerequisites earlier than being covered.

The future of landfill liners lies in the persevered evolution of composite systems. Research is centered on bettering the homes of clay, such as by way of treating bentonite with polymers to enhance its chemical resistance. The use of bentonite geosynthetic clay liner is turning into greater widely wide-spread due to their overall performance consistency. Ultimately, the intention is now not simply to comprise waste however to transition closer to a extra round economic system that minimizes waste technology altogether. However, as lengthy as landfills continue to be a vital section of our waste administration infrastructure, the clay liner in landfill, in partnership with artificial materials, will proceed to serve as an imperative impermeable shield, defending our treasured water sources for generations to come.

Conclusion

The clay liner is a testomony to the precept that fantastic environmental engineering frequently includes working with and bettering herbal systems. From its critical scientific residences of low permeability and chemical attenuation to its engineered function inside a composite liner system, the clay liner offers a robust, durable, and self-healing barrier towards pollution. Its profitable implementation relies upon on a rigorous technique of fabric selection, moisture control, and compaction, all underpinned by means of relentless high-quality assurance. While artificial geomembranes supply the first line of defense, the clay layer under presents the critical, long-term safety required for such a everlasting environmental structure. In the silent, hidden world below our landfills, the geotextile clay liner stands as a silent guardian, an impermeable guard diligently defending the biosphere from the byproducts of human consumption.

Choosing a Reliable Clay Liner in Landfill Supplier

Shandong Geosino New Material Co., Ltd (Brand: GEOSINCERE Geosynthetics) is a professional manufacturer, exporter, and wholesaler of geosynthetic products, including Geosynthetic Clay Liners, HDPE Liners, geotextiles, geogrids, geocells, and drainage boards, based in Shandong, China. With over 10 years of experience exporting to more than 100 countries, including Australia, France, UK, Brazil, India, UAE, and South Africa, Geosincere has earned a reputation for high-quality, durable, and cost-effective products. Investing over $10 million in state-of-the-art automatic production lines, Geosincere continuously improves technology, manufacturing processes, and turnkey engineering capabilities. Our geosynthetics are designed to meet demanding civil, mining, and environmental challenges, offering innovative engineering solutions, quality assurance, factory prices, and fast delivery to ensure customer satisfaction worldwide.